-

16-02-2017 #11

Spent a few hours looking into control boards and stuff.

People where saying the parallel boards that come with the China CNC machines are not worth it (because they are limited to just doing stepper control) so I would rather not use them.

Boards like the TinyG are controllers in themselves (I thought they worked with Mach3, bad YouTubers misleading me there), they don't run with software like Mach3 because they are hardware controllers.

They take the Gcode and control the motors, while Mach3 is a softwarecontroller that sends the movement data/signals to the drivers directly via serial or other interface.

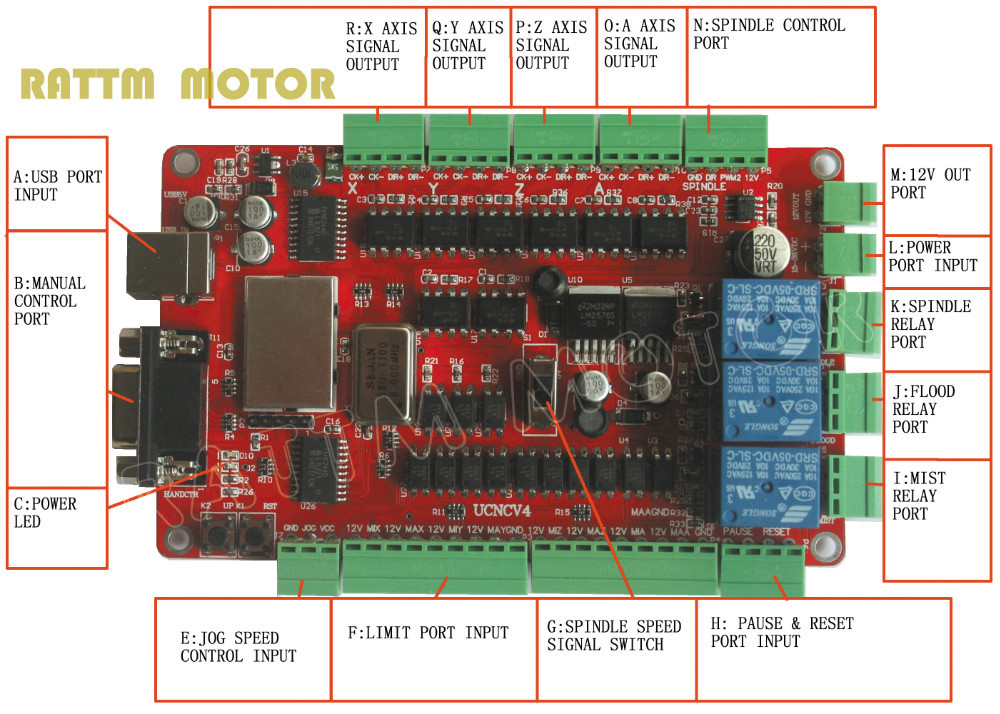

I think what I am after is one of these "breakout boards".

This one (which comes with a lot of the stepper kits) http://www.ebay.co.uk/itm/262849334835

Looks to be what I am after.

4 Axis (only need 3) stepper control, spindle PWM, 3 relays for pump, air etc, home/limit switches and a couple IO ports.

Still China made but it comes with the motor kit so it should work fine with that setup.

That is the thing. I am not expecting more than 100. Probably not even 50. But at least 25 to make it worth doing the production run.

I have always wanted a CNC table/mill. I want to do a few personal wood projects and some 5-10mm aluminium plate and I think now is a good time to get one.

That rail is a concern. There have been a few videos demonstration this but for what I am doing I don't think it will be that bad?

Most said it was okay though larger jobs it started to cause problems.

I really do like the idea of putting a kit together rather than buying a premade one.

http://www.ebay.co.uk/itm/EU-Stock-4...QAAOSwDFNWFJQE

This one looks the the standard 6040 and is around ~£1,500

But I could put together this kit together for around £1,200. But I get the upgraded 2.2kW spindle, controller and beefer steppers.

Base - £650 - https://www.aliexpress.com/item/6040...308.0.0.4cDNN7

2.2kW spindle/driver - £200 - http://www.ebay.co.uk/itm/252593036650

Steppers - ~£230 - https://www.aliexpress.com/store/pro...612.0.0.NtqLm6

Stepper mounts - ~£15 - Trying to find some EU stock. Only China atm :/ https://www.aliexpress.com/item/3Pcs...999.268.f7AXAm

Cables, Water pump, Tube, cable bendy thing etc - ~75-100

Sounds like a better deal to me...Last edited by JOGARA; 16-02-2017 at 09:47 PM.

-

16-02-2017 #12

The problem with "kits" of parts, especially electronics is that they are not well matched. The stepper motors will probably be high inductance ones, the switch mode PSU will be underated and so it wont run as well as it should. You'd be far better off getting your motors from Zapp or somewhere like that where they'll be good ones.

As. You're electrically minded building a custom P S U should be a breeze...

Sent from my HUAWEI VNS-L31 using TapatalkLast edited by njhussey; 16-02-2017 at 11:18 PM.

-

16-02-2017 #13

Ill take a look at the Zapp stuff, thanks.

As for the power supply, if I get my motors from Zapp I can get an OP supply.

Those Chinese switch modes are pretty good though. I have a 12v one powering a lot of stuff in my workshop 24/7 as well as my 3D printer and CCTV system.

-

16-02-2017 #14

The switch mode ones don't take back EMF from the drivers when the machine is decelerating. If you make a linear PSU with some nice big caps then this is best, and you can make it to the ideal voltage. You really want some nice 80V drivers and a 72V PSU...then it'll fly which is what you need to cut plastic. I cut UHMWPE at 8000mm/min, your matched set wont get near that.

Sent from my HUAWEI VNS-L31 using Tapatalk

-

The Following User Says Thank You to njhussey For This Useful Post:

-

16-02-2017 #15

-

16-02-2017 #16

Yes, have a read through the build logs...plenty have done them.

Sent from my HUAWEI VNS-L31 using Tapatalk

-

17-02-2017 #17

-

17-02-2017 #18

Isn't there a way to dump excess power coming back from steppers?

Like resistors or something.

-

17-02-2017 #19

Unfortunately not. There are two main problems with the switch-mode PSUs in this application, although they are great and very cost-effective elsewhere. One is the back emf issue as mentioned, while linear power supplies dump excess power into the smoothing caps (one way to look at it, anyway). The other is that linear supplies are much more tolerant of peak overload. A switch-mode supply tends to hard-limit, maybe even shut down temporarily, if you try to draw more than rated current where a linear supply output will tend to just sag a bit which is not usually a problem. If you are now looking at Mach3, you might also consider something like a UC100 or UC300 with UCCNC which is looking like an attractive option these days. Still need a break-out board but it's a better option than using Mach3 and parallel port.

-

17-02-2017 #20

Okay, so I looked into toroidal based supplies and they are easy to make. So should be no time to spin a board for one of those.

Do cost a bit to get them off the self, though I know of a place that do them for like 50 euros each at any spec you want.

So might be able to get a decent high amp one for not that much more.

The problem is, the high voltage stepper controllers are not Chinese cheap :p

Looking at £110 per axis :/

I have only looked on Zapp though so far.

Steppers themselves are around £30 each. Makes it around double the cost.

But I guess it is worth it because of needing that extra speed and power?

Regarding the steppers, they state a "Rated Voltage" of around 2-4v.

Do the drivers lower to voltage or because they pulse the stepper they are able to use upwards of 80v?

Thread Information

Users Browsing this Thread

There are currently 36 users browsing this thread. (0 members and 36 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks