-

25-04-2017 #111

It's only just started doing it?

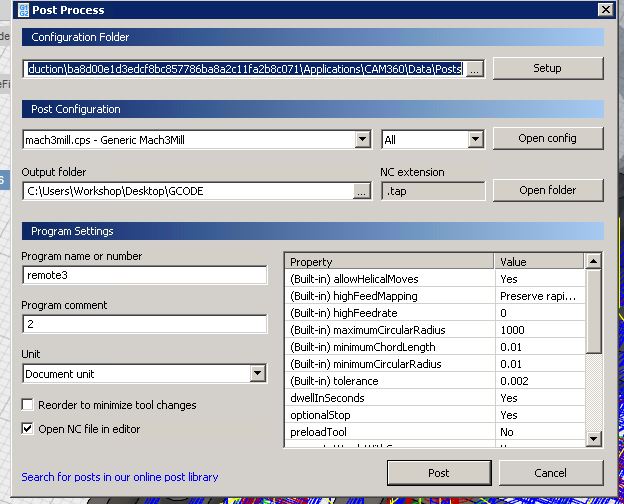

Does the axis travel in mach (i.e. is the Z travelling in the mach "DRO" for the Z axis?). Sure you haven't accidentally picked the wrong post processor?

Does the simulation in fusion work as expected? Quite possible you accidentally set the depth to a top contour if not.Last edited by Zeeflyboy; 25-04-2017 at 08:20 PM.

-

25-04-2017 #112

It worked fine when I did the simple 2D plate of 5mm.

So physically I know the spindle can go down further.

No idea what that is. Will look into it.Does the axis travel in mach (i.e. is the Z travelling in the mach "DRO" for the Z axis?).

Using the stock Mach3 from Fusion.

Simulator works fine. Even goes down the -2mm I set off the bottom of the stock.

The Gcode says the Z to go further,

-

26-04-2017 #113

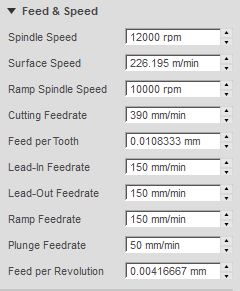

you need more like 22000rpm and 3000mm/min with 3 flute roughing bit at 3mm depth of cut. heavily cooled by air at least. But that are speeds and feeds for very rigid machine or a mill

0.07mm feed per tooth on aluminum? i dont think so, especially on your machine. Lower the depth of cut and look to eliminate any chatter. Or lower feed per tooth to 0.3 lowering your feed speed half.

Just make a video to hear whats going on and we will tell you whats wrong...Last edited by Boyan Silyavski; 26-04-2017 at 06:27 AM.

-

26-04-2017 #114

-

26-04-2017 #115

-

26-04-2017 #116

-

26-04-2017 #117

-

26-04-2017 #118

-

26-04-2017 #119

DDCSV1. It started as a joke, i just had returned the Pokeys57cnc and was wondering what better controller to buy. I have written a lot in the forum about said controller use search function in forum. So at the end it worked so well i did not feel the need to buy the more expensive offline controller i had in mind.

But back to Mach3? God No. Only for special purpose machine where/if i can not avoid it in any other way.

I have basically 0 min downtime last half year in workshop and thousands of things done. I had at least 1 week downtime /if not more/ the previous half year . And the last 5 years if we put together the time i have lost installing windows, Mach3, reconfiguring, boards, plugins, figuring how to make things work...I have lost a couple of months with Mach3, plugins and boards.

-

27-04-2017 #120

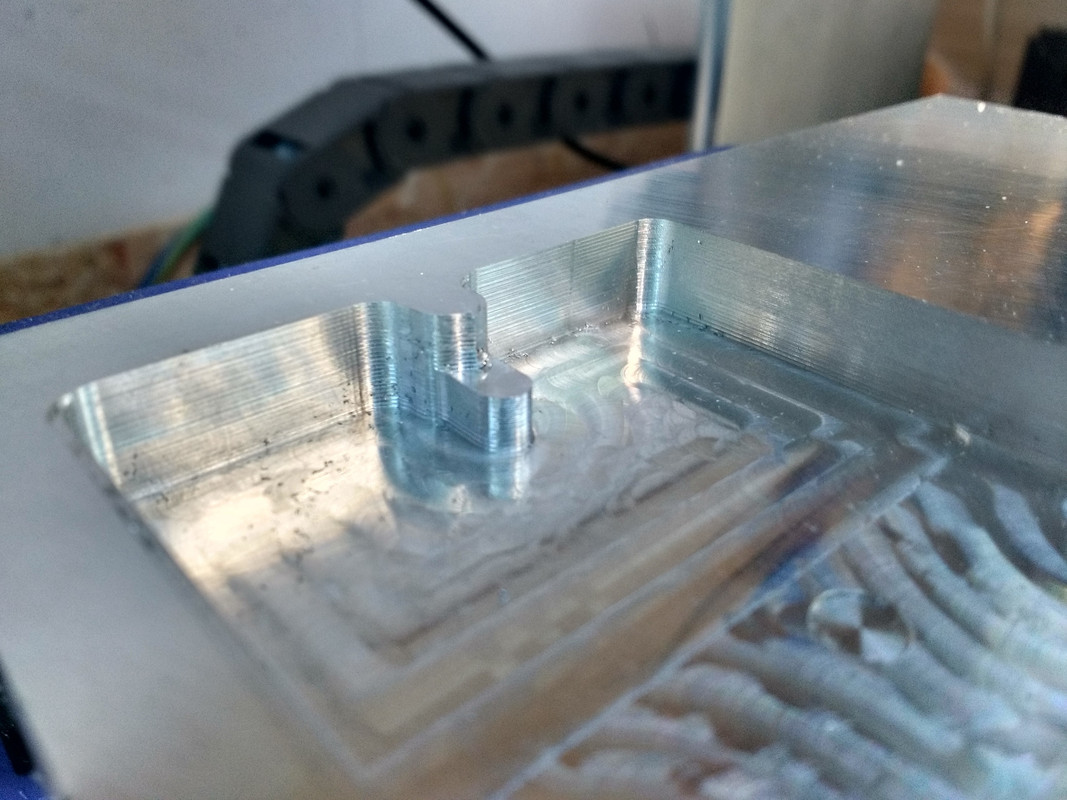

So because I lowered my stickout with the new roughing bit and pretty much all the others, I forgot to lower my spindel to compensate.

Which meant it was hitting the Z limit thus not going lower than 10mm.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks