Thread: Thor, or should that be Zeus?

-

29-12-2016 #161

-

29-12-2016 #162

-

29-12-2016 #163

-

30-12-2016 #164

-

The Following User Says Thank You to Tom J For This Useful Post:

-

08-01-2017 #165

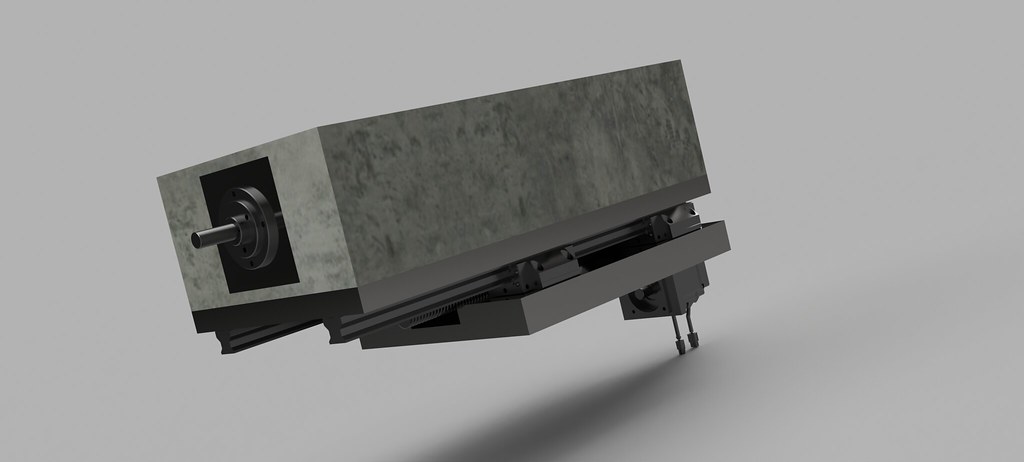

So, keen to get some feedback on the Z Axis.

Nothing too controversial except for the use of concrete. The concrete will be formed around the spindle with a few mm spare and then once the concrete is set, the spindle will be installed via a plate at the bottom and then DWH forming epoxy (the liquid version of the stuff I used for the rails) will be cast around the spindle. This means that the spindle (it needs to be planned so it can be removed from the bottom) will be a 'press fit' into the concrete. The aim of this is to both strengthen the Axis (Axial and Radial) however absorb vibration and improve the Z Axis overall.

The concrete will be around 39 litres which makes up a weight of around 90 kg.

Thoughts / comments / concerns?

-

08-01-2017 #166

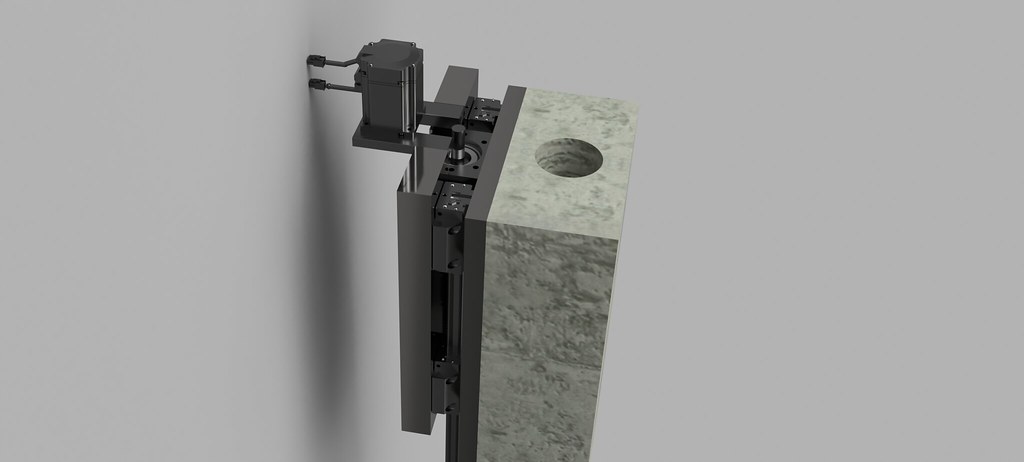

I need to improve the area around where the pulleys will go to create more space.

Also, any view on how well UHPC will 'stick' to Alu compared to Mild Steel? I need to finalise the material selection for the main plate.

