Hybrid View

-

12-04-2017 #1

Downcut bits will avoid that rough edge that you can get on wood like that, might be worth picking some up. Work well on plastics too for the same reason.

I've always found aluminiumwarehouse ok.

I wouldn't over-think the cooling... there isn't that much heat to dissipate. Mine works fine with a small closed loop system (basically a single PC water cooling radiator and pump). Certainly no need to have a 60L system AND a radiator.

If you want to have a big combined cooling system for both your laser and your CNC then sure, why not. Seems to be over-complicating things though.Last edited by Zeeflyboy; 12-04-2017 at 11:14 PM.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

-

13-04-2017 #2

-

The Following User Says Thank You to Boyan Silyavski For This Useful Post:

-

13-04-2017 #3

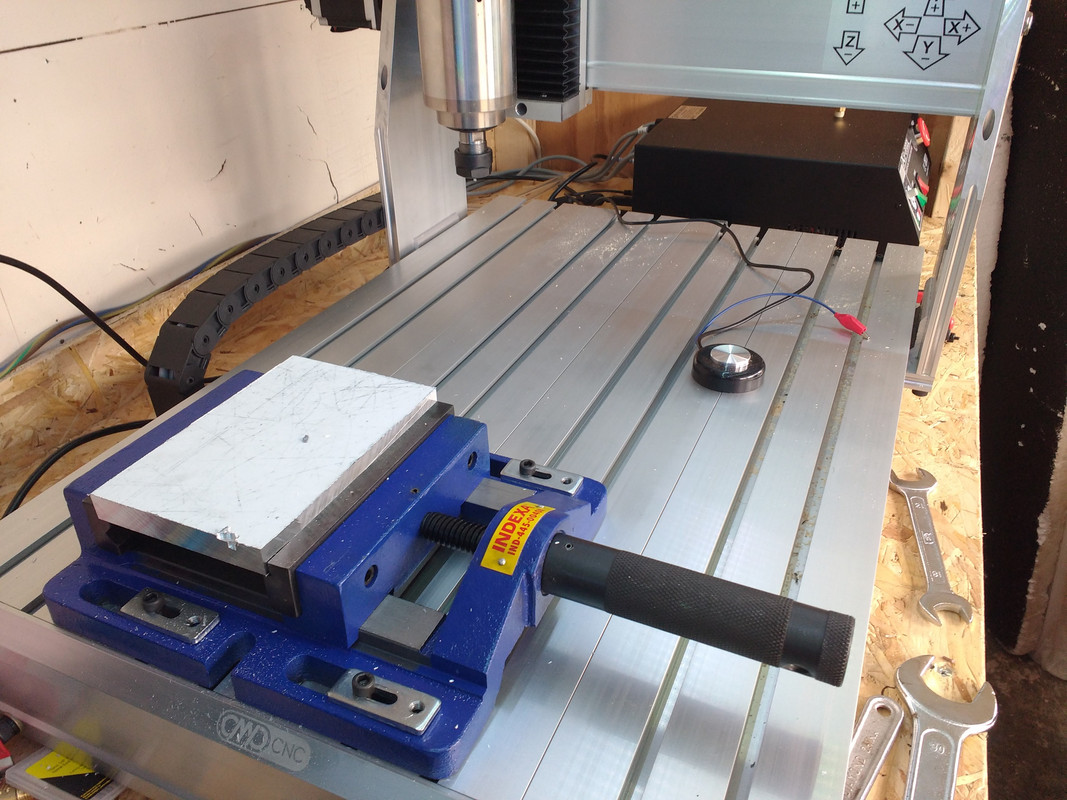

Just got my new vice. Decided against the 2 cheap ones from China that cost £100. Went with a single one for £80 that is built for "light milling". Feels solid enough for what I need.

Holds my 150x100 aluminium perfectly and there is room to put bigger bits in there.

Will work on the mounting of it to the base though.

Only getting 1-2 hours a night to play with it all atm.

Got to finish a load of uni work :/

Also need to work on my speeds and feeds...

-

13-04-2017 #4

looks like it should be fine.

Just beware that your bed won't be level, so bolting the clamp directly to the bed won't give you a level surface either.

Ideally you need to bolt on a spoil board of some description and use the machine to skim it down. That will give you a flat surface to screw the clamp down into.

-

13-04-2017 #5

-

13-04-2017 #6

MDF or similar would be ok as long as you aren't using much coolant. If you have any moisture resistant lying around that is a bit more stable in terms of dimensions and changes in humidity etc but far from essential.

You could also just bolt down a small piece where you intend to put your vice, rather than the whole bed. You would just have to re-skim it if you remove it but that's not a big deal for a small piece like that.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

-

13-04-2017 #7

-

14-04-2017 #8

So this is the case that I am milling out of EcoCast.

These are the end mills I have so far.

3.175mm http://www.ebay.co.uk/itm/1824106825...%3AMEBIDX%3AIT

2mm https://www.aliexpress.com/item/10pc...608.0.0.EJZ3Jx

1mm https://www.aliexpress.com/item/10pc...608.0.0.EJZ3Jx

The case is like 75x60mm so I don't want to carve that all out with a 3.175.

Was thinking of getting something along the lines of a 6mm end mill to do the main hogging out.

What is the max these spindles can take?

I have collets up to 12mm.

Also, where is the best place to learn speeds and feeds? I have been testing these 3mm on a bit of this EcoCast and broke 2 end mills within minutes.

One I accidentally knocked into the work piece. The other because I did not know how to correctly set up the Z in Fusion CAM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks