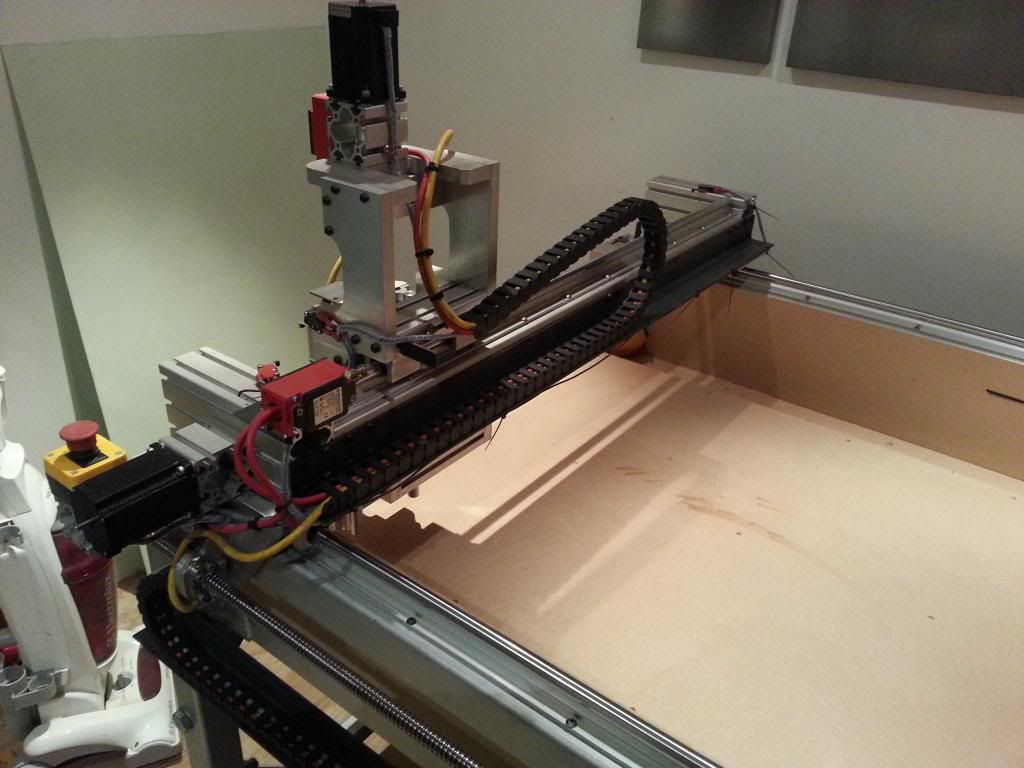

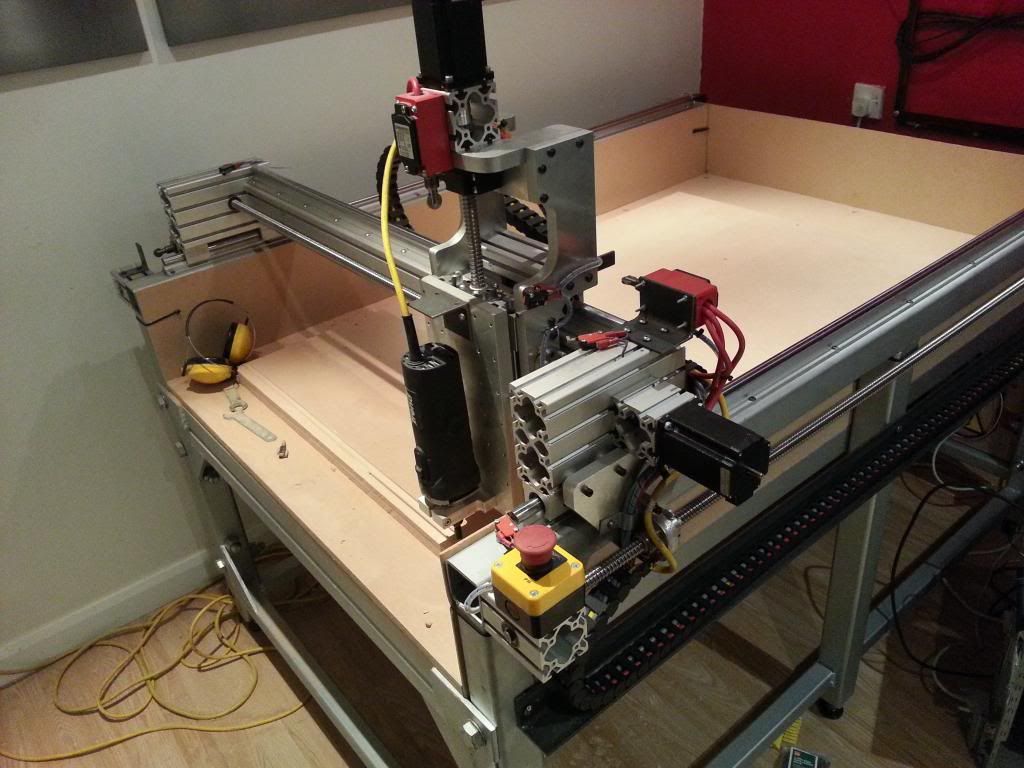

Thread: jon's homemade cnc

-

18-01-2013 #51

i'm glad someone has bumped this, how are you getting on with this fella?

-

19-01-2013 #52

Jon, that machine looks fantastic. In the photo it does not look like the bed framework is connected to the new centre legs, if not would the bed be more stiff if it was bolted to those legs?

Once again, congratulations on what looks like a super build. G.

-

20-01-2013 #53

Jon,

Excellent build! An inspiration for my MkII after I finish Wobbly. Keep it up!

Rgrds

PatrikI've upped my standards. Now, up yours!

-

23-01-2013 #54

Sorry for not posting or replying. I've been dealing with a terminally ill family member so haven't had time for much of anything the last couple months. I actually got the machine finished around the end of November but have yet to cut anything significant on it other than a few signs for work. I started leveling the bed and realized I could really do with a fly cutter as opposed to a quarter inch router bit, and left it at that. I'm totally happy with the speeds and everything though. Hopefully soon i'll have a bit of time to play with it! Think the first thing i'll make will be a touch probe and maybe a belt drive mech for the z axis.

The machine took about 6 months from design to finish and I would estimate a cost of around £1500-£2000(cant remember exactly) - all in. It took that long because I was buying bits every month. If you had all the parts ready I'm sure it could be done a lot quicker. I used Rhinoceros(and Rhinocam) to design it. If you're planning a build, the best advice I would give you is to read, read and read some more. Post your designs, get a second opinion and be prepared for constructive criticism and design changes. Also, make sure you're 100% happy with the design BEFORE buying any parts - will save you money in the long run. Good luck.

-

24-01-2013 #55

thanks for coming back to post given your recent problems dude.

