Thread: Harrison Mill Conversion

Threaded View

-

08-09-2008 #1

Finally got some photos of the machine that's being converted

No work has been done to the actual machine yet, as I need to keep it as usable as possible, so things will be getting done in stages.

So far I've got the design for the Z-axis ball screw conversion done, which has taken a couple years so far due to other things getting in the way, and me getting frustrated at trying to come up with a workable solution to fit in the available space.

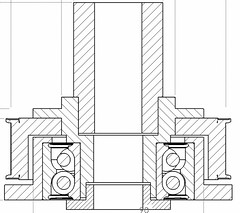

I finally came up with this solution last month -

.

.

I've so far got the bearing housing machined (still needs the bolt mounting holes drilled/countersunk), and am currently waiting for the ballscrew and nut to arrive, so I can get the big chunk of bar in the lathe and machine it in one go.

Progress so far -

The mill doesn't have a Quill, so I'm having to CNC the knee.

Going by my motor power/ballscrew spreadsheet, the stepper alone should be able to move the knee, but it won't leave much power for milling, so I'm going to counterbalance the knee using an air cylinder on each side of the knee. My rough guestimate so far is that two 40mm air cylinders should be adequate, but I'll weigh the table/knee when I get them dismantled for a more accurate weight figure, and then decide on cylinder diameter.

I've also got a collection of bits for the control/drive.

So far I have a 6.5Nm stepper from ArcEuroTrade, a 625VA 55V toroidal, big capacitor, bridge rectifier, a SmoothStepper coupled to a CNC4PC C23 BOB,and as of today a Gecko 203V (and a couple G251 for future use).

Ultimately I'd like to use the planned Gecko Stepper PID (planned for later this year, but more likely sometime next year), hence why I've only bought one G203V. If the PID drives aren't ready in time for when I get round to the x and y, then I'll just buy another couple G203vs.

My aim is to get the Z-axis CNC'd first (it'll at least save me having to crank the knee up/down!), then think about how the other two axis are going to be converted.

At the moment, I've been working on the control box design.

I've so far got a rough layout drawn, and know what heatsinks I'm going to be using, but I still need to get the wiring and smaller components sorted out. At the moment, I've got a few sketches and ideas of possible solutions, but I just need to decide what exactly I'm going to use, and how to fit them together.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

CONVERSION: Sx3 mill conversion

By dazza in forum Conversion Build LogsReplies: 1Last Post: 29-04-2014, 10:23 AM -

NEW MEMBER: Saying hello, about to start a mill conversion.

By irgonomics in forum New Member IntroductionsReplies: 4Last Post: 28-04-2013, 03:35 PM -

CONVERSION: My Sherline Mill Conversion videos

By panofish in forum Conversion Build LogsReplies: 2Last Post: 06-05-2012, 07:13 AM -

Mill conversion to cnc

By wolsey in forum General DiscussionReplies: 1Last Post: 15-08-2011, 11:07 PM -

Help with drill-Mill conversion

By Ross77 in forum Milling Machines, Builds & ConversionsReplies: 134Last Post: 02-04-2010, 10:25 AM

Reply With Quote

Reply With Quote

Bookmarks