-

08-01-2017 #167

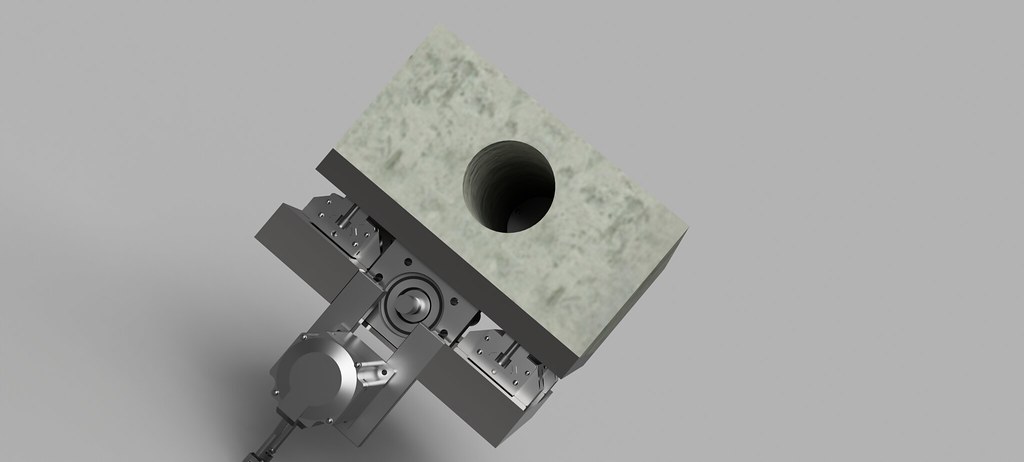

Not sure if this helps show the details in and under the concrete?

-

08-01-2017 #168

Think I'd be more inclined to have sleeve machined for the Spindle then set this in concrete. Don't think you'll get the strength/accuracy required from casting alone and will be bitch to remove spindle.

-

08-01-2017 #169

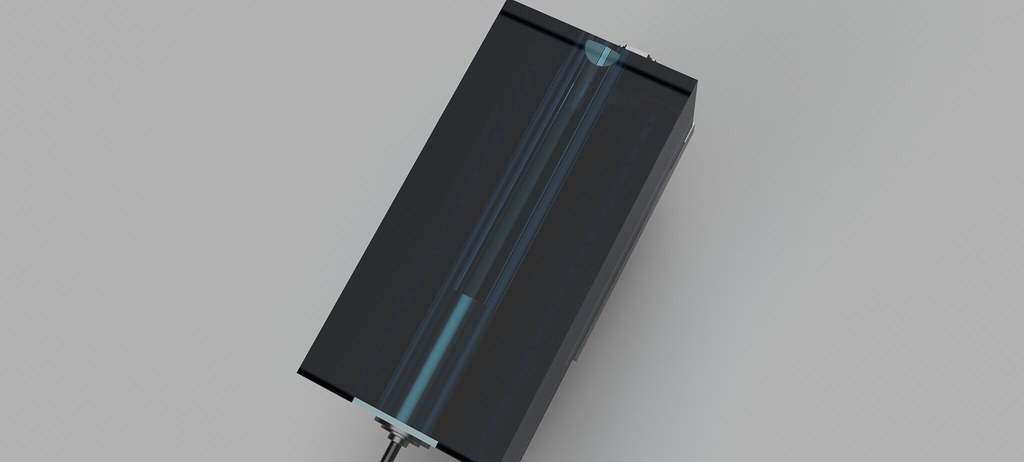

With the DWH epoxy, it will follow the shape down to the micron. That is one of the uses of the epoxy and it doesnt shrink. Removing it, well, agreed, that might be interesting.

The Concrete with a tight fit epoxy will provide a lot of strength and vibration damping. I need to check however, on the 4KW spindles, the pictures show that there are no 'lips' on any of the structure, so it can be removed once cast (lets assume its greased or similar). If it has a diameter larger anywhere, this will be the minimum I can do which means that the concrete is just there to provide overall damping and strength to the plate.

An idea that was provided was to cast the hole to the smallest possible. If I wanted to use a BT30 setup (I have one drawn), having a few mm spaced on the sides is not a major problem, just dont get the full benefit of the concrete.

For me, I love the idea of BT30, I already have tools for this however Id like something that can do at minimum 12K too, so might go with a dual approach on this one.

-

08-01-2017 #170

Yes Know about the accuracy of The DWH Epoxy but still think will cause trouble and then if you talking Chinese type spindles like 2.2kw how would you clamp it or stop it from sliding etc. Would need plates making or some form of fixture.?

Think I'd be going with more conventional Cartridge spindle into sleeve set in concrete. This will give more options for replacement etc. ie 40 taper

Also why not BT30 for 12K can get them with bearings rated at those speeds and plenty of holders that are balanced for higher speeds.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Reply With Quote

Reply With Quote

Bookmarks