Thread: Thor, or should that be Zeus?

Hybrid View

-

12-08-2017 #1

Two of these, almost a year ago, lol.

https://www.machsupport.com/forum/in...ic,5004.0.html

-

29-08-2017 #2

So Ive bit the bullet and bought a 'proper' probe. Its mechanical, not electrical and I want to make an arm for it like the Datron has that comes down, probes and I can then move it back in the 'up' position when not needed. Thinking to use some form of offsets to make this work.

How do I manage with an arm to rotate 180 degrees? Arduino Uno and servo? Id need a fairly strong servo me thinks ....

Thoughts?

-

29-08-2017 #3

Do you think it is possible to rotate about a hole/pin and get the repeatability ? How about sliding the arm up and down with a piece of spring steel to hold it against a ground edge? Could have a slot in the middle with a fixed dowel pin to give top and bottom end stops. Then add detents for top and bottom position. Manually move it up and down as required or drive it via a motor with a cam?

-

29-08-2017 #4

-

11-10-2017 #5

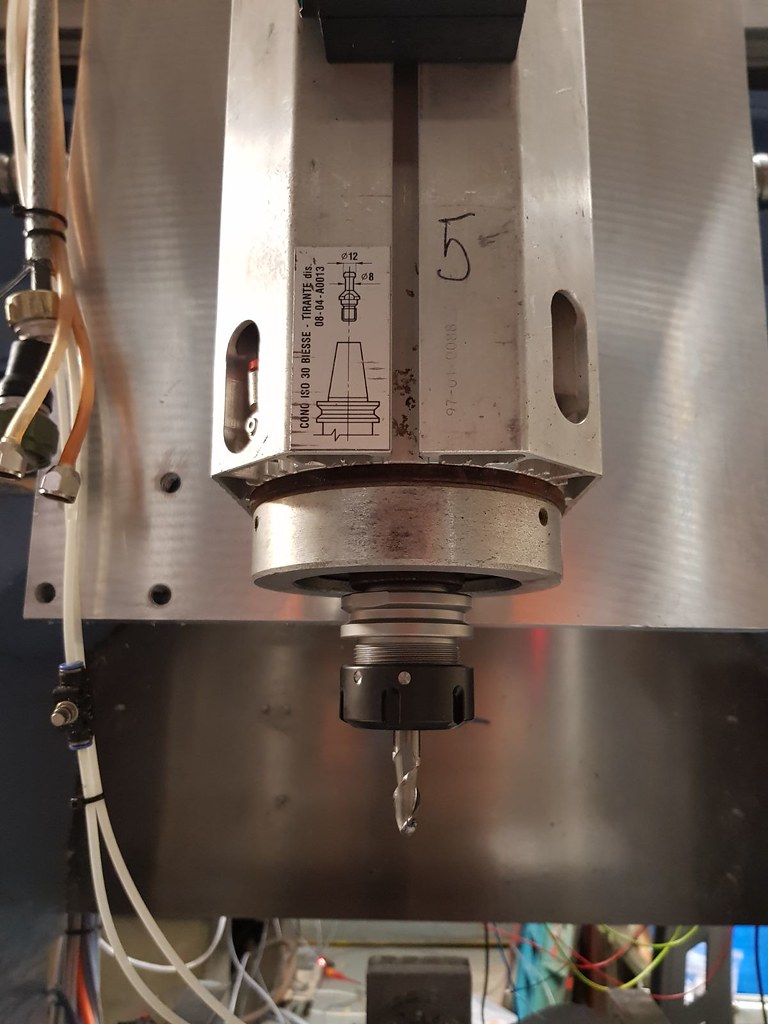

So Thor has had a bit of an upgrade / make over.

Spot the difference.

-

The Following User Says Thank You to Chaz For This Useful Post:

-

Go on Chaz give us a clue

On another note what is the max spindle speed and a link to it would be nice...Clive

The more you know, The better you know, How little you know

-

12-10-2017 #7

I know the answer but you told me lol having seen Thor though I could have spotted it anyway ;)

Congrats ;)http://www.mycncuk.com/threads/10880...60cm-work-area My first CNC build WIP 120cm*80cm

If you didn't buy it from China the company you bought it from did ;)

-

12-10-2017 #8

Its an HSD ES909. 6.8KW 24K RPM with ISO 30 tool holding. Small issue to actually power it but working on that. It runs happily off 220V, even though its a 380V unit. I cant get to the wiring to Delta the motor (these came as options for both voltages) so I'm hoping that I can run off 220V for now. It has two thermisotors which will trip if it gets too hot. I dont need to cut at 6 KW, even at 2KW im removing a fair bit of material and I now have an tool changer. Buying balanced ISO 30 holders is pricy but will build up a collection once I am happy that this works reliably.

-

The Following User Says Thank You to Chaz For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 9 users browsing this thread. (0 members and 9 guests)

Reply With Quote

Reply With Quote

Bookmarks