Thread: edge finish - ripples and ridges

Threaded View

-

06-07-2013 #1

Hi everyone,

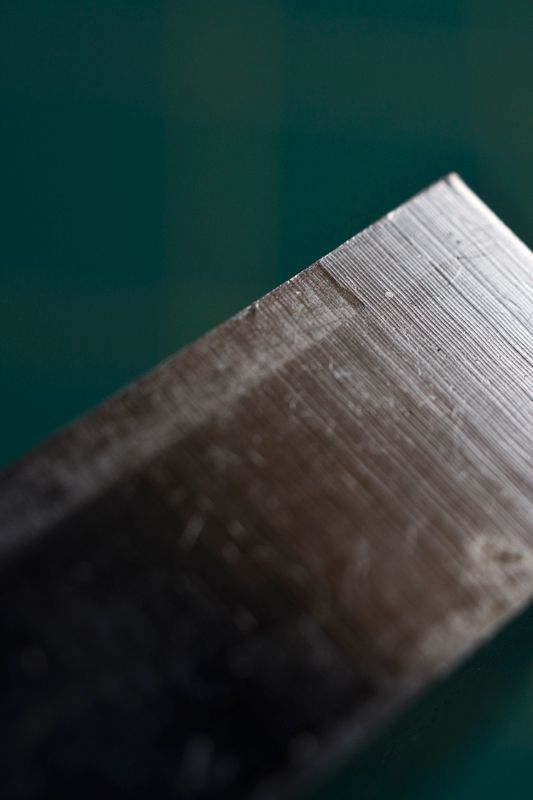

got some parts cut by a friend of a friend, as it's a favor I don't want to start moaning, but I've noticed a few strange things on the edge finish (cut is done in 15mm ali):

1. ripples - is this simply a cut done too fast?

2. seems like the cut was done it two steps, really deep (around 12mm) and finishing cut to go all the way through (the remaining 3mm).

3. the beginning of the cut seems like 'single', but a few mm later transitions to a two step cut. Am I correct to think that it was started as a single, full depth cut, but due to this being too much for the machine, it was split and done in to cuts instead?

The ripples I can live with, it's only really on a single element, but the two-step cut causes problems as it creates a ridge in the lower part of the edge, which means that instead of nice flat edge surface, I end up with something a bit wonky.

Cheers for any pointers or additional info.

Regards,

dsc.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

How to get this finish..?

By Wal in forum Metal Finishing TechniquesReplies: 15Last Post: 02-02-2017, 11:08 PM -

Ridges in 3D profiles = hair loss and lots sandpaper

By Shinobiwan in forum Machine DiscussionReplies: 9Last Post: 11-04-2013, 07:45 PM -

Can you identify this paint on metal finish..?

By Wal in forum Metalwork DiscussionReplies: 2Last Post: 29-01-2013, 06:25 PM -

Better finish

By luke11cnc in forum Wood Finishing Tips & TricksReplies: 20Last Post: 27-03-2012, 11:25 PM -

Need advice on surface finish

By FatFreddie in forum Machine DiscussionReplies: 4Last Post: 01-05-2010, 02:51 PM

Reply With Quote

Reply With Quote

Bookmarks