Thread: What would YOU do with all this?

-

05-11-2018 #1

Also posted on CNCzone.

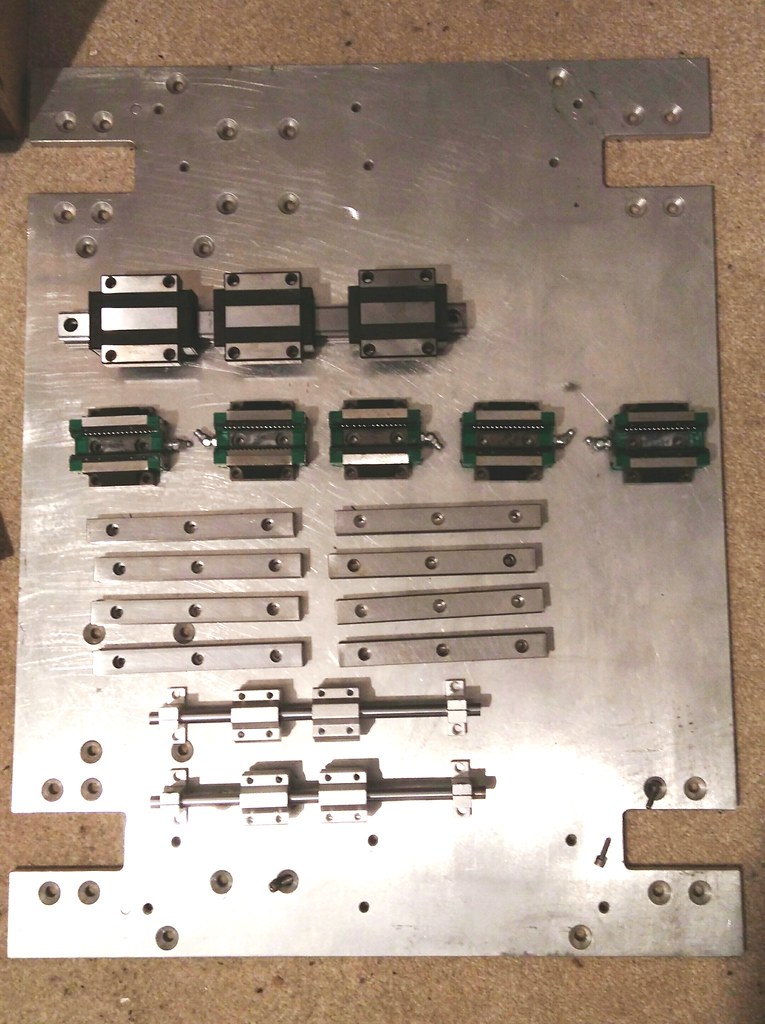

So its a regular Friday night in September. You're chilling at home watching Judge Judy, when there is a knock on the door. You open it and Santa hands you this.

What we have here is:

3x THK HSR25 carriages and one 25mm rail, 320mm long. All genuine and in ok condition.

5x INA KWVE20B carriages and 8x 20mm rails, each 160mm long. Again, all genuine.

4x SC10UU bearings with end supports and 250mm long rods.

Now you have a dilemma. Ideally you need multiples of 4 carriages per axis on a CNC machine, but due to the length of the rails, and the fact that you only have three THK carriages this becomes a problem.

So, what would you do/make with these parts? Something useful like a fairly accurate desktop cnc machine? A lathe?

Here are the rules:

1. You have no money for more bearings etc. You do have just enough for the spindle and electronics.

2. Rails CAN be cut and joined together.

3. You can't sell everything on ebay.

4. You have access to tons of aluminium extrusion and this lovely 12mm aluminium surface plate 700x550 wide.

Me? Well I'm trying to build my 3'x2' cnc router, and I'd love to have a small machine to make the smaller parts with, out of aluminum. It would also be nice to have a cnc router in a quiet box in my room, on the table perhaps.

TLDR: Got some free stuff and now I need to find a way to make it work for me. Any ideas? No naysayers! I don't believe in can't.

Aaaaaaand GO!

-

05-11-2018 #2

The carraiges are the expensive part and the rail is cheaper so if you can get some compatible rail in a useful length then do that (sorry, some cash required here).

Use the unsupported rail for Z, the three large carraiges for the Y (one on top rail and 2 on the lower rail where the forces are higher). Use the 4 small carraiges on the long X axis that the gantry rides on, with one spare.

Use the profiles for gantry and bed with the plate for gantry sides and any spare plate for a spoil board / work area

Save up for ballscrews plus the rest.

Unfortunately CNC can’t be done cheaply but the above would get a fun starter machine. Make a nice job and maybe get more for it to put towards mk2? Best of luck with it !

-

05-11-2018 #3

You have broken rule no.1

Firstly, I love your video series on Youtube. Great clean work on MK4 mate! Absolute joy watching you work.

Firstly, I love your video series on Youtube. Great clean work on MK4 mate! Absolute joy watching you work.

I have absolutely everything I need for my 3'x2' build. Yes it cost money!

These parts are just for something fun and perhaps useful. I'm not buying anymore for it.

Interestingly, I've already put together a build in sketchup using only these parts and a short chunk of aluminium extrusion (120x80mm heavy duty). It sort of looks more like a milling machine than a cnc but still. For lead screws I use regular M8 threaded rod and some acetal as lead nuts. I actually build the xy part of it and it was super sturdy and no backlash that I could see.

I just wanted to see what everyone else would make with these parts.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Reply With Quote

Reply With Quote

Bookmarks