Thread: Machine Problem - Rockcliff

-

16-02-2009 #11

Sure would love to help Lee but I have still to cross that bridge when my homebrew gets done. I will certainly be holding my breath when it finally gets going as I can assure you that something somewhere will rear its ugly head........ hope it all gets sorted bro

-

16-02-2009 #12

kammo,

If you get stuck, give us a shout, I'm only just round the corner.

John S.

-

16-02-2009 #13

I had a similar problem. 1mm in the y and 2mm in the x. Problem was circles were round but only 1mm shorter than specified.

used mach 3s auto setup. The one where it asks you to go a certain distance and then you measure it. Seems to have worked.

Initially i thought it was backlash but when I changed this it made it worse.

Im using a 8mm threaded rod on all axis and worked out it should be 320 steps per mm. With the mach setup it said I needed 326.xxx on one axis and something similar on the other.

Maybe the threaded rod wasnt exactly 1.25mm.

Anyway problem sorted.

-

16-02-2009 #14

Hi John, many thanks I will certainly need all the help I can get as I near the completion of my build. How are you ? I saw Adam 4-5weeks ago in Long Eaton and tried to attract his attention but I was on the other side of the road and I didn't want to shout out loud as it was real busy but just wanted to say that I hadn't forgot about giving you a call on my build just been real busy as little un gets all the attention now, keeps us on our toes. I still have your number and would love to meet up with you again as you are certainly a very skillfull knowledgeable gentleman as last time I saw you I thought how great it was talking with someone who knows what he is talking about and if there is anybody I would like to learn from and thats you. I am off work from Wednesday till the following Monday as kids are off school and such and maybe if you are not busy which I'm sure you are I'd like to show you what I've done and have a good chat with what might need to be done next, hope this is ok let me know. Again John many,many thanks for all the help you gave me last time it was a real pleasure "CHEERS!" Laz aka Kammo1

-

17-02-2009 #15

Hi guys, i will be posting back to you all soon i'm just going over a few things this end first based on what some of you have suggested. The problem was somthing i said i had checked but didnt check properly !

What screen is this on please mate, i'm close but not close enuff and i think this could be the iceing on the cake if i could find the damn thing..Me

-

17-02-2009 #16

Just a quick update:

I just found the "auto setup" thing i asked for above, its under the "Setting Alt6" tab, then look to the bottom left just above the big red "Reset" button. I will post back later today as per my above post..Me

-

18-02-2009 #17

Firstly Thanks and apologies to you all…

Here’s why…

I said I had Checked Calibration and the machine moves 20mm physically when moved/jogged 20mm on the screen for mach3. Ok well that was true however only to my steel ruler and in a rushing over enthusiastic way.

I also said I had checked my Tool settings in my drawing, well that is true also but I hadn’t set the Stepdown/pass’s correctly and the two 5mm pass’s used to cut the part in my first post was basically me pushing a weak machine to fast and to hard perhaps?

So I read over what you have all been posting and sending me via email, along the way I picked up a few things I really needed to look at properly, mainly calibration and backlash.

In all the excitement to getting my machine “up and running” these are both things I didn’t really give much attention to and for that I’m sorry for taking up everyone’s time but in away everyone helped because it made me step back and take a proper look at everything.

It didn’t help that my digital calliper went flat on me last week (the battery!), what I have now basically done is run calibration tests on each axis, it turns out the machine was out in all 3 axis’s .

.

So I got everything down on paper, when I run the Axis Calibration it kept setting up my Y axis to some really odd settings I don’t know why because the X and Z it didn’t seem to have a problem with as they both got the same settings assigned to them from mach, then I read up about how to adjust for backlash and then proceed to setup mach to account for the backlash on all 3 axis's.

My calliper is only a cheap one so working in mm I have only got 0.0 on the actual readout display of the calliper, anyway I did the above and I now seem to be spot on in all 3 axis’s, I went 100mm on all 3 axis’s however I only did this in 1 direction on each, dose that matter? I know you said to go to atleast 200-250mm but my calliper will only goto 155mm .

.

Once I was happy that I wasn’t going to get it much better, I drew out (using a marker) a number of different size boxes, I then checked they were to the right sizes and square.

Once I did that I then tried cutting the part in my first post again, only this time I only stepped down on each pass 1mm at a time and I just made 2-3 passes.

When I checked the sizes of the part I was still out 1mm here, ½ a millimetre there and it wasn’t quite right. I then went back to the forums and read some of your new posts, the one by AlexBanich who said:

I'm wondering if you’re not losing position under load like captain resonator has mentioned. You would think though if that were the situation though you'd not have a uniform error.

Well I then pulled out one of the very first drawings I did on a bit of chipboard, I looked at the sizes and to my surprise they were quite close (if only I had calliper, when I drew it out!).

I then started to question if I was losing position under cutting load. So I put it to the test but this time I only did ½ a millimetre pass’s.

While there was room for improvement it was the best it had been so far!

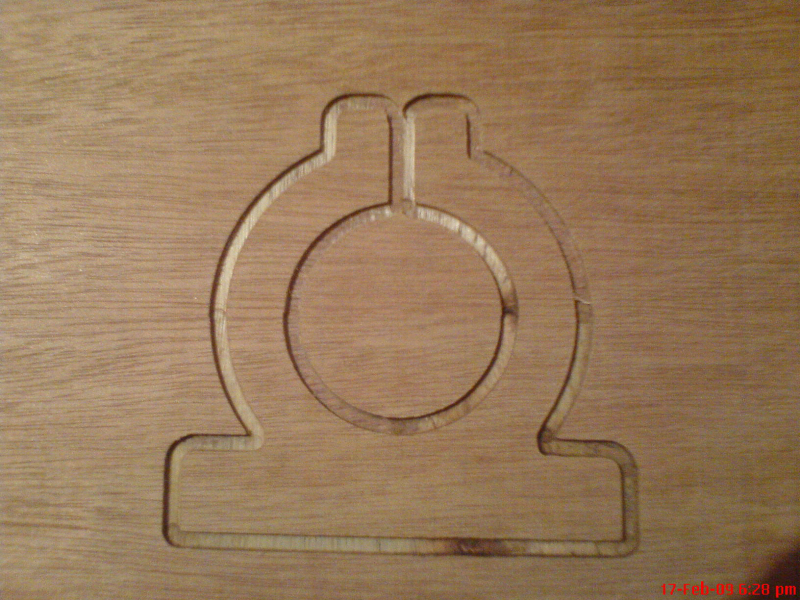

So, I then did it again, this time I tweaked my spindle speed so that I wasn’t getting any smoke from the cutter but the speed was enough that everything was still running/cutting smoothly. In the picture below you can see what the result was:

all checks done on sizes and we have a WINNER!, fair enough my calliper is only cheap so I can’t really say its spot on.

So to sum up:

I wasn’t accurate enough in my so called original “calibration”.

I learnt that the Steps per settings need to be calculated properly.

That Backlash compensation is your friend when you want to start really fine tuning the calibration, so use it Lee!

The other thing that I have also discovered is that quite frankly my Rockcliff is really sensitive when under load, if I try to make passes above ½ a millimetre; the results are no good/wrong.

I used 12 1/2mm round rail and mdf for the build and because of this the machine is weak? Fragile? I don’t know what the best description is.

So ill do some more cutting and work out what is best or what my sweet spot is so to speak but it’s not going to be great in terms of how fast I can machine parts but I’ve walked away with some more knowledge and better understanding of what I’m dealing with so I guess that’s great.

I think there is a few other things I can do to help give the machine a fighting chance, the cutter I have been using is a 3mm, 3 Flute End Mill it cost about £1 from Hong Kong and it now looks like it’s been thro the war.

I’ve got myself some dormer ends mills and I’m thinking about coming down in cutter diameter to see if that helps at all. So time will tell!

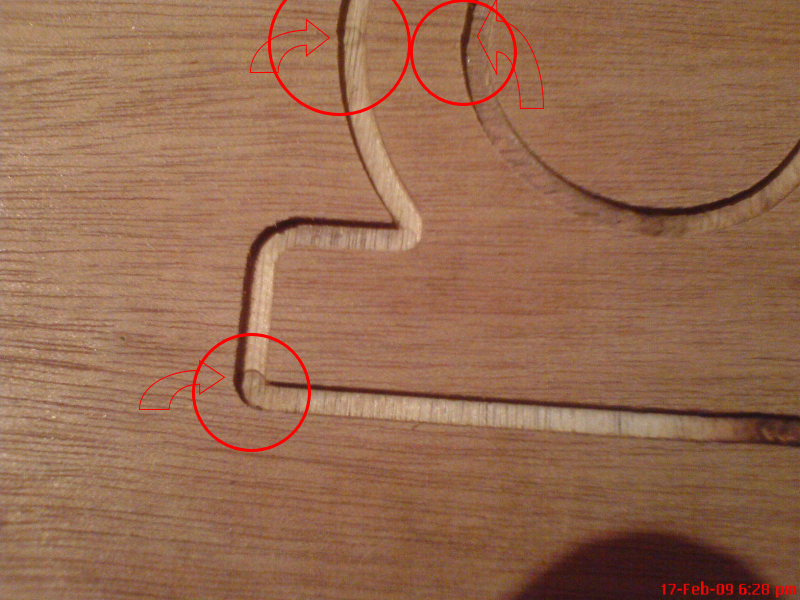

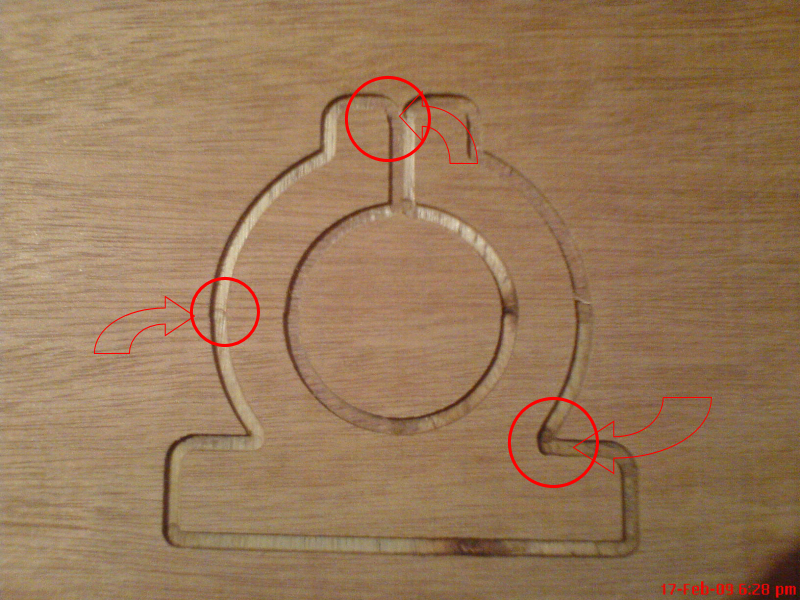

The problem I seem to have now is, when the machine is running it seems to cut about 35mm then pause's for a second, then starts off again.

It dose another 35mm, then another pause, and it does this until the job done. Is this right?

It only seems to have started doing it since I setup backlash adjustment on mach. I wouldn’t mind but when it starts to take off again its actually that sensitive the cutter is moving off line as it starts to cut into the material again, this is now also giving a discrepancy In the cut part, hopefully you can see what I mean in the pick below:

I will update again later tonight with a video of the machine cutting so you can see what is going on.

Again, Thanks for all your input guys your suggestions all helped me along the way to finding the “answers” and for that I’m very much grateful.

Ok its now gone 2:30am and its time for bed, catch up with you all later.

Cheers,.Me

-

18-02-2009 #18

Lee,

The discrepancy and the pauses will be the backlash compensation. On a change of direction of an axis, Mach pauses the cut while the backlash is taken out. I am sure there is somewhere within Mach that lets you change the speed of the update but I'm not sure where it is as I do not need backlash comp on my machine - apologies, I don't mean to gloat :)

Mike

-

18-02-2009 #19What are you using for the spindle motor? If you intend to use anything heavier than a Dremel, then you really need to consider using larger diameter rails. The flexing in a 1/2" (12.7mm) rail is too great for anything other than cutting polystyrene; seriously. Nick at RockCliff stresses that in his forums that his initial designs used 1/2" and he has since up graded to 5/8" or 16mm. It is amazing how much more rigidity that extra 3mm provides.I used 12 1/2mm round rail and mdf for the build and because of this the machine is weak? Fragile? I don’t know what the best description is.

As for MDF -- if you used the 19mm as spec'ed, you will have ample strength for cutting even light gauge metal sheet.

I have been using a B&Q 1020W £20 router with a modified base -- it is heavy at 2kg, and with the Z motor at 1.85 Nm I can't drive it quicker than 300 mm/min or it stalls out. I'm using motor driver modules from http://www.jafmotion.co.uk/motordrives.htm that I think need to be used with caution.

The other thing to ask is do you need backlash compensation?

To prove it maybe cut a square with your 3mm cutter and repeat it many times. If the track is still only 3mm after 10 or 15 repeats, then you do not need backlash compensation.

I need to get a new X/Z interface plate made in Al with bearing blocks in Al that won't shake loose in time.

My machine was built using 19mm MDF as per the plans; 16mm and 5/8" guide rails (redeemed from plotters and ebay), and Oil-Lite sleeve bearings; Lead screw 10 x 1.5 mm standard threaded bar from B&Q. FL57STH76-2808B motors from http://www.motioncontrolproducts.com/nema23.html.

cheersTemplecorran

Where the Light was kept during the Dark Ages

-

18-02-2009 #20

Are you cutting uphill or downhill? If you cut it oversize to remove the excess then finish cut downhill, tool flex ceases to be an undersize problem because it shies away from the job. May need a second pass at finished size to clear any excess

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Boxford 125 TCL Searching for machine problem

By dragon in forum Boxford LathesReplies: 1Last Post: 28-12-2014, 09:27 PM -

Location of machine problem

By Eugene in forum Computer SoftwareReplies: 2Last Post: 27-01-2011, 07:00 AM -

Machine problem. Heiz. Blew up on me !

By xchipx in forum Heiz CNC RoutersReplies: 2Last Post: 03-04-2009, 01:08 PM -

Machine problem with softlimits mach3 & Estop

By Steve-m in forum Artsoft Mach (3 & 4)Replies: 9Last Post: 12-01-2009, 05:38 PM -

NEW MEMBER: Rockcliff

By Rockcliff in forum New Member IntroductionsReplies: 3Last Post: 05-08-2007, 02:32 AM

Reply With Quote

Reply With Quote

Bookmarks