Thread: Advice needed for Z Design

Threaded View

-

09-09-2012 #1

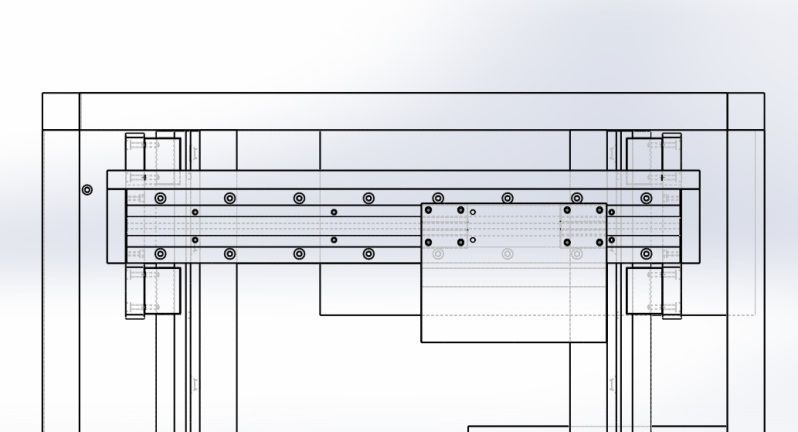

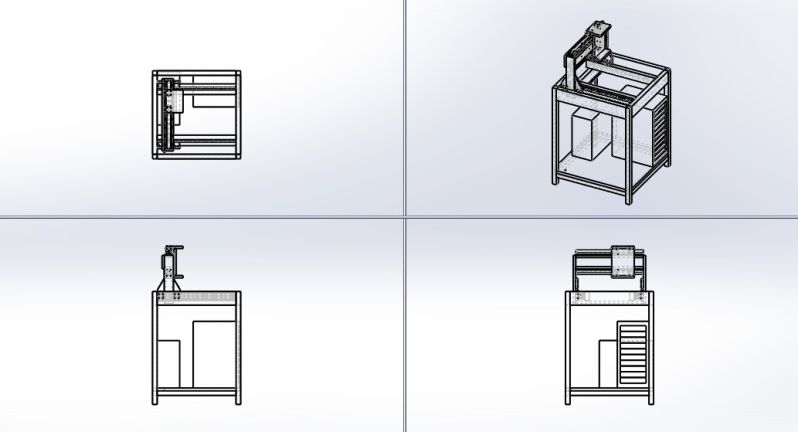

I have an area to mount rails for my Z axis of 240 vertically within 200 accross the plate.

I'd basically just like personal opinions on which you think would be best to use in my situation.

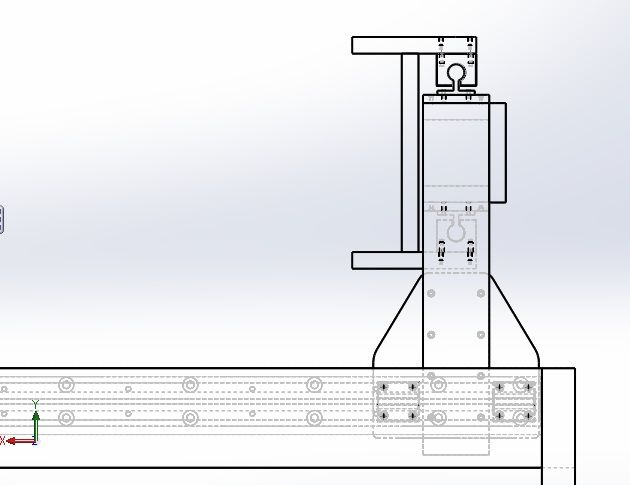

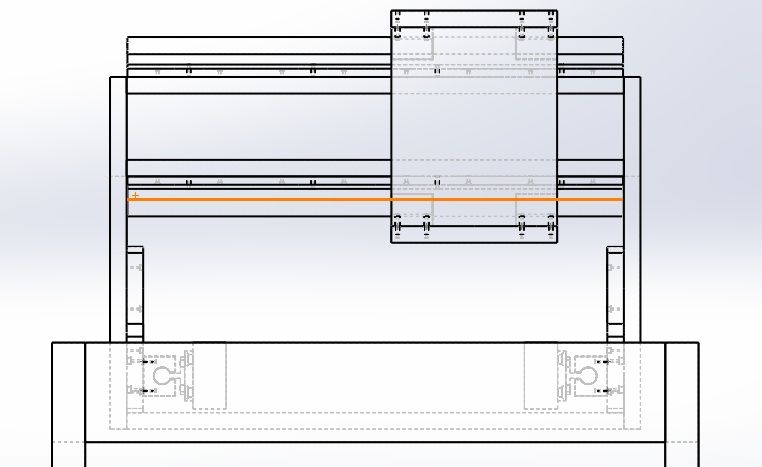

I'm thinking of using 2 rails for the Z equally spaced about centre line of the plate, with the centre free for the ball nut. If it helps at all I am also planning to mount a gear o'end the ballscrew, which will be connected to a pulley belt, which will be connected to the stepped motor mounted upside down inline with the centre of the gantry and inline centre of the z plate.

I'm unsure on whether to use fully supported rail or the profile hiwin rail for this.

Please can i have some help, ideas, suggestions?

Thanks

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Advice needed on Amadeal

By croy in forum General DiscussionReplies: 13Last Post: 21-08-2015, 01:28 PM -

Z-Axis design and advice

By Mad Professor in forum Gantry/Router Machines & BuildingReplies: 22Last Post: 06-04-2013, 11:00 AM -

Gantry design advice please

By D-man in forum Gantry/Router Machines & BuildingReplies: 10Last Post: 07-11-2012, 04:17 PM -

First steps, advice needed

By Wobblycogs in forum Gantry/Router Machines & BuildingReplies: 6Last Post: 02-11-2012, 02:30 PM -

CNC Design and advice

By Mad Professor in forum Gantry/Router Machines & BuildingReplies: 23Last Post: 20-09-2010, 03:25 PM

Reply With Quote

Reply With Quote

Bookmarks