Thread: CNC design for consideration

-

10-04-2012 #11

told you it would be silly not giving him a shout :)

only three screws ?? if you are not using two screws on your x axis id have a good think about the implications before you press buy

that extra screw will more than earn its keep!

your design shows four screws? have you already got one for your Z axis?

-

10-04-2012 #12

That sounds OK to me, as I said before he's 110% genuine.

John S -

-

10-04-2012 #13

Yes! Definitely get 2 for the X axis...

Price sounds about right for Chai. I always pay him directly via a paypal invoice as I think he knocks a bit off due to no eBay fees.

Customs recently changed the rules - now everything above £18 value stated on the form gets charged. I don't really mind paying the VAT but £10 handling fee is just extortionate. Last time I just tried paying the VAT (£4.08) and not the handling charge (£10)... so far so good!

Expect to pay another £20 or so since it's a reasonable size order.

-

10-04-2012 #14

-

10-04-2012 #15

I've already paid for shipping to my door, not Heathrow, so the £10 appears to be to send one letter and collect the money. For the most part it will be an automated system so I don't see how it can cost them £10 to do that - they're clearly trying to make a bit of money. The handling charges used to be much less, and before that they were illegal - I'd happily pay £3-4. Even sending the letter via Royal mail doesn't cost that much!

-

10-04-2012 #16

Sorry, didn't realise it was illegal for a company to try to make a bit of money.

You could always collect from ChiJohn S -

-

10-04-2012 #17

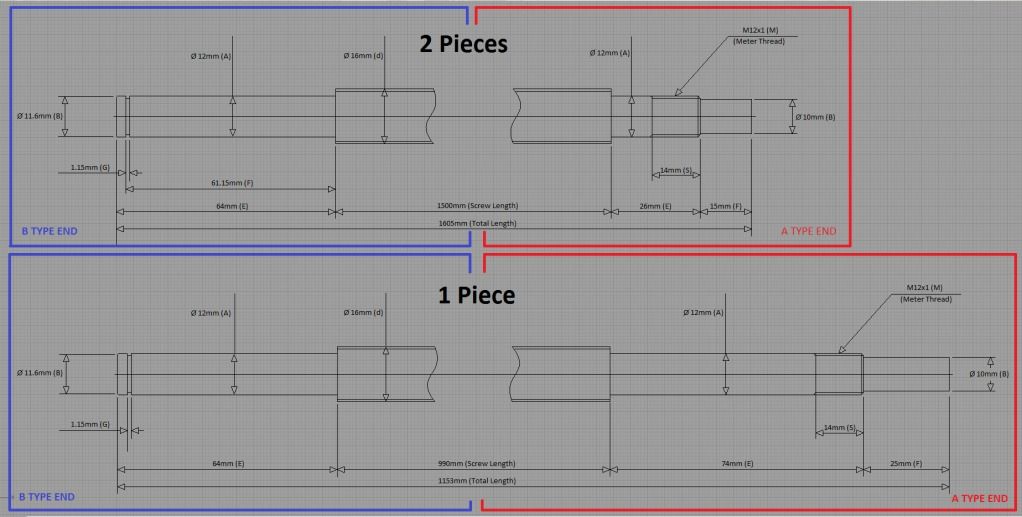

So its all ordered then! Very nice guy. He sent me the standard drawings for the machined ends and I had a peruse to see if they would fit my machine and wouldn't. So I simply emailed him my requirements and he has not charged me anything extra! I will definitely do business with him again. The screws I ordered are just for x and y. i need to redesign the z axis because I'm not sure I want to go with round rail. I think there will be too much deflection at the cutter so ill just buy another smaller ballscrew when I'm ready for it. I want to change the bed too. Here's what I ordered screw wise. I'll create a build log when I get all my parts together. Can't wait :)

