Thread: Hybrid Mill Design

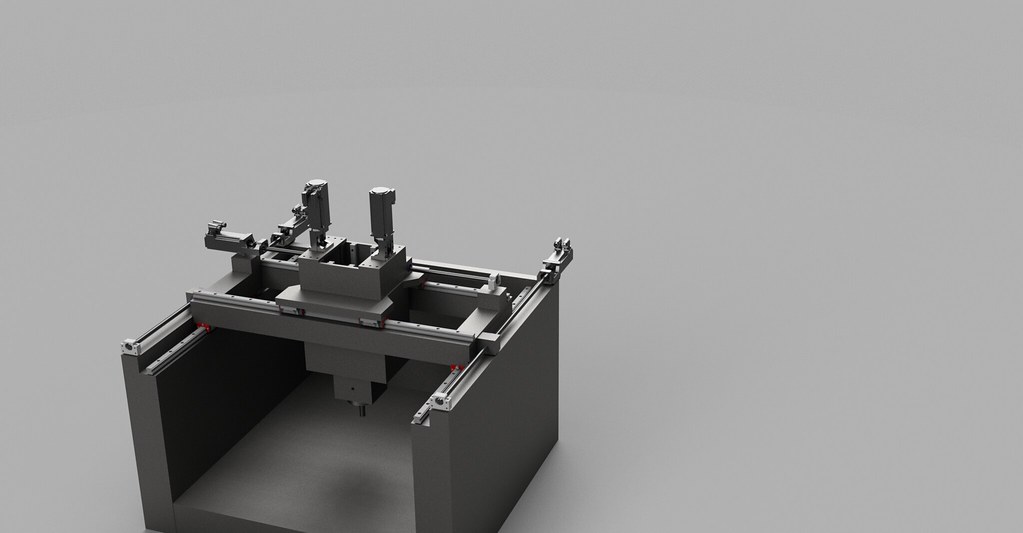

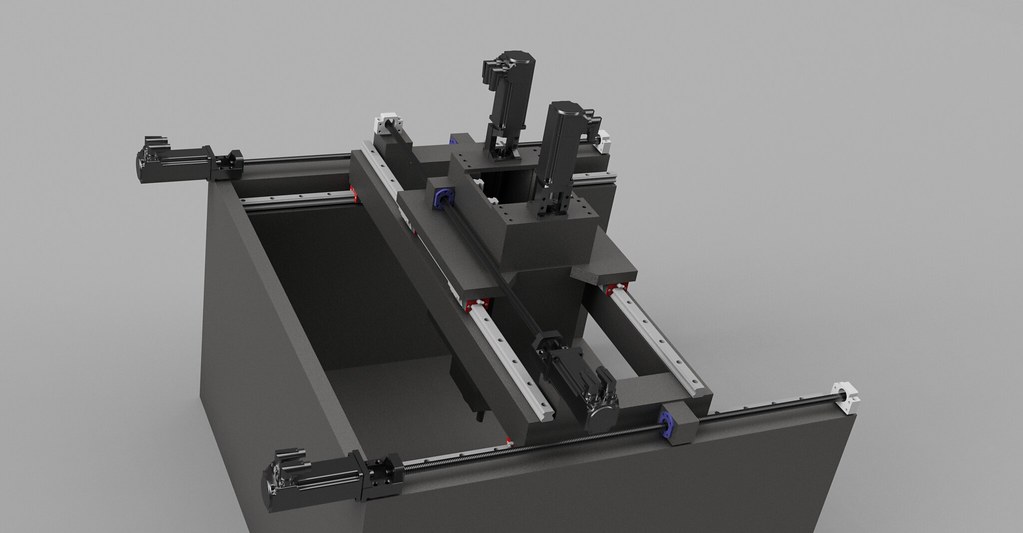

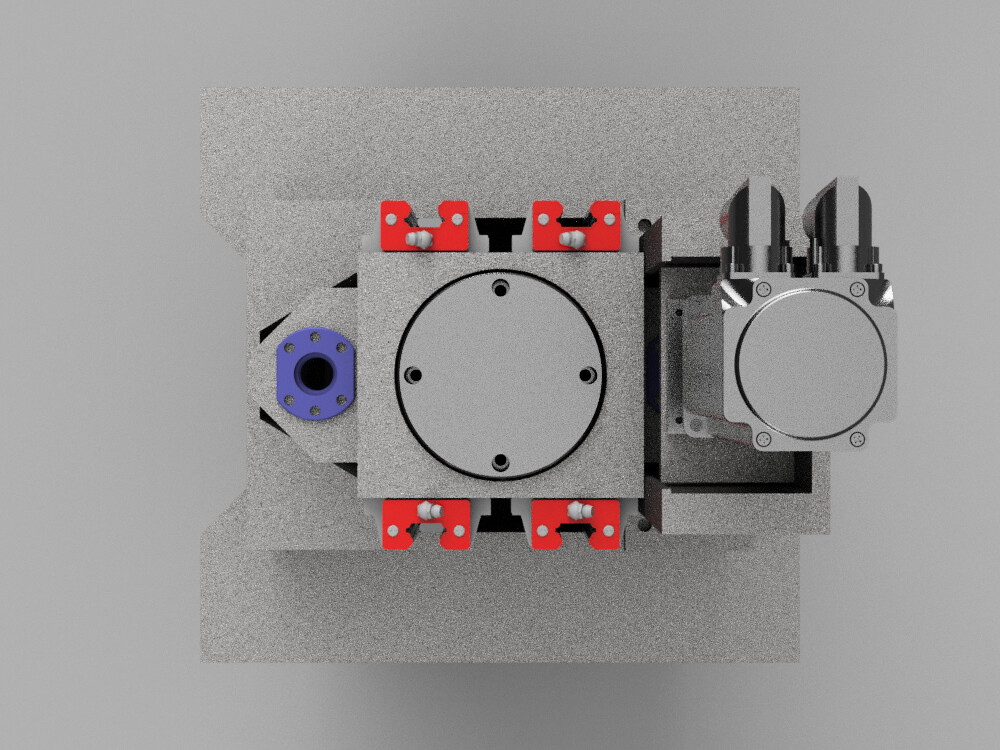

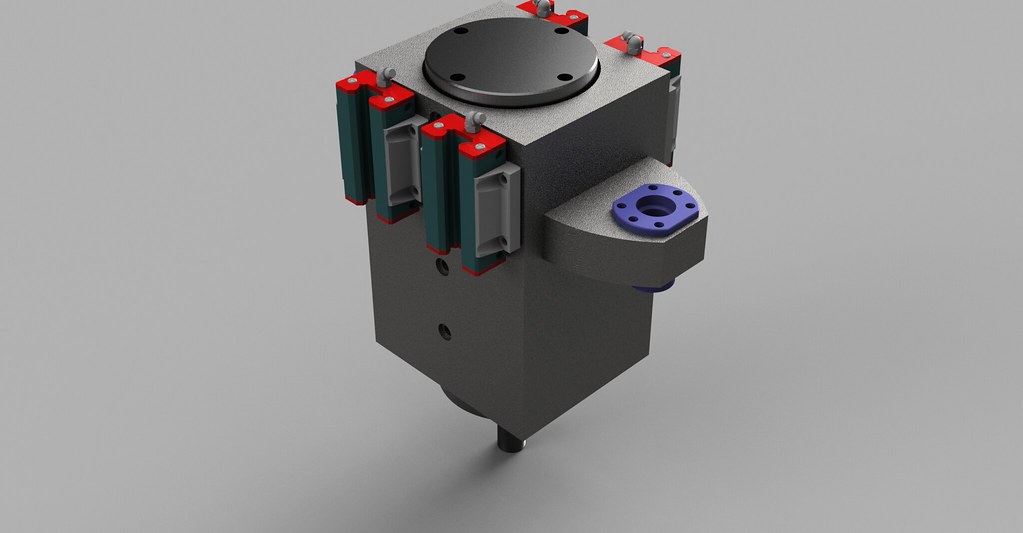

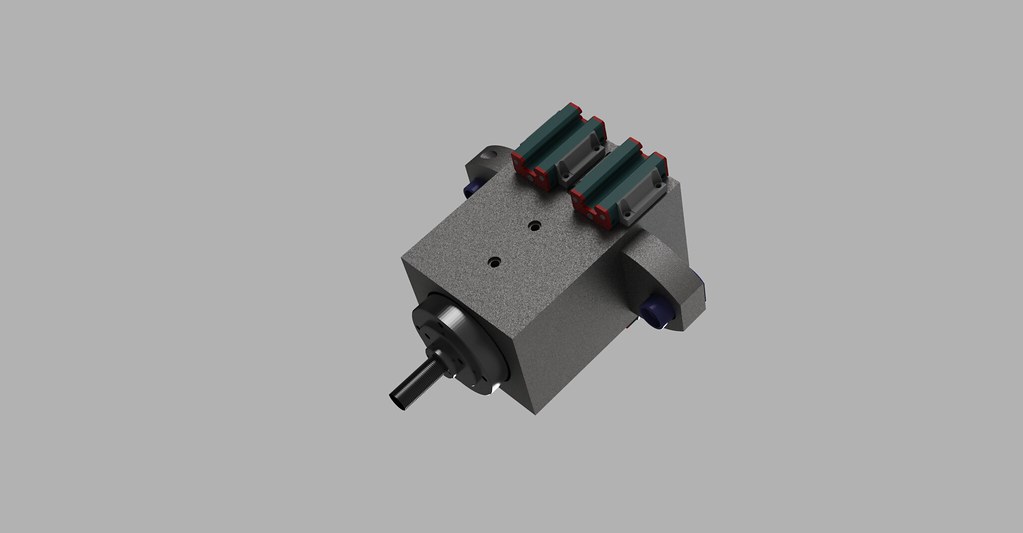

Hybrid View

-

29-11-2015 #1

Hi,

So I would like to get a larger mill that is designed mainly for cutting Aluminium. This means high speed spindle and fairly quick feed rates.

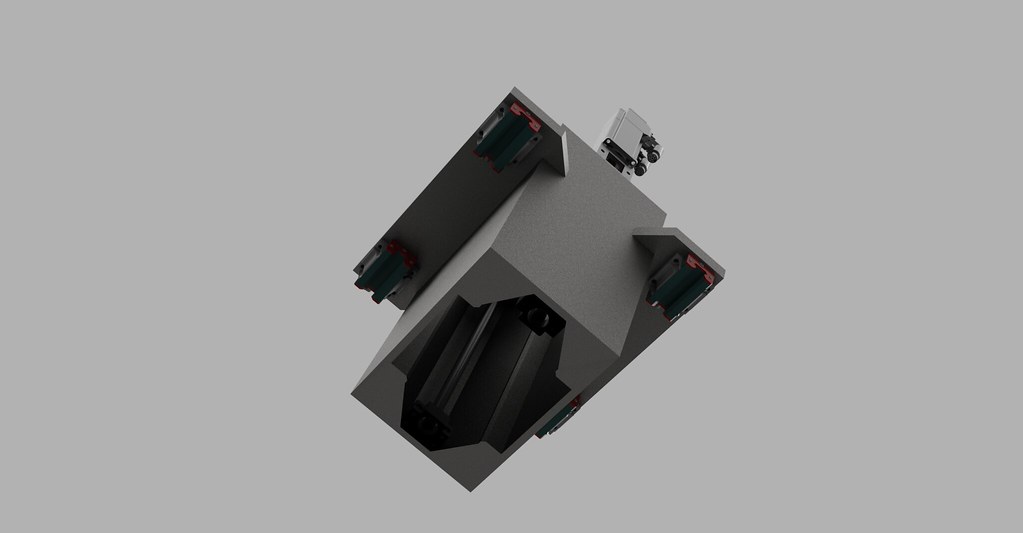

Heavily inspired by this design (http://uk.dmgmori.com/blob/172034/d7...0-pdf-data.pdf), see pages 4 to 7, I came up with the following design. This is also very similar to the Ultimaker 3D printer design where you have a 'box' and you keep all the movement on top and place everything centrally over the table.

