Threaded View

-

18-01-2011 #1

Following on from the ideas in 'blackburn mark's thread 'Fingers crossed it'll cut ally' I'm going to document my spindle separately as that thread is getting a bit long...

This is the motor I'm using:

http://www.hobbyking.com/hobbyking/s...idProduct=5142

It will do 6000rpm on 48v, and more power than I'll ever need. I would have bought the 180kv version to get a bit faster if I had not been intending to make an electric bike with it at first!

I've bought an ER16 150mm long 12mm diameter collet chuck along with a set of collets for it which has finally arrived after well over a month. The general idea is to simply replace the existing 12mm shaft with the chuck and put a single double row angular contact bearing at the front for good measure.

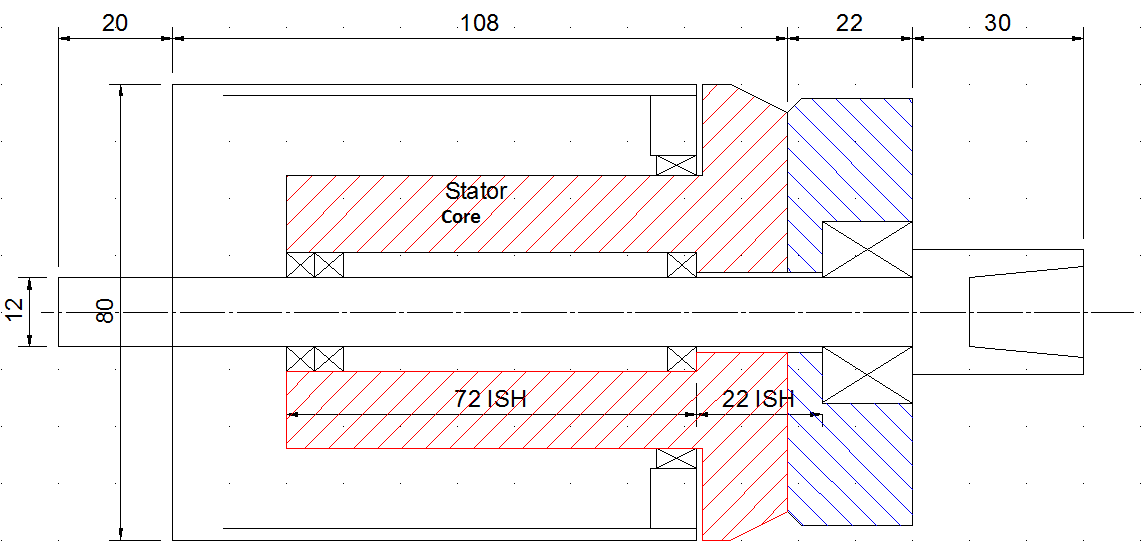

Below is a rough drawing of the motor - I'm not exactly sure of the positions of the bearings inside it. There's three (might be 4) 6801 bearings and one large thin section 6809 (61809 on skf site) bearing near the front of the motor:

(At risk of sounding patronising, remember this is an outrunner motor - so the casing etc rotates.)

I've drawn in the angular contact bearing mounted in a bit of aluminium bar which will bolt nicely onto the existing M5 holes in the motor. The other bearings are left to their own devices.

My problem at this stage is the collet chuck has presumably been ground to 12.000mm, or pretty close so the bearings will just require a press fit. So my problem is how do I fit the shaft through all those little bearings without damaging them. I can't really remove them from the motor since they're stuck in with some sort of adhesive. If all else fails I can remove the part from within the stator that holds those three bearings entirely, and make a new version with better bearings.

The angular contact bearing isn't an issue - I can press that onto the chuck first, then the housing. Should get it nice and accurate...

There's a convinient M8 threaded hole in the end of the collet chuck which I could use along with a thrust bearing to preload the angular contact bearing against the thin section bearing. Having looked at the load ratings for those bearings I think that would be ok. Maybe I should just get another angular contact bearing instead of a thrust bearing, but that would stop me being able to disassemble the thing.

So er...any advice on fittings these bearings or the design would be most welcome! I'll machine it tonight if we come to any reasonable conclusion.Last edited by Jonathan; 18-01-2011 at 05:08 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Diy Brushless Spindle

By blackburn mark in forum Brushless Spindles & MotorsReplies: 181Last Post: 08-06-2021, 03:50 PM -

Spindle motors resonable options

By Web Goblin in forum Spindles & Drive MotorsReplies: 15Last Post: 20-11-2016, 03:31 PM -

DIY Brushless spindle

By booski in forum Brushless Spindles & MotorsReplies: 2Last Post: 30-10-2013, 09:36 AM -

FOR SALE: 400w panasonic ac brushless servo motors and drives

By gavztheouch in forum Items For SaleReplies: 3Last Post: 29-12-2011, 03:04 PM -

FOR SALE: Metabo 710W 230V Electric spindle, stepper motors, Tr nuts 20x4

By Vladimir_MD in forum Items For SaleReplies: 3Last Post: 09-04-2010, 05:24 PM

Reply With Quote

Reply With Quote

Bookmarks