-

24-11-2017 #221

Last edited by JOGARA; 24-11-2017 at 01:43 PM.

-

24-11-2017 #222That is to hold the collet in place. You have to wiggle the collet in there. I take it you have been doing this, as this might have been your problem.[edit]

Whats with the off center ring on these collect nuts btw?

I have seen it on both this new ball bearing one and my current one shipped with the machine...Clive

The more you know, The better you know, How little you know

-

24-11-2017 #223

I suspect its the way that our CAD systems are 'interpreting' the STL. I know there are some attributes that you can change when you import but not knowing the 'source', we may not know these and this means that the outputted assumption is wrong.

The fact that I wasnt the only person that said this means that there is something not 100%.

What do you use the make the STL?

-

24-11-2017 #224

It's actually to extract the collet from the holder. If you don't clip the collet past the offset lip, then the nut doesn't pull the collet back out when slackened, which can leave you with quite a big headache. Off course not clipping it in also causes uneven clamping, which can lead to excess runout and things not being as secure as they could be...

Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

24-11-2017 #225

-

24-11-2017 #226

-

25-11-2017 #227

It's offset so you can get the collet in/out easily.

If it wasn't offset, you'd not be able to get the collet in/out easily, or you risk the collet popping out the nut when trying to remove the nut/cullet from the chuck.

Balanced nuts are available, if balance is an issue.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

The Following User Says Thank You to m_c For This Useful Post:

-

27-11-2017 #228

Trying to reduce the force that is pulling down the bit.

The thing I changed when it started to happen was that I went from 1mm DOC to 1.5mm DOC.

So I am changing that back (sadly the 1.5mm DOC halfs my machine time which is why I want it).

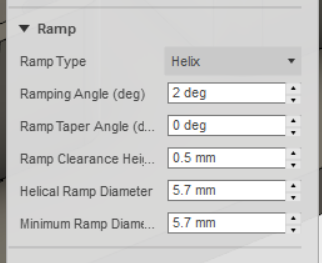

Wondering if the helix is also too much? It sounds nasty when it does it but that could be down to the machine rigidity?

I am tempted to grab a 8mm carbide drill bit and use that to get as far down as possible and use that hole as the "pre drill position"Last edited by JOGARA; 27-11-2017 at 03:39 PM.

-

27-11-2017 #229

-

28-11-2017 #230

Where can I get some oil or whatever to aid with cooling.

Reddit users said my setup for cooling was a bit shit and I have to agree. It is something I have not really looked at improving yet.

They also said my speeds and feeds were wrong for my 6mm roughing bit.

Apparently 12k is wayyyyyy to fast for my feed of 360mm so I am going to try in a bit with 6K and speeding up the feed slowly.

These two things will help resolve my issue.

Thread Information

Users Browsing this Thread

There are currently 2 users browsing this thread. (0 members and 2 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

My bad.

My bad.

Bookmarks