Thread: Emco PC120 Turn

-

31-08-2016 #41

-

31-08-2016 #42

i think the separate line was to move the z after the x. This is in a macro.

-

02-09-2016 #43

-

12-09-2016 #44

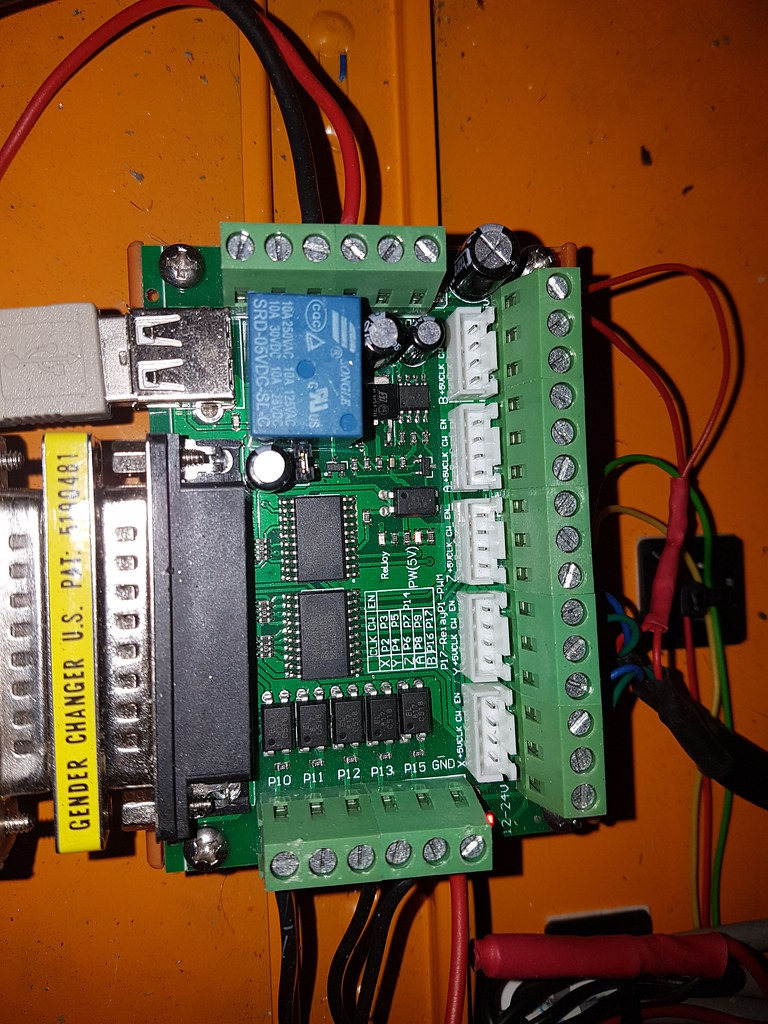

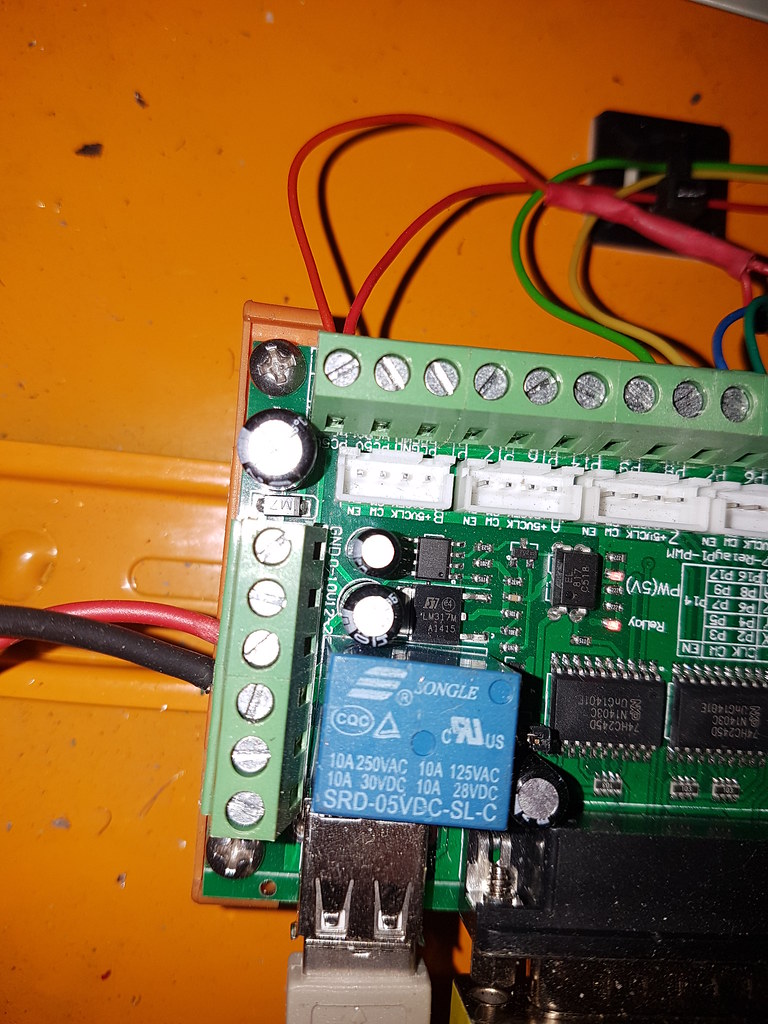

Does anyone know what BOB this is? I am looking to see why the flood coolant wont come on. I have no wiring diagram but managed to trace it to the main contactor, there is no 24V wired to switch it on and off. Need to find the relay output and wire it up. I found some generic looking BOBs online but nothing exactly the same. Suppose I could ring out each set of 2 output but prefer the manual so I can see more about the board.

I also need to figure out how to wire up the lube system however as the spindle uses RS485 logic, will have to find another way to do that. Does the lube system run full time when the spindle is on like in my Triac mill?

-

12-09-2016 #45

OK, found it.

https://www.google.co.uk/url?sa=t&rc...32479545,d.bGs

It's basically the same one in the link. Yay, at least now I can see some wiring options.

-

20-11-2016 #46

Managed to get the lube pump working however there are two wires that go to some sensor / switch on the Vogel unit. Does anyone know what it is? It looks like some form of solenoid, 24V to activate?

-

20-11-2016 #47

Looks a like a pressure switch, or possibly sensor.

What's stamped on the side of it?

And is there a small adjusting screw between the terminals? It may of been sealed over with some sealer/paint (if it has a screw, then it's most likely a switch)

.

Probably some form of monitoring that tells the controller that lube is actually being pumped. Where does the wiring go to?

Do you know if it's a one shot type pump (fires single shot every xx minutes), or a continual pressure pump (pumps/maintains pressure constantly)?Last edited by m_c; 20-11-2016 at 08:01 PM.

Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

20-11-2016 #48

The wiring goes nowhere. It ends with a wire with 2 ends and labelled 'lube pump'. Thing is - pump runs with a relay activated. I dont know what this does. I might try and open it to see.

The manual talks about only running the lube pump once the slides have moved 16meters. Since this is now a Mach 3 system, there will be no such logic.

-

20-11-2016 #49

Does anyone know what parting tool actually fits into this turret? Most are too long and cannot turn behind the turret when it does a tool change.

-

20-11-2016 #50

It's definitely a sensor of some kind, as it just connected via bog standard T-piece.

It could be the pump is designed to only run for a set period, after a set pressure has been reached, then switch off. If it's a continual pressure pump, then I suspect it's not meant to run continuously on such a small machine.

.

I'd guess just a pretty standard insert parting tool would work (small tip type, not big flat blade type), with the holder cut shorter if needed.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

Thread Information

Users Browsing this Thread

There are currently 2 users browsing this thread. (0 members and 2 guests)

Similar Threads

-

Mach Turn

By Kai in forum CAD & CAM SoftwareReplies: 5Last Post: 02-08-2016, 02:40 PM -

Denford Star Turn 3

By MarkBrown in forum Workshop & EquipmentReplies: 2Last Post: 02-12-2014, 10:57 PM -

Getting the stepper to turn

By thorphar in forum General ElectronicsReplies: 0Last Post: 16-09-2014, 07:48 PM -

11 hours of trying to get the motors to turn, help please

By Wotsit in forum Stepper & Servo MotorsReplies: 19Last Post: 05-02-2013, 03:07 AM -

LED not turn on

By Awel in forum Motor Drivers & ControllersReplies: 1Last Post: 06-12-2011, 06:59 AM

Reply With Quote

Reply With Quote

Bookmarks