Hybrid View

-

15-02-2017 #1

Hello Jack

If I understand correctly, you have a project that you are now ready to commercialise. This will require manufacturing of plastic electronics housings and mounting brackets, for which you are considering cnc milling as the manufacturing method.

I would just suggest at this point that this possibly not commercially sound, and that you should consider vacuum forming, injection molding (or other plastic molding process), or closed mold GRP, etc. You may also consider purchasing an existing enclosure from one of a multitude of manufacturers/supplier of cheap enclosures.

CNC milled plastic may be commercially viable for simple flat profiles, or if only small quantities are required, but for example, an electronics enclosure (even a small one) milled from thick stock material has a high degree of material wastage.

Having said that, you may still need a CNC router for assisting to make your prototype vacuum forming molds and/or composites molds, which would typically be made in wood or aluminium. Another option, using your 3D printer, is that you could 3D print molds/patterns for brackets/boxes/etc then take composites molds from the printed models. You can also send 3D printed models of molds to an investment casting foundry and receive back an accurate aluminium or steel casting ready for prep/use as your plastics/composites mold.

I would recommend looking at vacuum forming, as it is quite simple, especially for small parts.

Regards, Jono

-

16-02-2017 #2

Hi Jono

My case has 5 PCBs in it in different orientations and types of mounting as well as fixings for mounting onto tripods (technically for injection moulding but work fine when heated and pressed into plastic).

I have looked at injection moulding but the starting costs put me off quite a bit.

And vacuum forming and off the self cases wont work because of the requirements of the internal layout.

The case is basically two flat 15-16mm sheets pushed together with their internals milled out for the PCB, sensors and connectors.

Works out at around £5 per case using Acetal and £1 using Polypropylene. So material cost is not a problem with these solutions.

This is why I am aiming for milling because it should give me the quality people are after with a product as well as it being at a low price point similar to the 3D printing solution.

Unless if I am missing something here? xD

-

16-02-2017 #3

Well it's certainly a lot more viable for low scale production than 3D printing is... It all comes down to how much volume you are expecting.

Injection tooling is indeed pretty expensive, only really makes sense if you are selling relatively high volumes and can spread the cost against at least several thousand units. I didn't pay for it myself but when we had the tooling made up for a drone I designed I think it was in the order of $10,000 to get the molds made (in china).

You would probably find a CNC a useful addition even just from a prototyping stand point - 3D printers are great, but the ability to work with PCBs, a variety of plastics, composites and some metals opens up more options to you that might be useful... not to mention much faster for making most things.

6040 is very much a generic term - some manufacturers are better than others, especially on the electronics front... One advantage of just buying a frame and adding your own electronics is that you can buy some better kit which you can then transfer to another machine if you decide you need something bigger or better.

I would recommend that you go for one with proper profile rails (e.g. HG20) rather than round rail - they are far superior. That particular machine you linked to actually simply has completely unsupported round rail for the X-axis gantry - don't bother with that... I had a similar machine in the past and there is a significant amount of flex from that design even when just pushing the spindle with your hand.Last edited by Zeeflyboy; 16-02-2017 at 04:15 PM.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

-

16-02-2017 #4

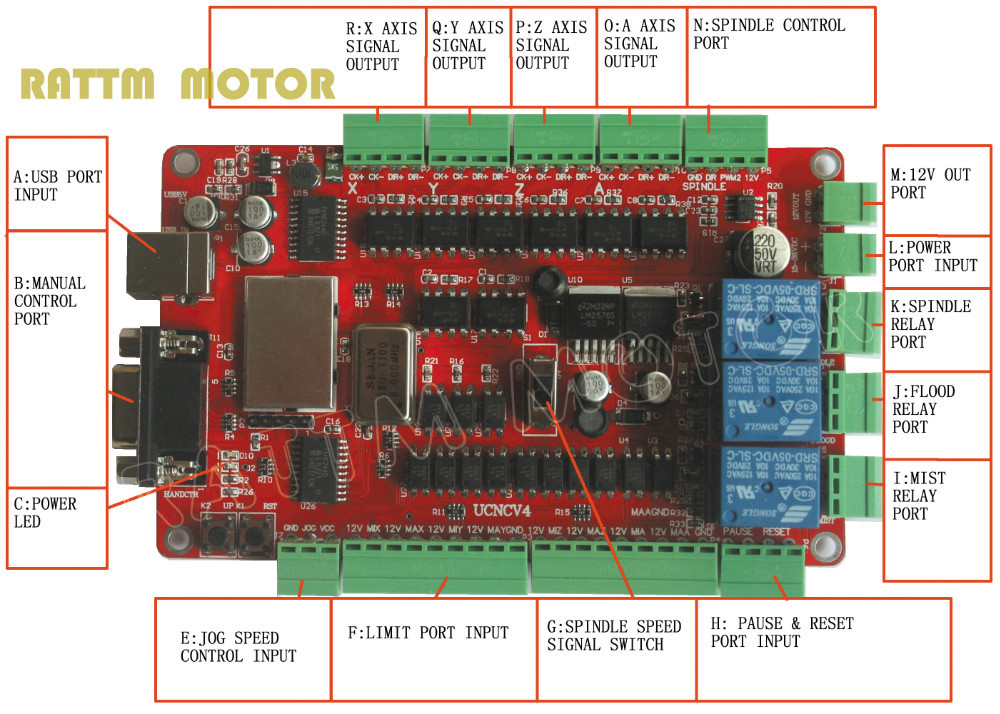

Spent a few hours looking into control boards and stuff.

People where saying the parallel boards that come with the China CNC machines are not worth it (because they are limited to just doing stepper control) so I would rather not use them.

Boards like the TinyG are controllers in themselves (I thought they worked with Mach3, bad YouTubers misleading me there), they don't run with software like Mach3 because they are hardware controllers.

They take the Gcode and control the motors, while Mach3 is a softwarecontroller that sends the movement data/signals to the drivers directly via serial or other interface.

I think what I am after is one of these "breakout boards".

This one (which comes with a lot of the stepper kits) http://www.ebay.co.uk/itm/262849334835

Looks to be what I am after.

4 Axis (only need 3) stepper control, spindle PWM, 3 relays for pump, air etc, home/limit switches and a couple IO ports.

Still China made but it comes with the motor kit so it should work fine with that setup.

That is the thing. I am not expecting more than 100. Probably not even 50. But at least 25 to make it worth doing the production run.

I have always wanted a CNC table/mill. I want to do a few personal wood projects and some 5-10mm aluminium plate and I think now is a good time to get one.

That rail is a concern. There have been a few videos demonstration this but for what I am doing I don't think it will be that bad?

Most said it was okay though larger jobs it started to cause problems.

I really do like the idea of putting a kit together rather than buying a premade one.

http://www.ebay.co.uk/itm/EU-Stock-4...QAAOSwDFNWFJQE

This one looks the the standard 6040 and is around ~£1,500

But I could put together this kit together for around £1,200. But I get the upgraded 2.2kW spindle, controller and beefer steppers.

Base - £650 - https://www.aliexpress.com/item/6040...308.0.0.4cDNN7

2.2kW spindle/driver - £200 - http://www.ebay.co.uk/itm/252593036650

Steppers - ~£230 - https://www.aliexpress.com/store/pro...612.0.0.NtqLm6

Stepper mounts - ~£15 - Trying to find some EU stock. Only China atm :/ https://www.aliexpress.com/item/3Pcs...999.268.f7AXAm

Cables, Water pump, Tube, cable bendy thing etc - ~75-100

Sounds like a better deal to me...Last edited by JOGARA; 16-02-2017 at 09:47 PM.

-

18-02-2017 #5

I would really just avoid those unsupported gantries like the plague... yes they may be ok with plastics and wood but they still limit how fast you can push it and will limit you in the future as well if you look to do some harder materials. It is not an area to cut costs imo as it's extremely difficult to upgrade or improve it later without just buying a new machine (which is what I ended up doing).

What is your time scale? I'm probably building myself a new bigger CNC over the next couple of months and the barebones X6-2200L mechanics would be up for grabs once I've done the machining I need to do for you to go to town on with your own electronics. That's like your generic 6040 but with proper profile HG20 type linear rails.Last edited by Zeeflyboy; 18-02-2017 at 01:40 PM.

-

16-02-2017 #6

Hello Jack, you've obviously done your homework on that stuff, and your part/design/method sounds to be even quite elegant.

Re injection molding, tooling should fit in a $5k envelope I would have thought, especially if your 'half shells' can be a mirror of each other, i.e. a single part.

Regards, Jono

-

The Following User Says Thank You to jono5axe For This Useful Post:

-

30-03-2017 #7

Is it worth paying £735 more for the X8?

X6

(X)355×(Y)510×(Z)85mm

57BYGH76-3A steppers

X8

(X)565×(Y)770×(Z)85mm

60BYGH86-4.2A steppers

Controller wise, the X6 uses Mach3. The X8 has an embedded system.

Does it still have usb input for Mach3?

The nearly double workspace is tempting...

Just don't fancy only using their hardware controller.

Thinking about it, £735 is a lot... Never mindLast edited by JOGARA; 30-03-2017 at 10:14 PM.

-

31-03-2017 #8

Bigger is good, if you need the space...

Bigger also however means less rigid for the same given design (as is the case here), so if that space isn't going to be used then it does have a negative aspect to consider.

I'm sure they could supply the X8 with the black control box if requested.

-

31-03-2017 #9

Went with the X6.

Don't really need the size of the X8, yet :p

Ordered a full set of collects and some 1mm and 3mm bits.

Looking at vices, got 2 cheapo ones from Ali, they look okay but not proper strong.

Will see if they work okay or not. If not, can use them for lighter material at least.

-

11-04-2017 #10

Not fully set up yet. Wish the cables were longer so I could have the controller elsewhere.

Done some tests and it looks to work well.

Just got to get some distilled water and some bits for my air compressor and we should be good to go!

The whole rig feels super strong. Not like steel strong but nothing moves if you push against any faces.

The only thing that came broke was the infamous pump...

Last edited by JOGARA; 11-04-2017 at 11:47 PM.

Thread Information

Users Browsing this Thread

There are currently 2 users browsing this thread. (0 members and 2 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks