Threaded View

-

17-04-2017 #11

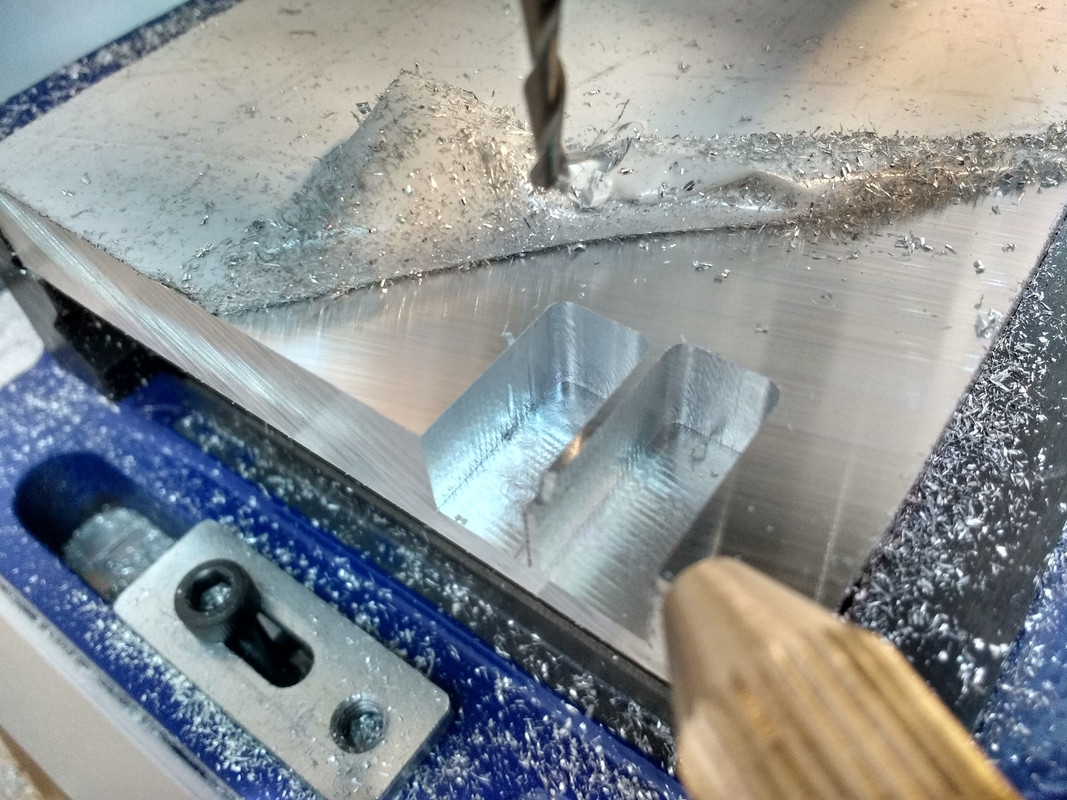

Let it rip at full speed.

Had it weld towards the end causing a few problems. Air pressure was low because it has gone 9PM.

Doesn't look like it stuck to the bit that much. I was able to pick it off with my nail.

Ill try it now at 0.5mm DoC at those rates.

Was at 1mm (went off the rule of it being half the width?).Last edited by JOGARA; 17-04-2017 at 09:13 PM.

Thread Information

Users Browsing this Thread

There are currently 2 users browsing this thread. (0 members and 2 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks