Thread: Emco PC120 Turn

-

03-08-2016 #21

Thanks. I tried to put on a dial gauge last night but space is an issue. I need a smaller setup.

In terms of home position, I am hoping that with electrical proximity switches, this will be fairly accurate. I will do some tests later.

On the sensor for the spindle, I noted what I recall to be 3 wires coming out from the sensor. Let's assume this is a single pulse (or needs to be converted somehow), is there normally an input into the BOB or similar to read these? If the sensor is damaged, is there a part that can be bought that will give me what I need (like a generic generator that works with most setups)?

Many thanks for your help / info, been very useful.

-

03-08-2016 #22

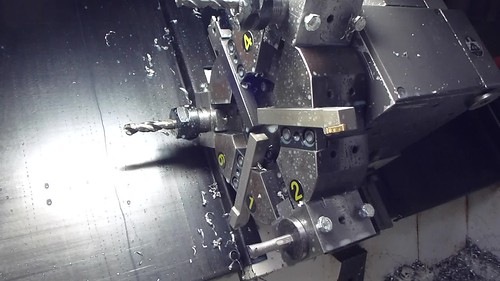

Where the cutting edge is, and what direction the material has to turn in relation to the cutting edge. The turret on my lathe is rear mounted with the disc machined so 12mm tools have their cutting edge level and facing down when at the spindle (click the pic if you want to see a vid of it changing position a couple times)

Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

03-08-2016 #23

-

03-08-2016 #24

There's not a setting for that. You'll need to ensure however you produce your G-code does the spindle direction setting.

You could allocate blocks of tool numbers that rotate certain directions, then use the M6 macro to check and set spindle direction depending on tool number.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

03-08-2016 #25

-

07-08-2016 #26

Struggling with two items.

Spindle, doesnt like the one plugin. It works oddly if I disable the plugin but then not on restart of Mach. Ive tried the Matty Zee plugin, seems to work, the drive 'stops' if the start up speed is too high (I need to slow down the ramp time perhaps), and the motor speeds / what mach3 thinks its doing dont match. I dont have feedback on the motorspeed at the moment.

The main other issue is that Fusion CAD is putting some odd code in which is causing me to hit limits. The consensus is to use the Fanuc turning Post Proccesor. It works, no errors, but I get this:-

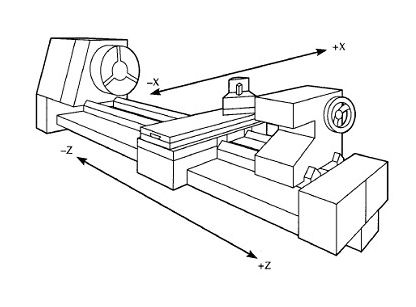

I'm less knowledgeable on turning code than milling however what I dont understand is why its moving to X33 in this line - N20 G0 X33. Z1.414. The way my lathe works is X is a negative number at the top and it should be moving to zero. So X-32 will be my current location when homed up top. This is a slant bed lathe, would this be correct? Ive tried to reverse the X direction in the setup on Fusion but gives me the same output.

%

O1001

N10 G98 G18

N11 G21

N12 G50 S6000

N13 G28 U0.

(FACE1)

N14 T1313

N15 G54

N16 M8

N17 G98

N18 G50 S3000

N19 G96 S200 M3

N20 G0 X33. Z1.414

N21 G1 X15.828 F1000.

N22 X13. Z0.

N23 X-1.6

N24 X1.228 Z1.414

N25 G0 X33.

(PROFILE1)

N26 M9

N27 G98

N28 G50 S3000

N29 G96 S200 M3

N30 G0 X33. Z1.345

N31 X14.968

N32 G1 X14.828 F1000.

N33 X12. Z-0.069

N34 Z-6.55

N35 X12.98

N36 X15.808 Z-5.136

N37 G0 Z1.404

N38 X13.828

N39 G1 X11. Z-0.01 F1000.

N40 Z-6.55

N41 X12.

N42 X14.828 Z-5.136

N43 G0 Z1.404

N44 X12.828

N45 G1 X10. Z-0.01 F1000.

N46 Z-4.775

N47 G18 G3 X11. Z-5.798 R1.3

N48 G1 Z-5.8

N49 X13.828 Z-4.386

N50 G0 Z1.404

N51 X11.828

N52 G1 X9. Z-0.01 F1000.

N53 Z-4.535

N54 G3 X10.5 Z-5.034 R1.3

N55 G1 X13.328 Z-3.619

N56 G0 Z1.404

N57 X10.828

N58 G1 X8. Z-0.01 F1000.

N59 Z-4.5

N60 X8.4

N61 G3 X9.5 Z-4.622 R1.3

N62 G1 X12.328 Z-3.208

N63 G0 Z1.404

N64 X9.828

N65 G1 X7. Z-0.01 F1000.

N66 Z-4.5

N67 X8.4

N68 X8.45

N69 X8.5 Z-4.501

N70 X11.328 Z-3.087

N71 G0 Z1.404

N72 X9.279

N73 G1 X6.45 Z-0.01 F1000.

N74 Z-4.5

N75 X7.5

N76 X10.328 Z-3.086

N77 G0 Z1.404

N78 X8.729

N79 G1 X5.901 Z-0.01 F1000.

N80 Z-4.5

N81 X6.95

N82 X9.779 Z-3.086

N83 G0 Z0.614

N84 X7.729

N85 G1 X4.901 Z-0.8 F1000.

N86 Z-5.

N87 X8.4

N88 G3 X10. Z-5.8 R0.8

N89 G1 Z-6.55

N90 X12.828 Z-5.136

N91 X13.838

N92 G0 X33.

N93 G28 U0. W0.

N94 M30

%

Thanks in advance.

-

07-08-2016 #27

This is a G0 command, so its machine coordinates? I dont see anything in post processor to tell it not to use these. Not sure actually.

-

07-08-2016 #28

Ok, based on this, my X is upside down?

The turret sits on the top. So it should be showing +36, not -36 (relative to the zero line)?

-

07-08-2016 #29

Ok. Some progress. Firstly, if something has 'professionally' been converted. Check everything.

X was upside down.

Steps were wrong. Explains why some circles too big and some too small.

Still having a lesser issue. I should end up with a 10mm profile but the G Code is not making that happen. The left over sizes are too large. I suspect its something on the Fusion tooling side, its as if its adding in some additional size somewhere. There is nowhere below where I can get a 10mm and 5mm profile. The closes to zero the X goes is X7.729.

N25 G98

N26 G97 S4000 M3

N27 G0 X17. Z1.347

N28 X12.971

N29 G1 X12.828 F250.

N30 X10. Z-0.067

N31 Z-4.185

N32 G18 G3 X10.981 Z-4.541 R1.794

N33 G1 X13.809 Z-3.127

N34 G0 Z1.404

N35 X11.828

N36 G1 X9. Z-0.01 F250.

N37 Z-4.024

N38 G3 X10.5 Z-4.335 R1.794

N39 G1 X13.328 Z-2.921

N40 G0 Z1.404

N41 X10.828

N42 G1 X8. Z-0.01 F250.

N43 Z-4.

N44 X8.413

N45 G3 X9.5 Z-4.084 R1.794

N46 G1 X12.328 Z-2.67

N47 G0 Z1.404

N48 X10.279

N49 G1 X7.45 Z-0.01 F250.

N50 Z-4.

N51 X8.413

N52 X8.456

N53 X8.5 Z-4.001

N54 X11.328 Z-2.586

N55 G0 Z1.404

N56 X9.729

N57 G1 X6.901 Z-0.01 F250.

N58 Z-4.

N59 X7.95

N60 X10.779 Z-2.586

N61 G0 Z0.62

N62 X7.729

N63 G1 X4.901 Z-0.794 F250.

N64 Z-5.

N65 X8.413

N66 G3 X10. Z-5.794 R0.794

N67 G1 Z-8.544

N68 X12.828 Z-7.13

N69 X14.

N70 G0 X17.

-

07-08-2016 #30

OK, sorted I believe. Changed from Radius to Diameter mode. Parts are now basically the right size.

Thread Information

Users Browsing this Thread

There are currently 3 users browsing this thread. (0 members and 3 guests)

Similar Threads

-

Mach Turn

By Kai in forum CAD & CAM SoftwareReplies: 5Last Post: 02-08-2016, 02:40 PM -

Denford Star Turn 3

By MarkBrown in forum Workshop & EquipmentReplies: 2Last Post: 02-12-2014, 10:57 PM -

Getting the stepper to turn

By thorphar in forum General ElectronicsReplies: 0Last Post: 16-09-2014, 07:48 PM -

11 hours of trying to get the motors to turn, help please

By Wotsit in forum Stepper & Servo MotorsReplies: 19Last Post: 05-02-2013, 03:07 AM -

LED not turn on

By Awel in forum Motor Drivers & ControllersReplies: 1Last Post: 06-12-2011, 06:59 AM

Reply With Quote

Reply With Quote

Bookmarks