-

27-09-2016 #1

Hi all,

our business has been steadily growing and we have been branching out into new fields. Besides the extremely popular and rare BCN3D Sigma 3D printers (voted best printer of 2016 by All3dp.com) we are starting up in light machine tools. We presented our range at the Bristol Model Engineering Societies exhibition this year with good interest and very positive feedback. Here is a write up of the whole exhibition (http://journeymans-workshop.uk/news/...stol-mex-2016/)

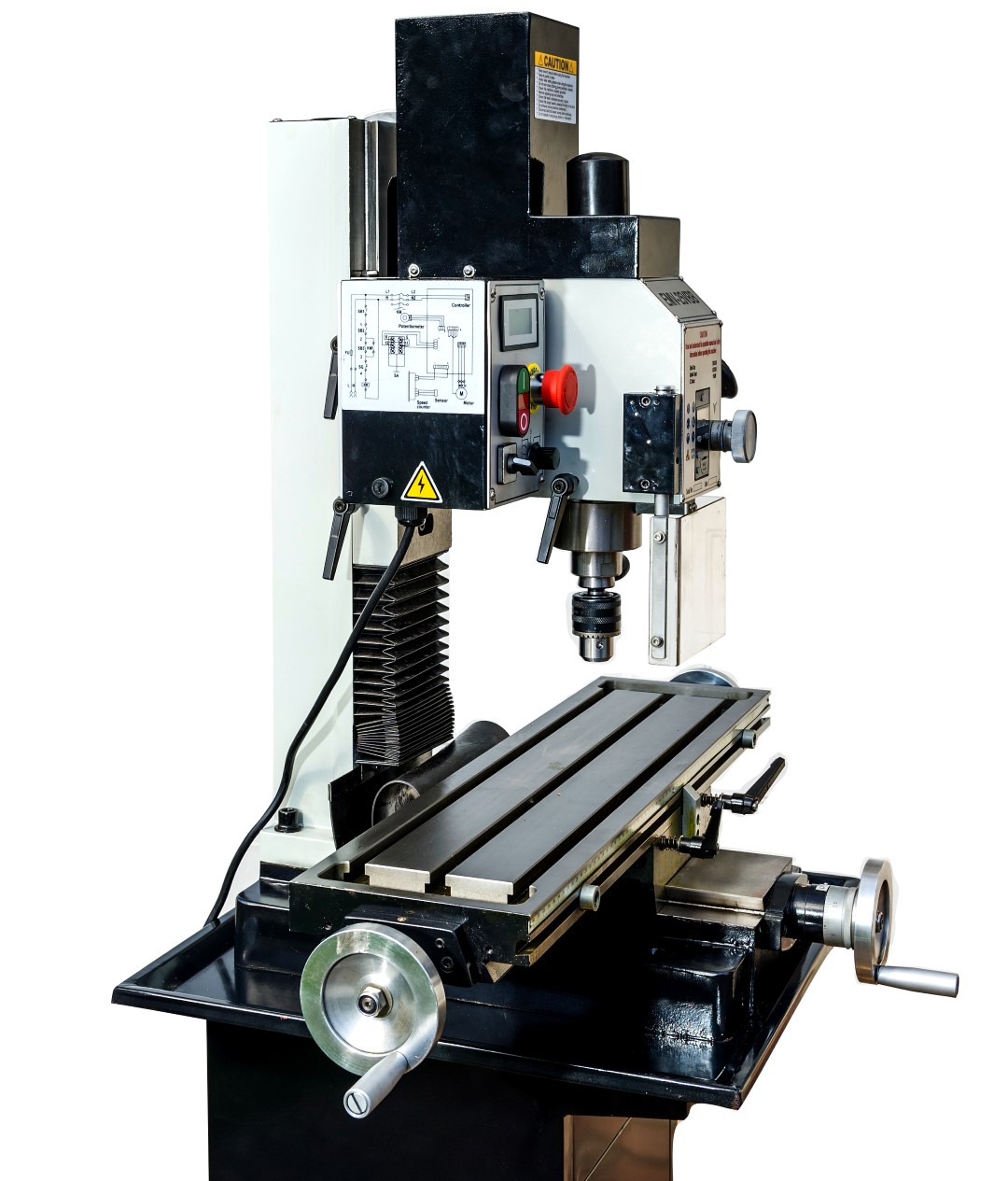

So without waffling on too much I present to you the EMV-25VBB (working on the name): https://emvioeng.com/shop/machine-to...lling-machine/

We have stock of all the bits you will need to get you started and yes I am working on a conversion kit and will be looking to expand into cutting tools at some point. In the mean time we are doing a bundle to get you started,

(https://emvioeng.com/shop/machine-to...achine-bundle/) With this bundle you will be well on your way to getting a very capable machine ready for making your own CNC conversion parts.

Bundle includes:

- Machine

- Stand and drip tray

- ER25 collet set

- ER25 safety wrench

- 5 off ER25 TTS style tool holder

- R8 3/4" collet.

Videos of the machine running to following very shortly along with the new larger CNC machine that I am hoping to tune a release before the end of the year.

Should you have any questions or comments do drop me a line.

Regards

Georgehttps://emvioeng.com

Machine tools and 3D printing supplies. Expanding constantly.

-

27-09-2016 #2

George,

Do these machines have a valid and traceable genuine CE certification ?

Not China Export ��John S -

-

27-09-2016 #3

-

27-09-2016 #4

Aren't the BCN3D Sigma 3D Printer's manufactured by Students in Barcelona?

-

28-09-2016 #5

That is pretty, please can we have a side view?

-

28-09-2016 #6

Hi all,

John: Yes, I have received a copy of a CE certificate of conformity. However I have my own inspection process based on the required ISO/EN standards like 12100:2010, EN 13128:2001+A2:2009 and EN 60204-1:2006. This means as an engineer, with the assurance that the technical file being held by the manufacturer and 100% inspection in the EU I am able to issue my COC.

Boyan: Thanks!

DavidB: yes they are a BCN university spin off. Very popular in the 3D printing community.

Robin: here you go

https://emvioeng.com

https://emvioeng.com

Machine tools and 3D printing supplies. Expanding constantly.

-

04-10-2016 #7

Thanks for your reply George,

Working in Barcelona now for 6 years I know that BCN Technologies was previously RepRapBCN .. underneath Fundacio CIM.. ( the University Polytechnica Catalunya UPC.. ) and they have been "letting" students to make and sell RepRap MendelMax copies using their SLS machines for 3 years... they sold a copy of RichRaps Delta as well..

Now they use paying students to manufacture their products and call it "work experience"..

They say they are "helping" local companies but they continue to kill them by supplying university designed and produced products. Do you also sell their DLP and LAser machines?

Fundacio CIM even quote against real companies to supply FabLabs with their "student made" machines ....at a much cheaper price because they cannot make a profit...

https://www.fundaciocim.org/en

Just so you know... :)

-

04-10-2016 #8

Yeah I know how they operate. Their Sigma printer is best in class and that is my best selling one. The DLP has not really taken off because of cost, I sell it but do not stock it. Same with the kits.

We had a client buy the laser but upon unboxing we saw it was not a ready product (being kind here) and had to send it back. Replaced it with a better one for less money. I have since dropped the laser from my range to be replaced with others shortly.https://emvioeng.com

Machine tools and 3D printing supplies. Expanding constantly.

-

04-10-2016 #9

George - I remember having a look at the Sigma printer (I think it was) at the Bristol show. I always wander round looking for ideas for my own builds! This was the first printer I have seen in the flesh with profile rails for guides, which must put the price up a bit. I was demonstrating my old Prusa printer on my club stand. It's a grotty old machine that is showing its age (and it wasn't that great to start with) but it has the benefit for demos that you can see all the working bits. The mark 2 will be a compilation of the best bits of all the machines I can find, and might even now use profile rails...

I'm a great believer in that old motto of the academic - pinch one person's idea and it's plagiarism. Pinch lots of peoples' ideas and it's research

-

04-10-2016 #10

Yeah they all do that :D

Neale, I think I remember you. You were in the second hall with the spark eroder on display? Have you seen the new Prusa addon with the 4 colours?

The linear rail was the reason I jumped at this machine as soon as I saw it. Now they are pretty common on the high end machines and it is about time too.

Thing with 3D printers, not many people in the building side of them have any schooling in straight flat and parallel. There is for example the assumption that linear rails are the above...

Anyway, the Sigma is the only machine that has not gone up in price over the past few months. We are trying very to keep it at the price it is. If you looked at an Ultimaker recently you will have noted the 2k+ price tag it has now....https://emvioeng.com

Machine tools and 3D printing supplies. Expanding constantly.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Super sieg x3 conversions

By dazza in forum Milling Machines, Builds & ConversionsReplies: 2Last Post: 19-02-2014, 10:28 AM -

RFQ: RFQ: Keyslot milling in alu round stock.

By Saracen in forum Projects, Jobs & RequestsReplies: 2Last Post: 05-09-2013, 09:42 AM -

RFQ: Parts for my hobby from your hobby

By Phobia1 in forum Projects, Jobs & RequestsReplies: 1Last Post: 18-01-2011, 02:57 PM -

Weiss Milling Machines

By abfa9358 in forum Milling Machines, Builds & ConversionsReplies: 0Last Post: 27-08-2009, 11:07 PM -

opinions on buying cnc milling machines

By DGH in forum Milling Machines, Builds & ConversionsReplies: 0Last Post: 27-05-2009, 04:47 PM

Reply With Quote

Reply With Quote

Bookmarks