Thread: Triac Z height issues

-

30-11-2023 #1

can anyone offer any suggestions?

got a triac VMC and its starting to have z height issues. i do a lot of engraving and i set the z to zero, do a 5min job and when its finished its 0.6mm out.

ive done half a turn on the z gib screw but this hasnt made any difference, the screw is pretty tight.

all suggestions welcome.

-

30-11-2023 #2

so an update

with spindle off and z in the air. if i move x and y around manually z doesnt change.

if i start the spindle and dont touch anything else, the z height drops.

so maybe some interference? .

-

30-11-2023 #3

Sounds like interference is getting into the Z step/dir signals..

Is it still the original spindle?Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

30-11-2023 #4

-

30-11-2023 #5

Stepper or Servo machine?

Fanuc or PC control?Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

30-11-2023 #6

-

30-11-2023 #7

Not that original then.

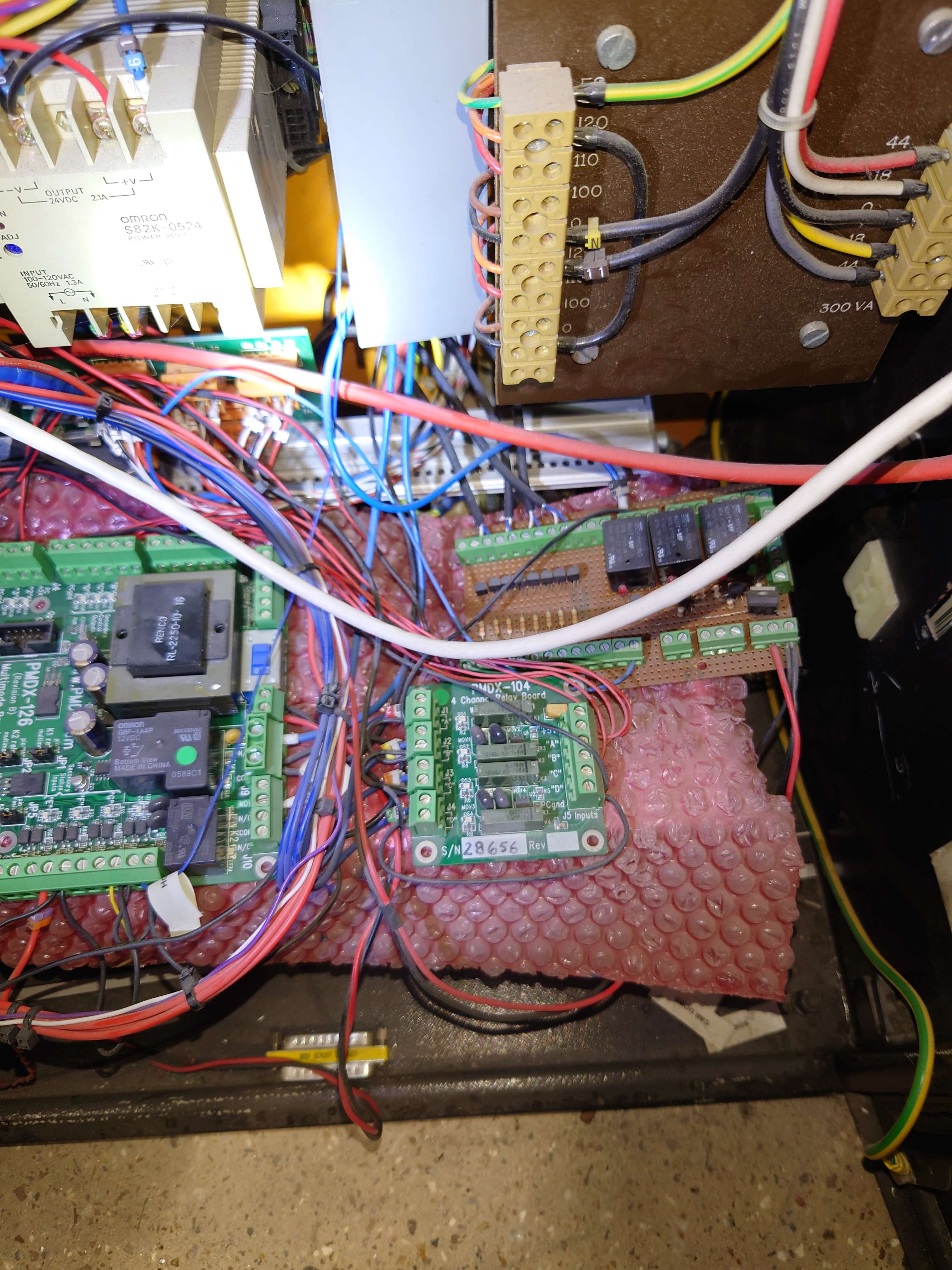

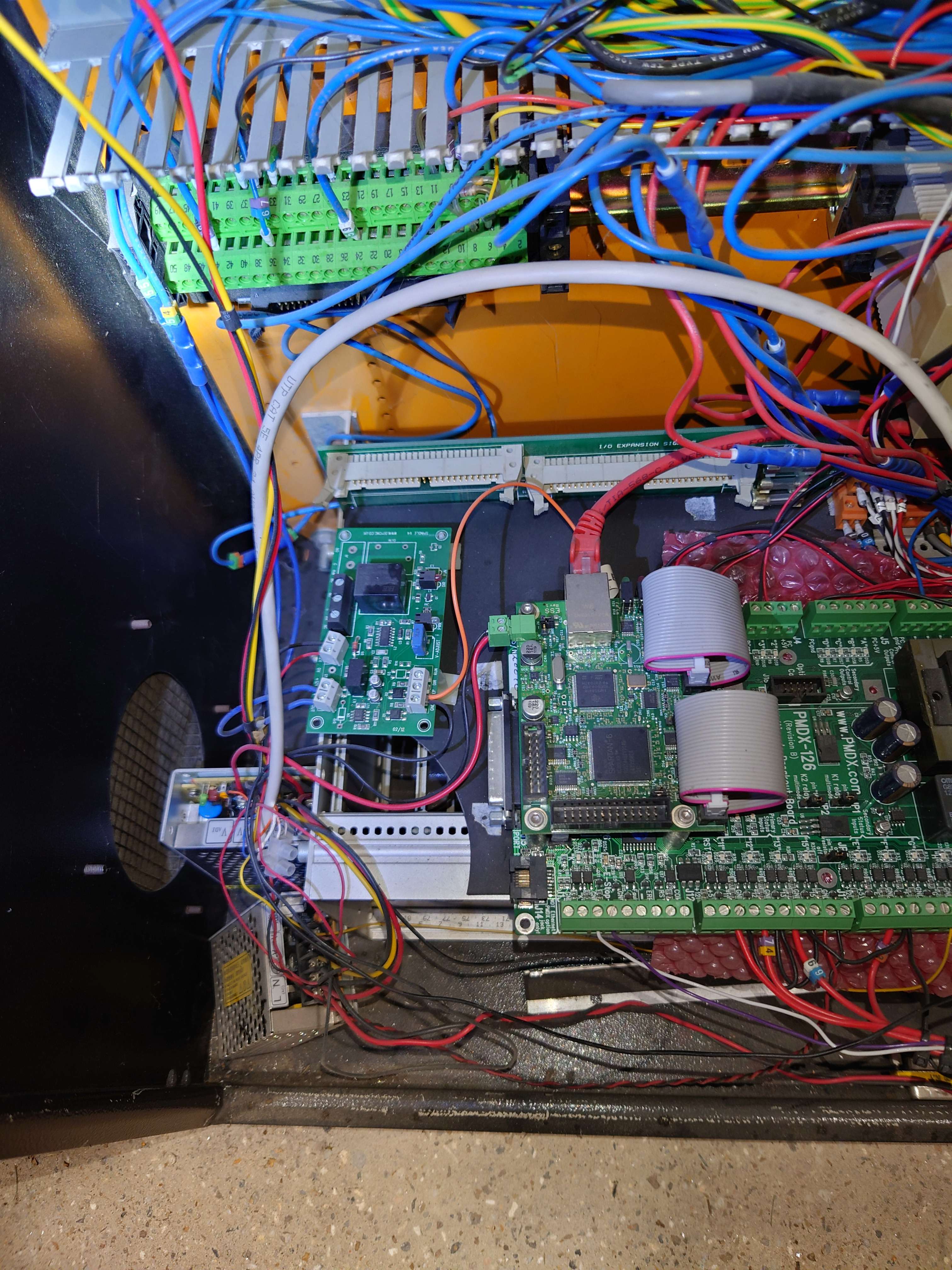

What stepper drivers are fitted?

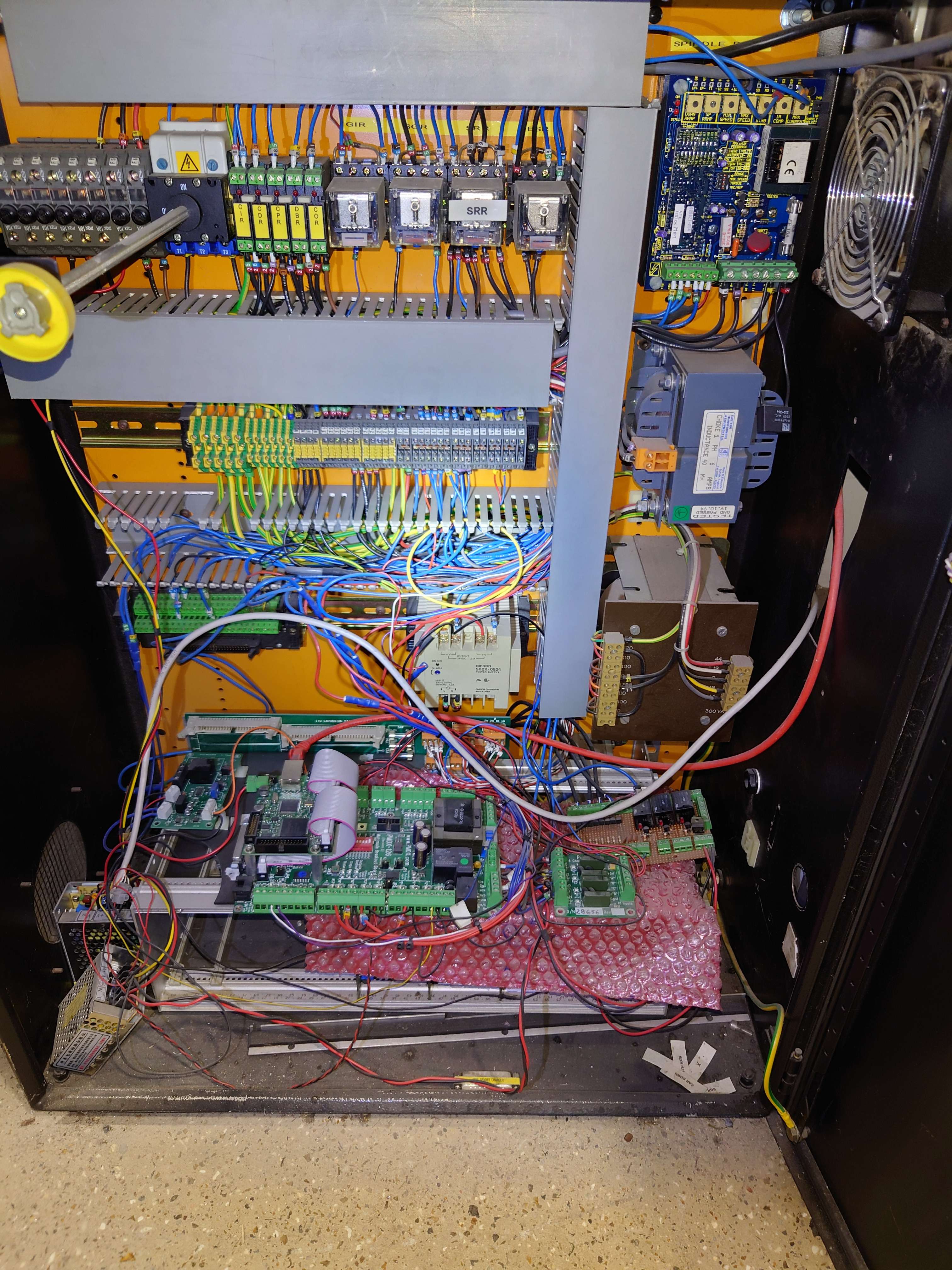

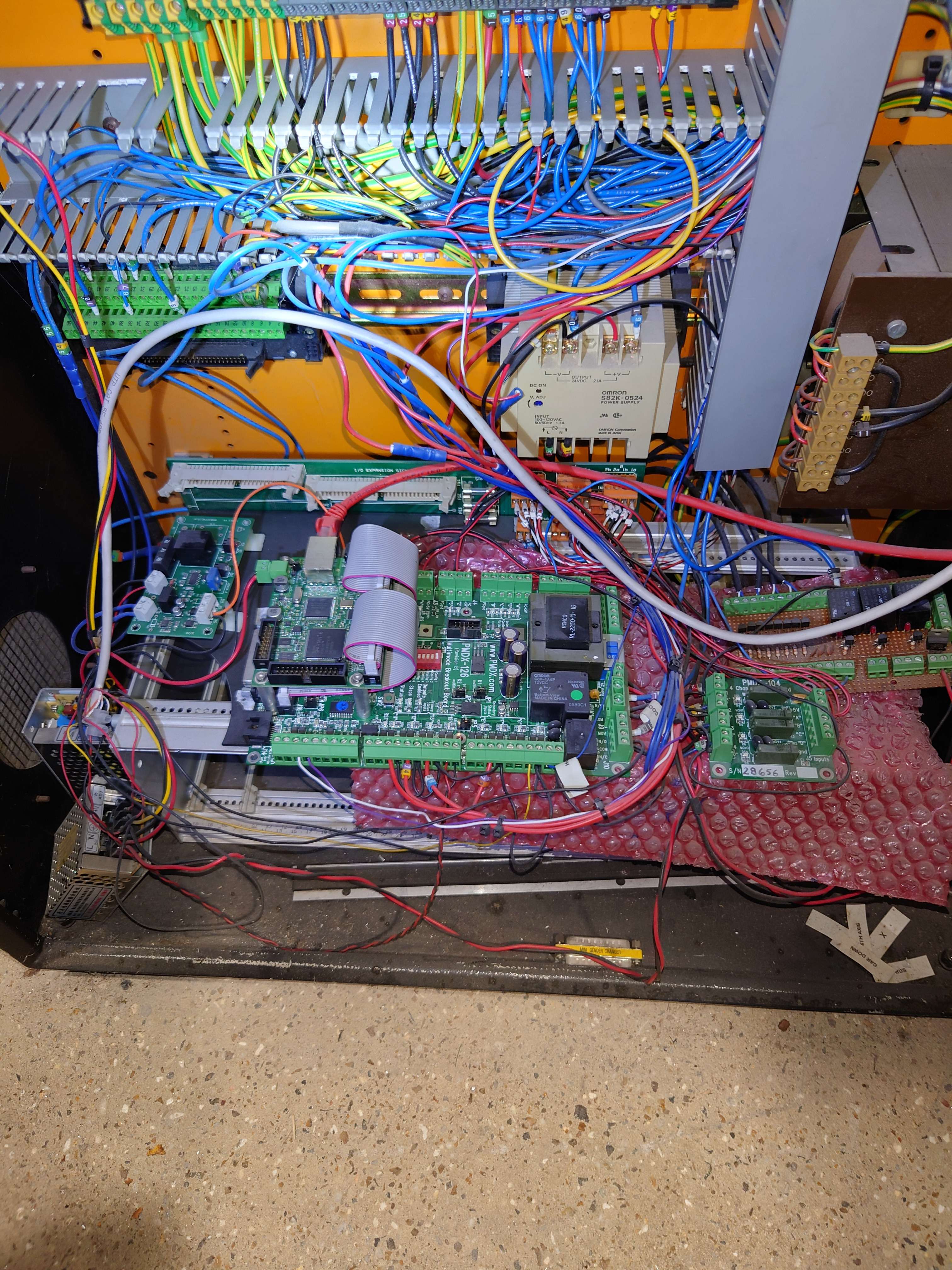

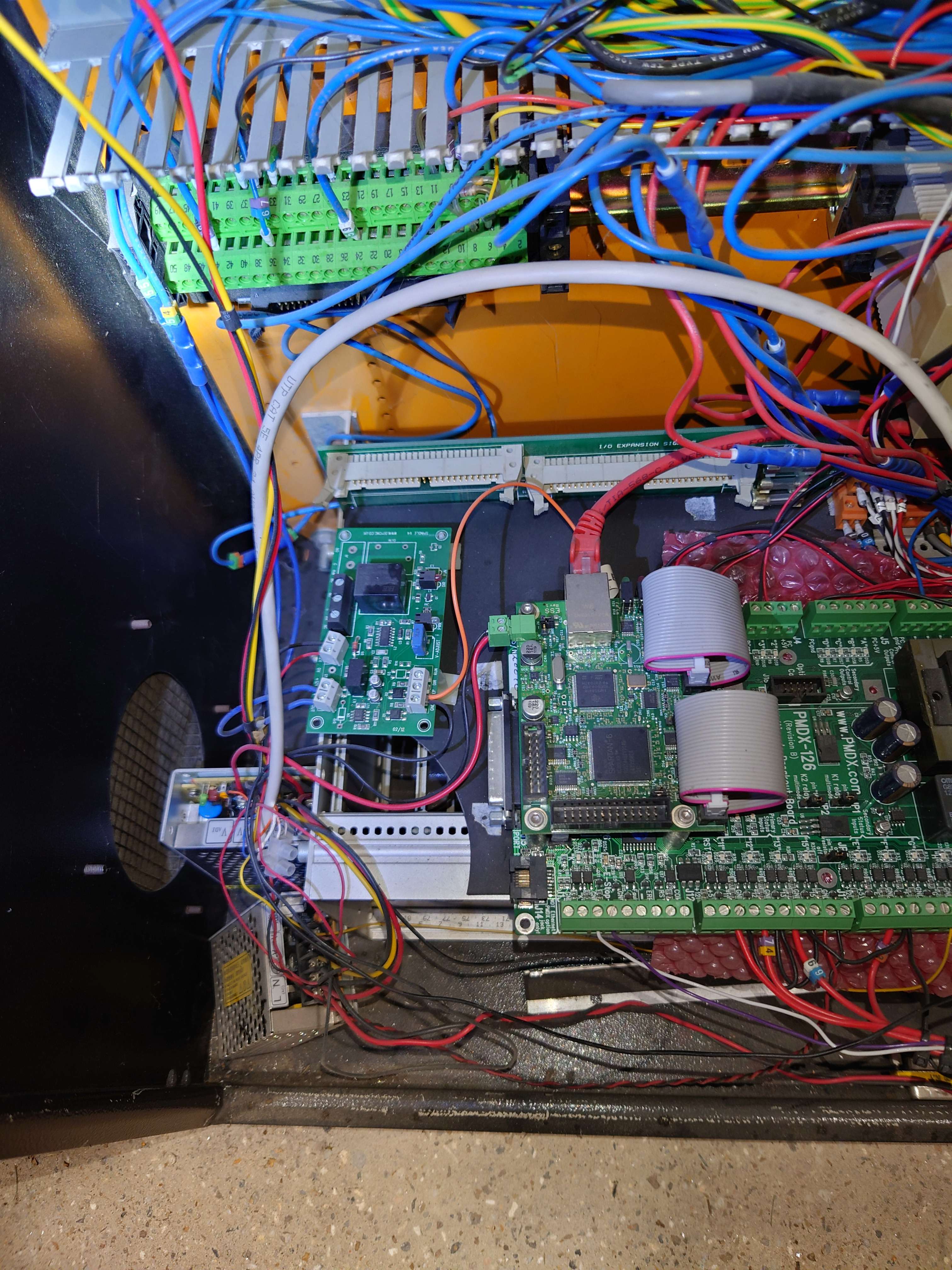

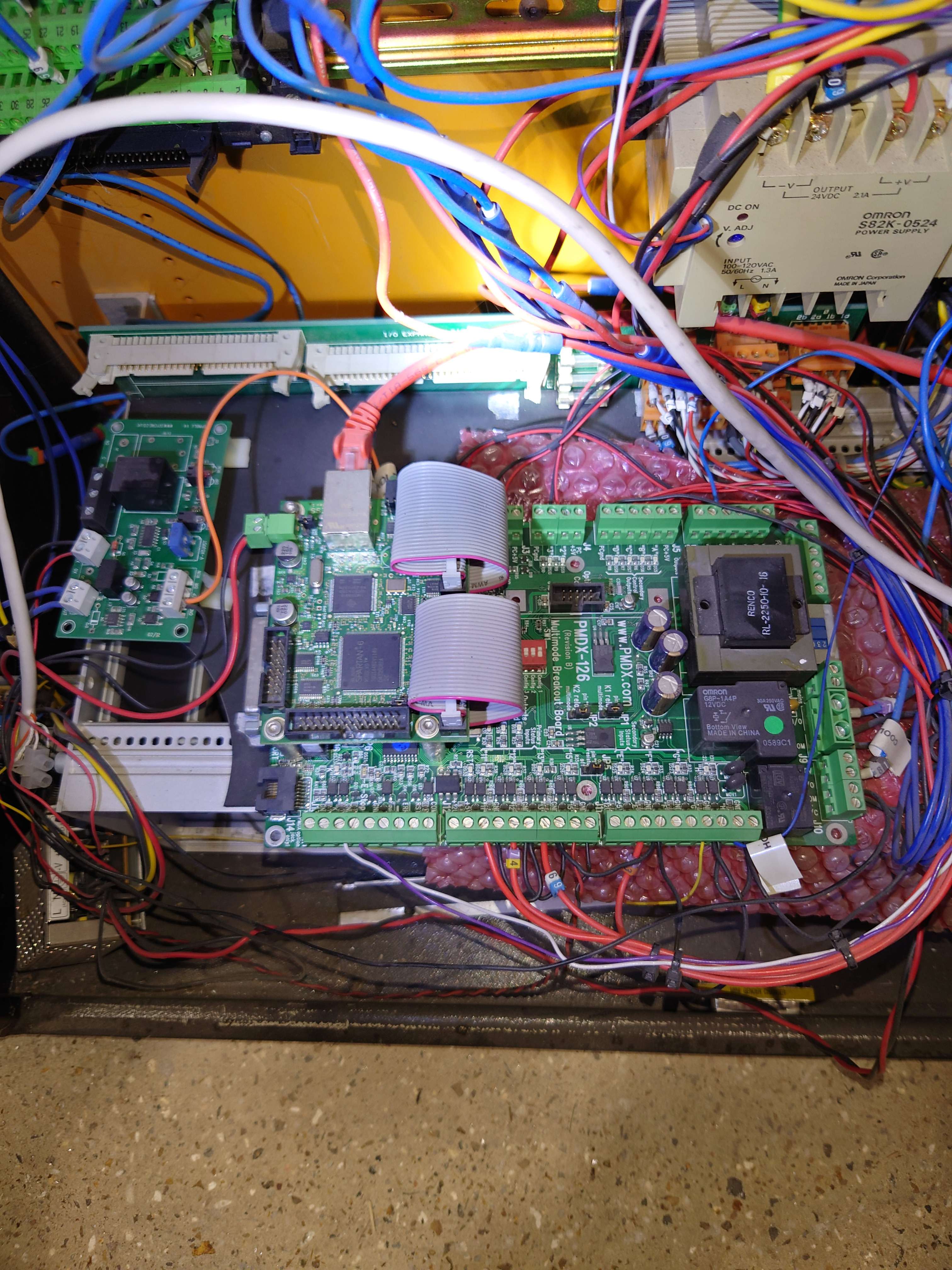

A photo of the control cabinet would probably be good.

My thoughts to it having only recently started, is probably something starting to fail.

Probably worth a run around the control cabinet, making sure all screw terminals are tight, and unplugging and reseating any pluggable connectors, just to make sure there's no corrosion in any of them.

Then I'd probably be looking at the spindle motor, and the controller.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

30-11-2023 #8

well nearly original ;)

original stepper drivers.

cant get a photo till im back in workshop tomorrow now, its a bit messy inside be warned.

ill check all connections tomorrow

i did send the spindle motor away a number of years ago to be tested and reconditioned, set me back £500

-

30-11-2023 #9

That potential cost is why I swapped my spindle motor for a servo.

Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

01-12-2023 #10

not been in the cabinet for a while, its still messy

Thread Information

Users Browsing this Thread

There are currently 4 users browsing this thread. (0 members and 4 guests)

Similar Threads

-

Gantry to bed height.

By m.i.k.e in forum Gantry/Router Machines & BuildingReplies: 20Last Post: 05-07-2020, 05:46 PM -

Tool height sensor.

By Ollie78 in forum General DiscussionReplies: 10Last Post: 27-06-2019, 09:32 PM -

Z axis height setter

By phill05 in forum General DiscussionReplies: 7Last Post: 29-11-2016, 01:14 PM -

Z Height - Max?

By Chaz in forum Gantry/Router Machines & BuildingReplies: 6Last Post: 04-02-2016, 11:18 AM -

Height Mapping?

By Tenson in forum General DiscussionReplies: 3Last Post: 26-10-2012, 11:40 PM

Reply With Quote

Reply With Quote

Bookmarks