Thread: DIY spindle design

-

31-05-2012 #31

-

31-05-2012 #32

-

31-05-2012 #33

Super video Mark,

-

31-05-2012 #34

-

31-05-2012 #35

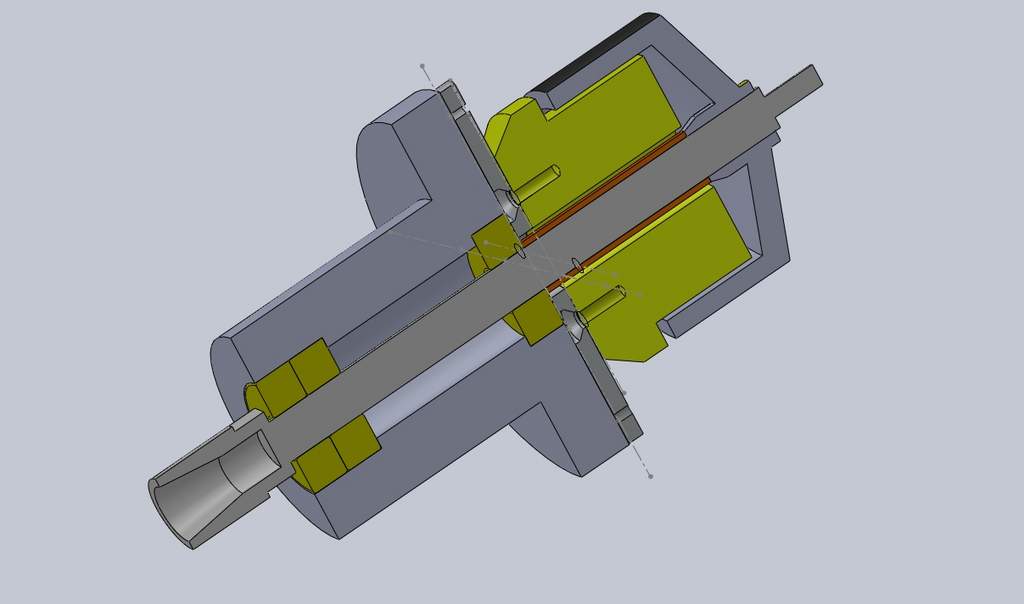

Found this spindle design suitable for smaller cutter sizes, replace the Brushless Motor Shaft with an ER11 spindle which will hold up to 7mm.

http://www.rcgroups.com/forums/showt...1175772&page=5

http://www.giantshark.co.uk/xyh5045-...-p-404603.html

Last edited by ChrisG; 31-05-2012 at 01:32 PM. Reason: Found sa very cheap motor to experiment with.

-

The Following User Says Thank You to ChrisG For This Useful Post:

-

24-06-2012 #36

Have you determined how to pulse the electronic driver for the DC brushless motor?

It should be possible using a 555 timer chip.

SH

-

24-06-2012 #37

-

24-06-2012 #38

Connected to parallel port via PIC development board ... free ish...'acquired' from university.

When I get round to it I'll stick the code on a smaller PIC on a PCB as it's very simple to do and will cost <£1.

-

04-08-2012 #39

You can get 10mm straight shaft ER chucks here.

Results for Tool & Work Holding:ER Collet Chucks

Very cheap tools to be had here.

All (3) the electronic brush-less motor driver testers I have used startup in the midband when first plugged in. I have never found a site or a way to control these things where you can have them start at zero volts and then get ramped up from there using a computer.

Mind you, it's been 4 years since I looked so there may be stuff out there that I don't know about. :-)

It would be good if someone had a way of doing this.

There are sites out there that show you how to make your own outrunner motor but the ones I have found are in German or Swedish and Google translator or babelfish don't do a very good job of converting technical lingo.

You could make your own for whatever revs you need for your power supply. That would be nice for a small machine.

If you do make your own spindles for your outrunner motors then you could use the round tool steel blanks from the same site here.

http://www.ctctools.biz/servlet/the-...D-STEEL/Detail

Lots of different sizes to choose from.

The hardness/brittleness shouldn't be a problem for the power of these small motors.Last edited by baccus61; 04-08-2012 at 04:34 PM.

-

18-08-2012 #40

Hi All

I'm a newbie with a 7x10 lathe that I'm very slowly outfitting and converting to CNC. I am planning on building a tool post spindle to enable me to easily cut key-ways on shafts in my lathe. This thread has been a fantastic eye-opener.

I have purchased a 200KV outrunner motor with an 8mm shaft. It has a power rating of 2450 watts. IS THIS REAL?? At 50% efficiency this would be over 1 HORSEPOWER for a motor that I could hold in my hand.

Indeed if it is real, it is more powerful than the motor which drives my lathe!!

Puzzled,

Art99

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Interesting Papers on heavy duty design, vibrations, composites and column design

By D.C. in forum Gantry/Router Machines & BuildingReplies: 15Last Post: 25-06-2016, 10:13 PM -

Design Help Pt2 Required for CNC design/Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 38Last Post: 21-07-2014, 02:05 PM -

CNC Spindle Repair and Spindle Replacement for any Machine of any Manufacturer

By spindeldoctor in forum Manufacturer NewsReplies: 0Last Post: 13-11-2013, 07:50 PM -

Design help etc required with DIY CNC Router Design / Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 12Last Post: 21-10-2011, 04:50 PM -

My spindle design

By Ross77 in forum Tool & Tooling TechnologyReplies: 22Last Post: 06-08-2010, 06:03 PM

Reply With Quote

Reply With Quote

Bookmarks