-

17-03-2017 #41

-

21-03-2017 #42

A bit more measuring, head scratching, double/triple checking measurements, and I finally have a firm plan-

100mm diameter aluminium, machined and mounted to the original motor mounting plate, via the original countersunk bolts. The spacer contains two 6004 bearings to support a new drive shaft, which gets connected to the new servo via a flexible coupling. I would of preferred a smaller coupling, but the next smaller option was rated at less than the servos instantaneous torque, where as this one is rated at 2-3x the instantaneous with double that again for maximum torque.

There will then be a 15mm thick adapter plate bolted to the spacer, that provides something for the servo to bolt on to.

I started on the aluminium bar last night, and it so far has a big hole drilled through it, so now I have the final dimensions, I'm off to spin some dials for a while.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

30-06-2017 #43

The enclosure finally went back on a couple nights ago :-)

There was a bit of a delay getting the servo for the spindle, which meant it got delivered just as I entered my crazy time of year for events, and business sales were higher than normal, so I never had much time to work on it.

The spindle mount was done ye olde fashioned way on the manual lathe. I started with a bit 4" round alu, and after a bit time spent spinning handles, resulted in lots of swarf -

A 110mm square plate was cut and then turned to create a flange on one side to fit the spacer, and a recess on the other to fit the servo. It was then drilled and counterbored to accept 8 M5 bolts. 4 would of done, but 8 looked better!

The mount was then test fitted -

Things then stalled waiting for the servo motor, but when it arrived, assembly could begin in earnest.

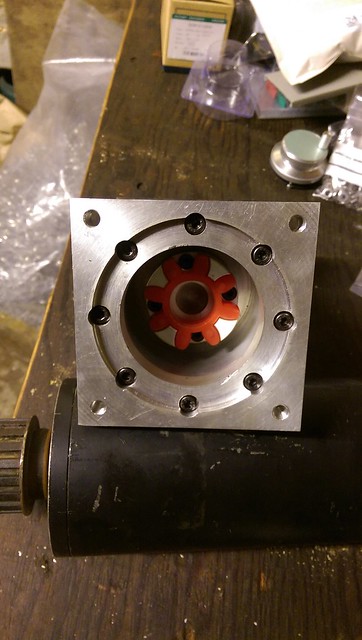

The extension shaft was cut to length, and a circlip groove machined in to locate it in the bearings. The flexible coupler was then installed -

And a new taperlock timing pulley on the opposite end-

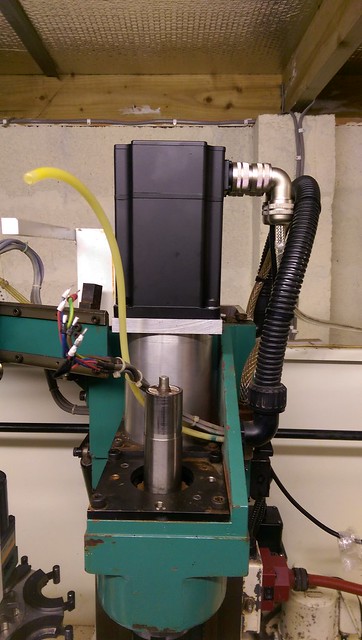

It was then bolted to the machine, and the servo attached-

The whole assembly sits at roughly the same height as the original servo, and the only modification required to the cover, was a hole cut in the side for the servo cable connections, which can be seen in the first photo. I'll get a cover made up for them at some point, but I want to work the machine for a while first to monitor how hot the servo gets, as I may add a cooling fan.

It was then a case of wiring and tuning, which I'll save for another post.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

The Following 2 Users Say Thank You to m_c For This Useful Post:

-

28-11-2017 #44

I know I've been ignoring this for a while, but since the control cabinet build is finally underway, I may as well add it in here.

After a few ideas were bounced around, a couple sketches done, and a mock-up of the controls done, I had a bit of eureka moment. Rather than build from scratch, why not use a bog standard enclosure and modify it to suit. That way much of the faffing around with sheet metal is removed.

The above is a 400x300x150 box. I was originally going to mount everything on the back plate (the bog standard steel one will be getting binned, for a thicker aluminium one), however things were going to be a bit too tight, especially considering I need two 25pin breakout boards for all the required ins/outs, so the computer will quite easily mount on the door (it's easier to run 4 cables between the door and body, than 30+ individual ones if I was to mount the breakout boards). I did briefly consider hardwiring things, but 25pin cables are cheap and convenient, and the breakout boards give easy access for future diagnostics.

All that will connect between this box and the main control cabinet will be the two 25pin cables, and a USB cable. Power will be supplied directly.

Now just to drill a few holes, cut some metal, and do a bit welding..Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

26-12-2017 #45

Since I'm still waiting for the rowing boat to arrive from China with a couple key parts for the control housing, I'm sat here contemplating how I'm going to wire a touch probe in, and it's got me back to thinking about tool changes.

The toolchanger has been working well. I still need to create a recovery/setup screen in KMotionCNC, so I can control it directly from KMCNC, rather than having to toggle things manually should things go wrong (what I really mean is when I screw up the toolchange position, and send toolholders flying in various directions, or jam the carousel against the workpiece...).

Like most CNC programs, KMCNC has a tool table. For every tool you can set the usual offsets, toolID, a description, image file (for if you want an accurate image shown in the viewer) and a Slot.

For a toolchanger, the slot is key. When you request a toolchange in G-code, KMCNC looks for that in the ToolID column, then tells the KFlop to load the tool in the corresponding slot. Off course, it's up to the operator to ensure the correct tool is in the correct slot.

This means you can have multiple tools stored along with their offsets, and when you load the tools into the carousel, KMCNC already knows the offsets, and all you have to do is update the slot ID.

What this also does, is give the ability to control how tool changes are handled.

I've written my changer code, so a request for slot 1-6, results in a fully automatic tool change. Then anything above 6 through to 98, results in a manual tool change, then 99 simply unloads the spindle.

Everything is tracked, so if I go from say slot 3 to 50, it'll automatically unload the tool, retract the tool carousel, and then ask the operator to insert tool 50. Or going back the way, it'll ask the operator to remove the tool, confirm it's been removed, then bring the carousel back out and load tool 3.

Now what's this got to do with a touch probe, other than needing to load it manually?

I'm going to allocate an additional series of slots (probably 95-98), which will get handled differently, and will cause the spindle to align to a known position (index mark on servo) to maximise repeatability, and prevent it from running (you really don't want your touchprobe in a spinning spindle while plugged in...).

Plus I can then force all moves while a touchprobe is loaded, to be protected moves. By protected, it means if the touchprobe gets triggered, all motion is halted, as though you were performing a G31 probing move. It probably won't stop things getting damaged at full speed rapids (I'll probably also add a feedrate override to limit rapid speeds), but it should stop issues like jogging the probe into things stronger than the probe.

Now I'm of to stare blankly at my toolchange code, and think about how I can implement this..Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

17-07-2018 #46

I just added an 80 mm frame 1kw servo to mine. ( just new motor plate required) has 4nm torque . But the motor I had in stock maxes out at 3800 rpm.)

Used a programmable drive to get the indexing spot on for atc alignment.

Original motor and drive were perfect , but for the life of me I couldn't get it to index correctly ( home) due to macro loop 10ms latency.

https://youtu.be/MGVGbKunn5Q

-

17-07-2018 #47

I've also got a noisy bearing in the spindle. So il be referring to your other post re this. Do you by any chance have the bearing numbers required?

And roughly how warm does the main casting on yours get when running? Mines pretty hot after a few minutes at 3000 rpm. - presumably the worn bearing :-(

-

17-07-2018 #48

-

The Following User Says Thank You to andy_con For This Useful Post:

-

17-07-2018 #49

is that 7208ba ? angular contact bearing

are both bearings the same?- i presume there is just 2? - to be honest- not researched it properly yet

-

17-07-2018 #50

-

The Following User Says Thank You to andy_con For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Denford Triac - Help

By mikeadams1985 in forum Denford MillsReplies: 1Last Post: 12-01-2017, 10:06 AM -

FOR SALE: Denford Triac CNC PC

By ricey3 in forum Items For SaleReplies: 6Last Post: 10-01-2017, 01:39 PM -

Denford Triac VMC

By fidia in forum Milling Machines, Builds & ConversionsReplies: 6Last Post: 19-08-2016, 08:18 AM -

Help Denford triac p.c.

By mikeulike in forum Denford MillsReplies: 3Last Post: 02-06-2015, 03:59 PM -

WANTED: Denford Triac

By edwardsjc in forum Items WantedReplies: 13Last Post: 20-08-2012, 08:17 AM

Reply With Quote

Reply With Quote

Bookmarks