-

01-05-2012 #18

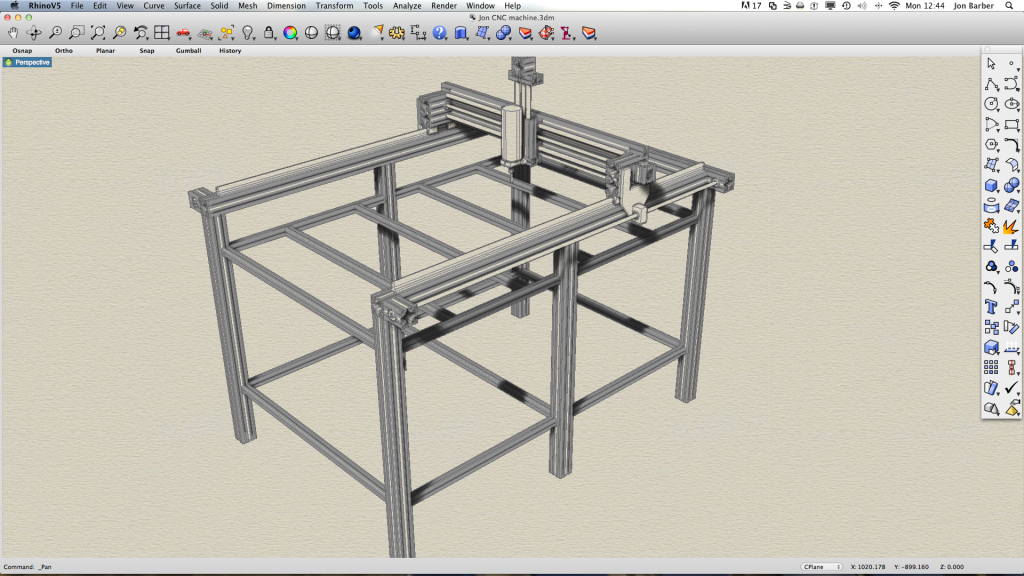

Hi The Y axis looks like it is set on one side; if it is, this will jam as the axis drive needs to be central or with two stepper drives simultaneously operated one on each side of the machine. I would also consider widening the Y axis bearings so the machine has less Y wobble. As you are only cutting MDF and Plywood accuracy is not an isse here that design is good enough. If you can squeese a bit more out of your budget, go for the linier bearings as in the photo.

These are far more accurate and rigid and will increase rigidity and production speed. Keeping this design square in the X & Y plane is going to be dificult.

-

01-05-2012 #19

-

16-05-2012 #20

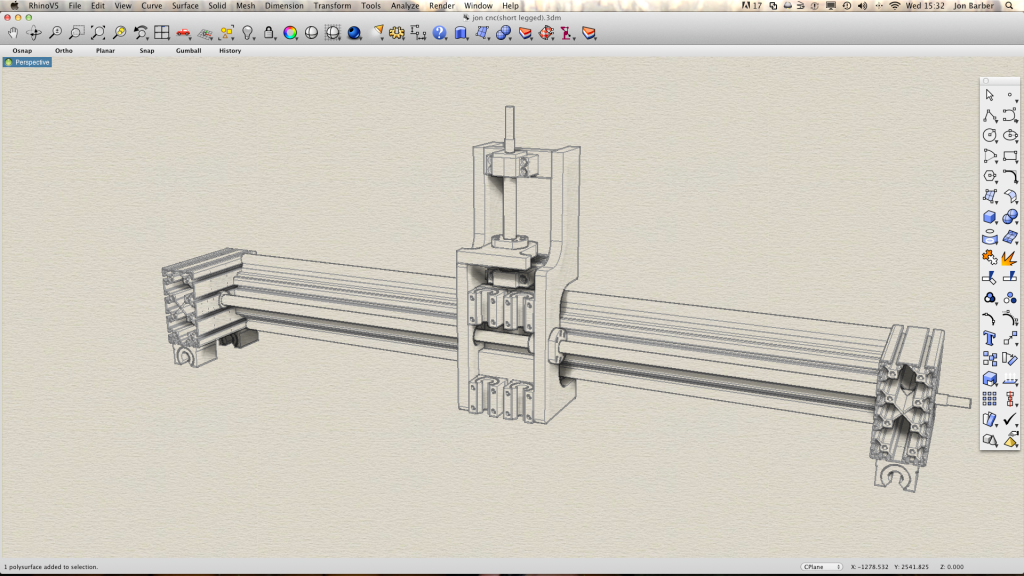

Hi guys, been really busy lately so updates will be few and far between. Im collecting my parts together at the moment but just wanted to show you a revised y and z axis on my machine and see what you think. Ive moved the rails above and below and gone for supported on z. Ive tried to make z as light and thin as possible so I can get more movement on y. As for the previous design LotusPack, it is driven from both sides you just cant see it because of the angle of the drawing that's all. I considered going for profile rails but I don't want to spend that amount on a first build. Maybe the next one ;)

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Interesting Papers on heavy duty design, vibrations, composites and column design

By D.C. in forum Gantry/Router Machines & BuildingReplies: 15Last Post: 25-06-2016, 10:13 PM -

Design Help Pt2 Required for CNC design/Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 38Last Post: 21-07-2014, 02:05 PM -

RFQ: Pre-RFQ Design

By Hutchie in forum Projects, Jobs & RequestsReplies: 11Last Post: 05-02-2012, 06:45 PM -

Design help etc required with DIY CNC Router Design / Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 12Last Post: 21-10-2011, 04:50 PM

Reply With Quote

Reply With Quote

Bookmarks