Threaded View

-

16-02-2017 #10

Spent a few hours looking into control boards and stuff.

People where saying the parallel boards that come with the China CNC machines are not worth it (because they are limited to just doing stepper control) so I would rather not use them.

Boards like the TinyG are controllers in themselves (I thought they worked with Mach3, bad YouTubers misleading me there), they don't run with software like Mach3 because they are hardware controllers.

They take the Gcode and control the motors, while Mach3 is a softwarecontroller that sends the movement data/signals to the drivers directly via serial or other interface.

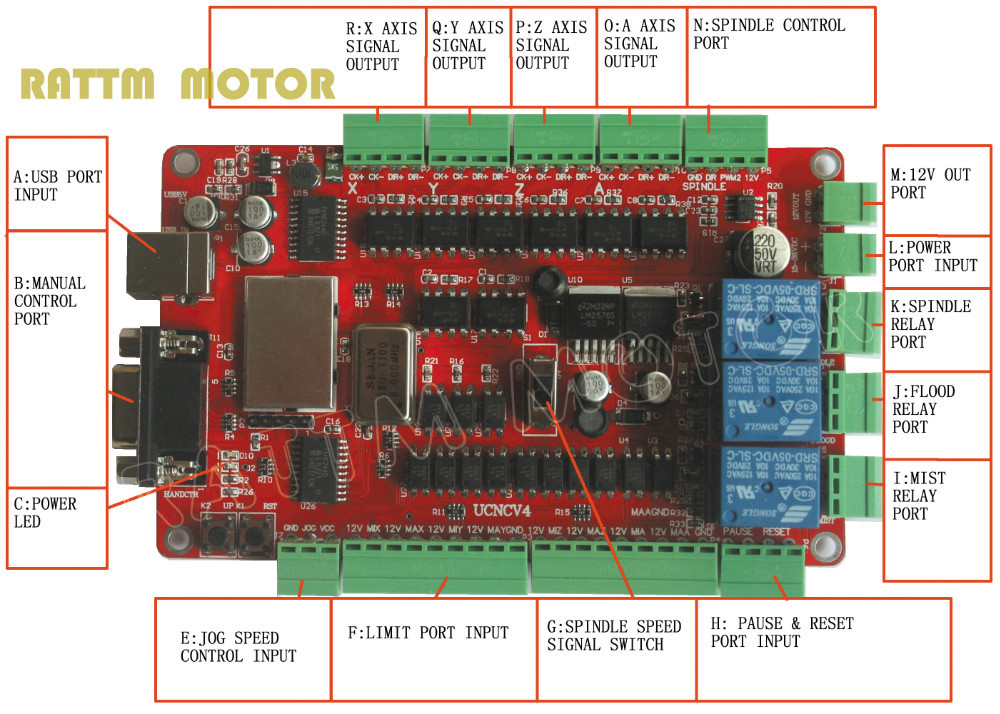

I think what I am after is one of these "breakout boards".

This one (which comes with a lot of the stepper kits) http://www.ebay.co.uk/itm/262849334835

Looks to be what I am after.

4 Axis (only need 3) stepper control, spindle PWM, 3 relays for pump, air etc, home/limit switches and a couple IO ports.

Still China made but it comes with the motor kit so it should work fine with that setup.

That is the thing. I am not expecting more than 100. Probably not even 50. But at least 25 to make it worth doing the production run.

I have always wanted a CNC table/mill. I want to do a few personal wood projects and some 5-10mm aluminium plate and I think now is a good time to get one.

That rail is a concern. There have been a few videos demonstration this but for what I am doing I don't think it will be that bad?

Most said it was okay though larger jobs it started to cause problems.

I really do like the idea of putting a kit together rather than buying a premade one.

http://www.ebay.co.uk/itm/EU-Stock-4...QAAOSwDFNWFJQE

This one looks the the standard 6040 and is around ~£1,500

But I could put together this kit together for around £1,200. But I get the upgraded 2.2kW spindle, controller and beefer steppers.

Base - £650 - https://www.aliexpress.com/item/6040...308.0.0.4cDNN7

2.2kW spindle/driver - £200 - http://www.ebay.co.uk/itm/252593036650

Steppers - ~£230 - https://www.aliexpress.com/store/pro...612.0.0.NtqLm6

Stepper mounts - ~£15 - Trying to find some EU stock. Only China atm :/ https://www.aliexpress.com/item/3Pcs...999.268.f7AXAm

Cables, Water pump, Tube, cable bendy thing etc - ~75-100

Sounds like a better deal to me...Last edited by JOGARA; 16-02-2017 at 09:47 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks