Thread: CNC design for consideration

-

09-04-2012 #1

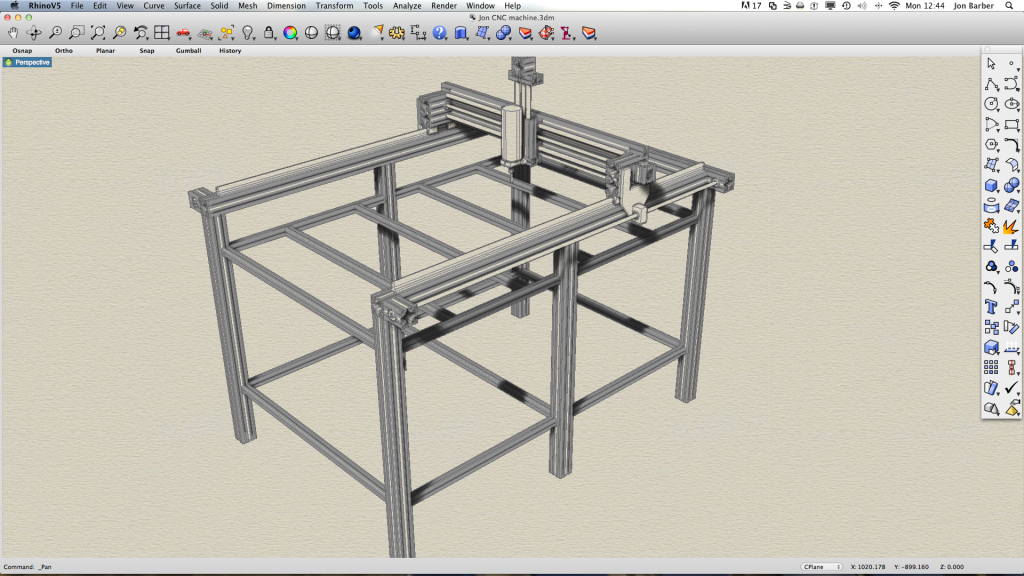

Hi all,

I just wanted maybe a more experienced builder, to have a look at my design and see if there is anything obvious that might hold my design back before I commit. I posted on cnczone and took all comments on a previous design on board and have now come up with this one. Figured it would be more beneficial to be a member of a UK forum. I am already a CNC owner too so not a complete noob, although it would be naive of me to say I'm not still learning.

The goal was to create it as cheap as possible but try and keep rigidity. I've used 12mm multi-start trapezoidal lead screws on x, y and 10mm on z. Fully supported 16mm rails on x and y and 16mm round rail on z. My main concern is the lead screws on y and the 16mm rail. I used that size because it is easier to implement with the size of aluminium profile I'm using. The machine is 1500mm x 1000mm at the rails, ignore the length of z as im going to shorten it anyway. I designed it with a view to implement a fifth axis at a later date. I will be cutting MDF and PLY only.

Any advise would be greatly appreciated. Thanks

-

09-04-2012 #2

Hi Jon,

No problem on the double post's, I have taken care of this for you. Not sure if the link to 1500mm x 1000mm is supposed to be there so I have left it.

Good luck with the build, as noted I would consider going with 20mm rails and if you can Ball screws on each axis. 16mm will work as you know but I would too rather see 20mm rails over a 1500mm length, you could always go to 80x80 profile for the Y axis and this would give you the 40mm centre’s the rail would require for mounting, however 80x80 is not cheap I know so...

Preparation for a 4th axis at this stage would be a good idea, people have been known to bolt a 4th axis to the y table as and when they need it.

Regards,

.Me

-

09-04-2012 #3

Great, I've been looking at ballscrews on zapp and the difference in cost is not really that great. I could easily go with 16mm ballscrews and that just leaves the 16mm-20mm rails on y to sort which shouldn't pose too big a problem. My only question is, can the ballscrews be mounted directly into a flanged bearing with 16mm opening and a shaft coupling at the other end without machining?

-

09-04-2012 #4

most of us buy 1605 screws from china, "linearmotionbearings2008" (ebay) he will machine the ends for you... its worth giving him a shout for a quote

im sure theres a way of mounting without machining, not sure it would be worth the effort though to save £20 ??Last edited by Lee Roberts; 09-04-2012 at 03:51 PM. Reason: added the link for lin2008

-

09-04-2012 #5

That's great thankyou. Agreed for £20 it would be worth getting them machined. I was just referring to zapp who charge £75 for machining. That would add a considerable amount to the build cost.

-

09-04-2012 #6

Yea that guy on ebay is ok to deal with, i got ballscrews off him a few moons ago and they turned up in less then 4 weeks. Didn't know he dose maching now as well, as mark said it would be better to have the ends turned down to what you need rather then go about it the other way.

Here is a few pics to give you some ideas of what you could do.

-

09-04-2012 #7

-

09-04-2012 #8

I normally get a quick order from Chi, 7 to 10 days max but the last half dozen orders have generated a VAT plus handling charge from Fedex, usually about £15, not excessive but worth bearing in mind.

You do have to contact him, tell him just what you want and he'll put that exact order up on Ebay and send you the link. If by some chance someone else buys it before you just tell him and he'll list a duplicate order. The guy is 110% reliable.John S -

-

09-04-2012 #9

Thanks for all your help guys, really appreciate it. Asked for a quote, so just waiting now.

-

10-04-2012 #10

Ok so Chai has replied with a quote. For the 4 rails, 8 blocks, and three machined ball screw assemblies 529usd shipped?!? That seems awfully cheap to me. Does that sound right? I'm about to rip his arm off.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Interesting Papers on heavy duty design, vibrations, composites and column design

By D.C. in forum Gantry/Router Machines & BuildingReplies: 15Last Post: 25-06-2016, 10:13 PM -

Design Help Pt2 Required for CNC design/Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 38Last Post: 21-07-2014, 02:05 PM -

RFQ: Pre-RFQ Design

By Hutchie in forum Projects, Jobs & RequestsReplies: 11Last Post: 05-02-2012, 06:45 PM -

Design help etc required with DIY CNC Router Design / Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 12Last Post: 21-10-2011, 04:50 PM

Reply With Quote

Reply With Quote

Bookmarks