-

13-12-2008 #1

Hi all,

Ok, I'm hoping that Gary from Zapp will be able to answer this question......

As part of Zapp's driver kit1 you get a very simple breakout board. I never used it as I had an Optoport from DIYCNC. Now, I'd like to use it to build a control panel with various switches etc. but no matter how hard I try, the only pins I can get to be detected as inputs are pins 10,11,12,13,15. I've set Mach up to use pins 2-9 as input but they are not detected at all. Is there something special I have to do on this board to get the outputs to be inputs?

Regards, Jeff.Nothing is foolproof......to a sufficiently talented fool!

-

14-12-2008 #2

I haven't even used Mach yet, but I have done a little programming with the parallel port and unless anyone feels the need to correct me the, the pins on the parallel port are fixed, i.e. only some are inputs and only some are outputs, and an an input pin cannot become an out and vise versa.

This might be a little of interest...

http://www.codeproject.com/KB/cs/csppleds.aspx

Thats what you were asking right?

Dave.

-

14-12-2008 #3Visit Us: www.automationshop.co.uk

-

14-12-2008 #4

Thanks chaps,

I've worked around it by using some inputs on the Smoothstepper and some on the BOB.

Both Mach and the Smoothstepper have settings to use pins 2-9 as input and you set the PP to bidirectional mode. That way you get a total of 34 inputs from two PP's (42 if you use the Smoothsteppers).

Most probably I need a "smart PP BOB":D

Regards to all and thanks for the help.Nothing is foolproof......to a sufficiently talented fool!

-

14-12-2008 #5

Hi Gary

While you're on the subject of changing things :D

These here ballscrews you do, can you machine the ends to my pattern rather than just cutting your standard ends? Nothing dramatic, just want to hold the screw in tension rather than leave one end floating...

...and, do they come with seals fitted to prevent ingress?...

...and can I specify a non-standard length?...

...and could you fit the nuts for me if I told you which way round they go? I've never actually had a problem fitting ballnuts, I just find it a bit nerve wracking

Much ta

Robin

-

14-12-2008 #6

The simple answer is Yes to all you questions :)

As long as the machining is not something exotic the price will be the same, but bearing in mind most of the machining costs are to do with the fixed end, so if you want machining like the fixed end at both ends i will need to get a quote from the engineering company i use.

If you want a dimension that is in between the 100mm i offer, this is not a problem, infact i do this a lot, you just need to round it up to the nearest 100mm and advise the length, but i will need a proper drawing, with tolerances

Some of the ball nuts come with plastic seals (5mm lead) and the other lead ball nuts come with a rubber seal that is much better.

The reason is that they come from different manufactures.

And fitting the ballnut is not a problem, you would be surprised how many people ask me to do this, and i an thinking of doing this as standard with machined screws.

Visit Us: www.automationshop.co.uk

-

14-12-2008 #7

Sounds promising, I'd probably only need to lengthen the ends a bit, maybe deepen the circlip groove a tadge. A couple of flat spots would be handy.

Can I find the dimensions and details for the double nuts on your website? They seem to be hidden under pre-machined screws, so when you click for info you get told about end machining rather than nuts :confused:

Last time I bought a "zero backlash nut" it was from that other bunch. Turned out I had to crush it sideways. A bit tricky when it's buried under a milling table

-

17-12-2008 #8

THe link to the double ball nuts is here

http://www.slidesandballscrews.com/pdf/35-36.pdf

the ball nuts i have in stock are pre loaded to give a max backlash of 20 micron.

If you want a zero backlash nut, this will need to matched to the ball screw at the factory.

Visit Us: www.automationshop.co.uk

-

17-12-2008 #9Visit Us: www.automationshop.co.uk

-

06-03-2009 #10

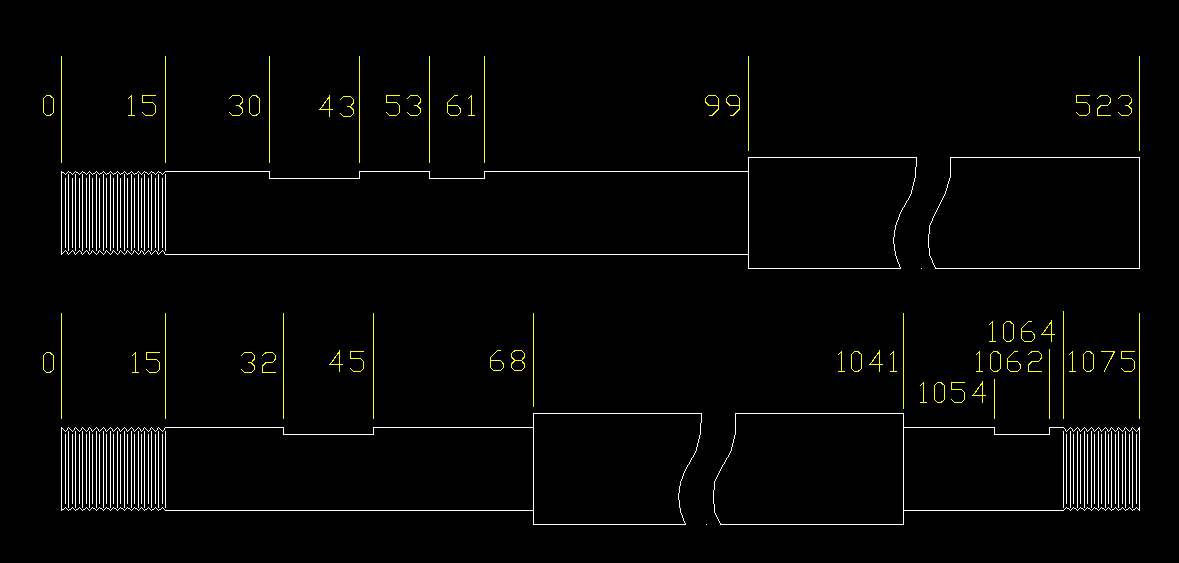

Took a while but here it is, can you make 'em?

16mmx5 screws with your anti backlash double nuts.

Threads are your usual M12x1, flats are 1mm deep.

I'd like 12mm ball races to slide on by hand, not tight. Other tolearances are fairly slack, shall we say .25mm

best regards

Robin

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Congratulations to Gary @ Zapp

By JAZZCNC in forum General DiscussionReplies: 7Last Post: 21-09-2013, 07:44 PM -

Zapp 3-Axis kit - putting it all together

By birchy in forum Motor Drivers & ControllersReplies: 5Last Post: 18-02-2013, 12:05 PM -

10% Discount weekend At Zapp Automation

By Gary in forum Marketplace DiscussionReplies: 10Last Post: 19-02-2012, 12:42 PM -

ZAPP SY60 wiring help

By Smiler in forum Stepper & Servo MotorsReplies: 7Last Post: 07-06-2010, 08:28 PM -

HELP Gary, I'm having a disaster

By Robin Hewitt in forum Linear & Rotary MotionReplies: 3Last Post: 16-04-2009, 10:07 AM

Reply With Quote

Reply With Quote

Bookmarks