i took a lot of inspiration for my build of the back of this thread and i thank you for that and again thanks for coming back to update.

what is the spindle you are using and any reason why you choose that over a water cooled one?

-

24-01-2013 #56

The spindle was simply a router i had lying around. In all honesty its no good for this, it's only 1kw, but will do until I can afford a water cooled one.

-

06-04-2013 #57

Hi Jon, would you be able to send me some size data on your build. Im new to CNC and I do like the way you have done your cnc.

If you could email me jamie.qld AT gmail.com

Can you also post an update on your build, how is it going, what would you change if you did it again.

Regards

jamieLast edited by jamie aust; 06-04-2013 at 10:40 AM.

-

30-12-2013 #58

Anyone from this "theme" still active? ... I'd like to see any sketches or plans ... if it's possible

-

07-01-2014 #59

realy no one have any information about this machine?

-

07-01-2014 #60

Hi Folc, no i dont think you will find any plans for building this exact machine, however you may find this machine A Sturdy Steel Framed Machine Design to your liking and this dose come with the information your looking for.

.Me.Me

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

FOR SALE: Homemade 'Coventry' Type Easy Change Toolholders

By jamesgates1000 in forum Items For SaleReplies: 8Last Post: 04-12-2015, 09:22 PM -

Homemade 3d laser scanner and free software.. looks really good

By Fivetide in forum Laser Machines & BuildingReplies: 2Last Post: 03-09-2012, 01:09 AM -

Homemade CNC Project Help

By chaslam07 in forum Gantry/Router Machines & BuildingReplies: 1Last Post: 04-04-2012, 11:53 AM -

BUILD LOG: Few pics of my homemade CNC mill

By wiatroda in forum DIY Router Build LogsReplies: 22Last Post: 18-02-2011, 09:43 PM -

Homemade desktop CNC - cutting 0.8mm mild steel out the question?

By HankMcSpank in forum General DiscussionReplies: 7Last Post: 16-04-2010, 09:37 AM

Reply With Quote

Reply With Quote

Bookmarks