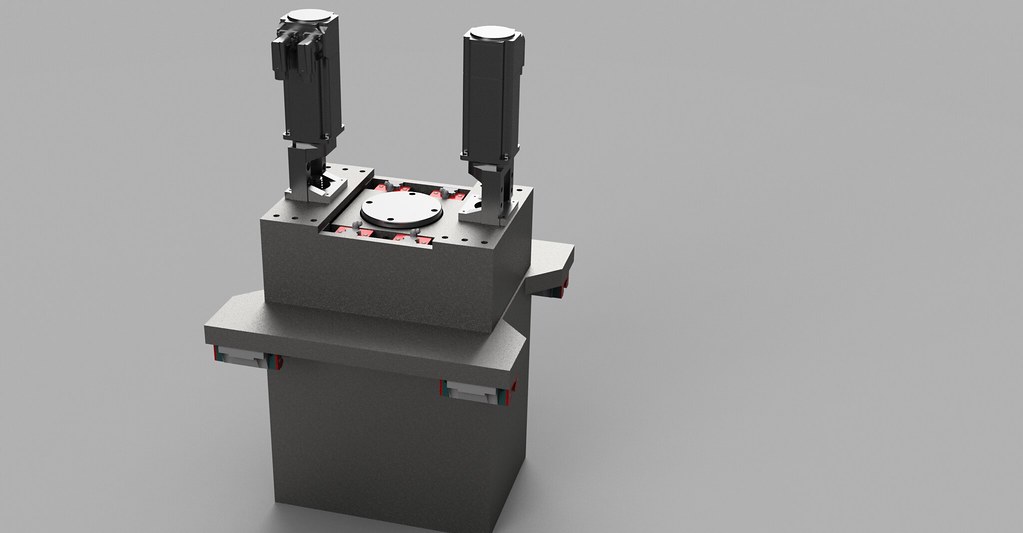

The design is drawn using 1605 Leadscrews (C5 grade) and 400W Servo Motors (4, 5 or 6) - Cant decide if Z and Y need 2nd screws or not. Rails are Hiwin 20 (for Z) and 25 for X and Y.

The spindle will be a 4KW Chinese Watercooled spindle.

Cutting size based on the design is around X and Y - 600 mm x 600 mm x 250 mm.

For the frame, I want to look at using something 'interesting' like Epoxy Granite or something similar. For any parts that are needed, these will be done out of either steel or aluminium.

Thoughts / critique welcome. Thanks.

Last edited by Chaz; 29-11-2015 at 05:06 PM.

-

29-11-2015 #2

Chaz - can't help with any of your questions but I've seen that you are using Fusion 360 for this design. I'm using the same thing (and gradually getting to grips with it) although I haven't looked at any fancy renderings yet! However, can you give a pointer to a source of the Hiwin carriages and rails? Are these from Hiwin, and what drawing format works for you?

Thanks,

-

29-11-2015 #3

Hi, how did you know it was Fusion? Hehe.

There is a place that I found the CAD documents on .... I import them as STEP file IIRC.

http://hiwin.partcommunity.com/ - you need to register, quick and easy.

-

29-11-2015 #4

Because you mentioned it in another post! I thought the question fitted better here, though. Many thanks for the answer - I'll go take a look.

I have to say that things like F360 make 3D CAD much more accessible even to a novice amateur like me, and your pictures above are a great demonstration of what can be done.

-

29-11-2015 #5

I have just been watching a video here https://www.youtube.com/watch?v=o-GBpUZ3piY If you have used SW it seems very easy to use. I am impressed and will give it a try.

..Clive

The more you know, The better you know, How little you know

-

29-11-2015 #6

Any comments on my mill design ;p ?

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Hybrid Stepper Servo

By Boyan Silyavski in forum Motor Drivers & ControllersReplies: 0Last Post: 08-06-2015, 12:41 PM -

Interesting Mill Design on Hackaday

By epninety in forum Milling Machines, Builds & ConversionsReplies: 4Last Post: 01-03-2014, 05:10 PM -

Building a hybrid CNC mill. Need advice and recommendations

By oldmam4m80s in forum Milling Machines, Builds & ConversionsReplies: 8Last Post: 16-08-2013, 07:11 AM -

Hybrid gantry

By routercnc in forum Gantry/Router Machines & BuildingReplies: 5Last Post: 17-04-2012, 08:09 PM -

Small Mill very early design stage

By leadinglights in forum Milling Machines, Builds & ConversionsReplies: 29Last Post: 15-06-2010, 01:05 AM

Reply With Quote

Reply With Quote

Bookmarks