Hybrid View

-

18-02-2017 #1

I would really just avoid those unsupported gantries like the plague... yes they may be ok with plastics and wood but they still limit how fast you can push it and will limit you in the future as well if you look to do some harder materials. It is not an area to cut costs imo as it's extremely difficult to upgrade or improve it later without just buying a new machine (which is what I ended up doing).

What is your time scale? I'm probably building myself a new bigger CNC over the next couple of months and the barebones X6-2200L mechanics would be up for grabs once I've done the machining I need to do for you to go to town on with your own electronics. That's like your generic 6040 but with proper profile HG20 type linear rails.Last edited by Zeeflyboy; 18-02-2017 at 01:40 PM.

-

16-02-2017 #2

Hello Jack, you've obviously done your homework on that stuff, and your part/design/method sounds to be even quite elegant.

Re injection molding, tooling should fit in a $5k envelope I would have thought, especially if your 'half shells' can be a mirror of each other, i.e. a single part.

Regards, Jono

-

The Following User Says Thank You to jono5axe For This Useful Post:

-

30-03-2017 #3

Is it worth paying £735 more for the X8?

X6

(X)355×(Y)510×(Z)85mm

57BYGH76-3A steppers

X8

(X)565×(Y)770×(Z)85mm

60BYGH86-4.2A steppers

Controller wise, the X6 uses Mach3. The X8 has an embedded system.

Does it still have usb input for Mach3?

The nearly double workspace is tempting...

Just don't fancy only using their hardware controller.

Thinking about it, £735 is a lot... Never mindLast edited by JOGARA; 30-03-2017 at 10:14 PM.

-

31-03-2017 #4

Bigger is good, if you need the space...

Bigger also however means less rigid for the same given design (as is the case here), so if that space isn't going to be used then it does have a negative aspect to consider.

I'm sure they could supply the X8 with the black control box if requested.

-

14-05-2017 #5

Desperately need a way to set offsets on X and Y.

Looked at the Haimer stuff again but even their smallest one is over 100mm long.

The X6 has 85mm of travel in Z so really pushing it I think if I was to get one of those.

Any other options out there?

That TPA2 is still not in stock.

-

20-05-2017 #6

if machining metals then all you really need is a rod of known diameter (e.g. 6mm), then you can use probing to find the edges just like the Z-height probe does.

The downside is that it only works with conductive materials, that's one area where a proper touch probe has an advantage.

-

10-08-2017 #7

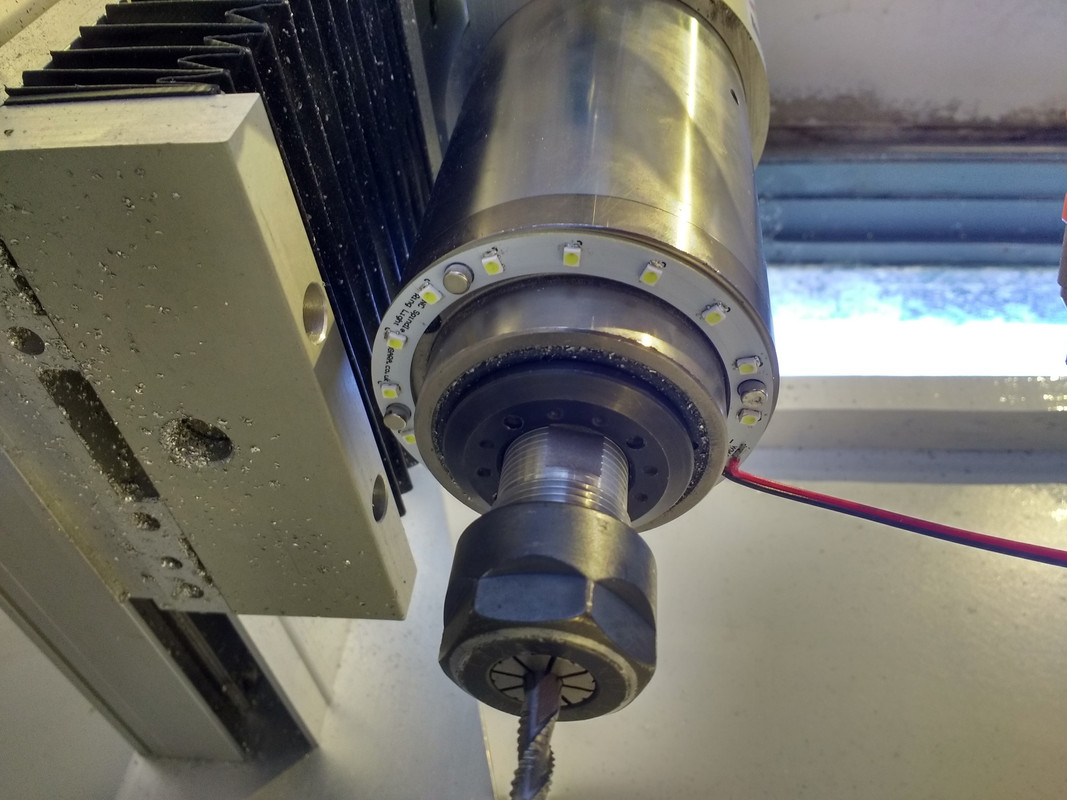

Magnets look to work. IDK about vibrations but never really had any.

I have a few boards left over (12) if anyone wants some.

£1 plus postage I think is fair.

-

10-08-2017 #8

looking very nice.

I did a similar thing with a waterproof ring of LEDs I just bought off ebay, can't say I ever ended up using it much though.

-

05-10-2017 #9

Zeeflyboy, any suggestions on where to start with the TPA-2?

Not been given any docs other than this;

http://kurokesu.com/main/2015/12/30/...robe-to-mach3/

-

05-10-2017 #10

I'm afraid I don't use the same motion controller as you, nor do I use Mach3 anymore... but it should be fairly straight forwards.

Hook it up to the same point that the normal probe goes to, but you just need to go to the ports and pins part to invert the signal mach is looking for as it's a normally closed circuit vs normally open. If you flip over to the diagnostics page of mach you should then be able to see the probe input trigger as you press on the probe tip.

It is definitely worth spending a couple of minutes dialing in the probe tip using a dial indicator before each use - the runout of the spindle/collets results in me getting anything up to around 0.1mm of runout all the way down at the tip which will affect any probing results. Within a couple of minutes of careful tweaking I can get that down to less than 0.01mm

As for probing on mach3 - I've never done it. I think there were some screen sets for mach3 that have probing built in, or you could write a small macro to do it (or use someone else's) but the info is out there if you have a look. Mach4 makes things quite simple with a dedicated probing section built in so I've never had to figure anything out in that regard.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 4 users browsing this thread. (0 members and 4 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks