Threaded View

-

05-03-2014 #1

Hi all,

Consider this my introduction, im Phil, from Kent uk and have a cabinetry workshop producing all kinds of cabinets. I was looking to buy a second hand CNC router but decided i wanted to be the service provider for my own machine, not sub contracting servicing to a manufacturer.

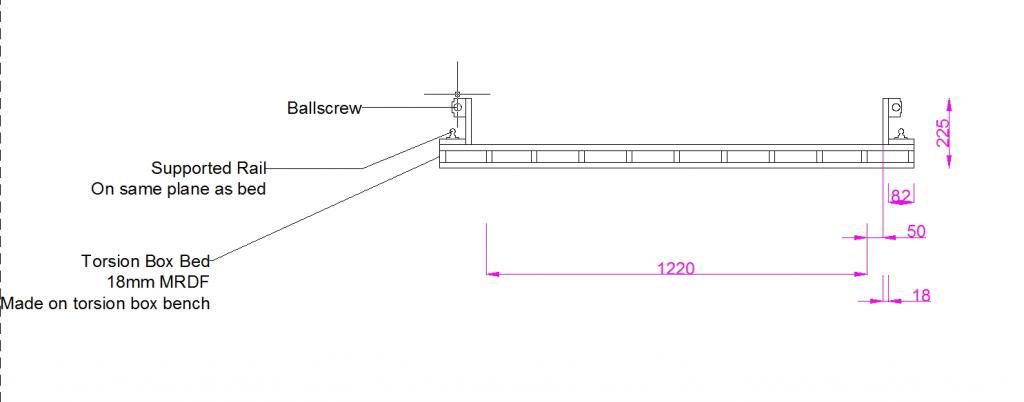

Anyway, i want to build a gantry machine, it will be MDF torsion box based bed as i know i can build one dead flat. I have the design of the actual build nearly done, just working on getiing my head around the electrics, method of moving the axis about, and understanding how all of that works.

I want to build a machine that can take half standard sheets, so 1220 x 1220 in all, i was up for producing a full size machine, but not 100% sure if it is the right thing to do, obviously that would be my ideal, but the thought of a full 2440x1220 working area seems as though i would encounter issues with tolerances etc, however, if it is what i would ideally like, might i not as well go for it?

Here's the design, bit different to everyone elses drawings, i am a 2d CAD man, so bear with me. It is not complete, and i am just understanding the rail types etc so not got much further than that yet.

Ok this is the basic end view of the bed, comments welcome, but bear in mind, i am not familiar with all of the lingo so treat me like an idiot.

the support under the bed is likely to be light construction steel/alu framework as the bed will be very rigid in itself, basically zero flex/sway leg structure to support the loads above, lots of diagonals, lots of solid joints, nice and level, with levelling feet

this really is the first draft, but i need help, and there is no place better than here right?

will be running steppers, not sure on how to do drivers, controllers etc, my friend suggested to ask if i could use RPI (raspberry p i ) i dont know how but it is a great system/component from what i hear.

Also with regard to actually drawing designs to cut, i use CAD currently (drawing above is just a quick draft) is there a way to use CAD drawings/dwg files with a cnc through the other programs like MACH3 and Linux CNC?

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

NEW MEMBER: What to buy when starting out

By smith99 in forum New Member IntroductionsReplies: 18Last Post: 11-04-2014, 01:13 AM -

BUILD LOG: starting from scratch- router 1st project

By idefix in forum DIY Router Build LogsReplies: 24Last Post: 10-01-2014, 12:53 AM -

NEW MEMBER: Complete beginener starting to learn

By johnd in forum New Member IntroductionsReplies: 1Last Post: 05-04-2013, 11:10 PM -

Need advice on starting my own machine shop.

By newtoid1986 in forum General DiscussionReplies: 16Last Post: 04-10-2011, 10:35 PM -

BUILD LOG: new build just starting

By dickieto in forum DIY Router Build LogsReplies: 5Last Post: 26-12-2009, 02:49 AM

Reply With Quote

Reply With Quote

Bookmarks