-

28-11-2017 #231

If you are having these kind of problems now I really dread to think whats coming.

I thought your problem was the cutter being pushed back in the collet not being pulled out? Maybe i need to read back and check that out again. The ramp is fine if anything its to shallow cutters need and want to be worked, sadly you cant do this on a machine like you have. It's just not up to it.

The collet/Nut cutter slippage problem you have. Something is wrong somewhere. These ER systems, although not the best in engineering terms are perfectly adequate for their purpose. Either the collet is out, the spindle taper is out the shank on the cutter tapered. Something is wrong somewhere. It could be you and just lack of knowledge and experience I cant say for definite because i'm not there to see or check whats going on. You are using baby cutters which generate little load and there is no way you need a ball nut for what you are doing. Tightened correctly all should be fine. I cut far in excess of what you are doing by multiple times with ER systems as i have done for years with little issue if ever. It could be a combination of things going on, without someone being there who's knows their stuff its hard to quantify. Also no you should not rough up the cutter or collet or anything for that matter you will solve nothing but will cost your self new equipment when it's buggered up. Plus all this gear is hardened so only serious animalisation would have any effect to 'roughen up'

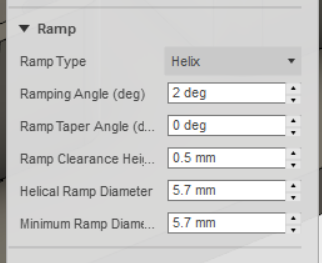

Regarding your ramp. This is the bottom line, rigidity is everything and more so trying to use helical strategy's because it strains the machine in all directing that traditional tool paths don't. Rigidity is something you do not have, I'm not surprised it sounds bad. In Engineering terms, if it sound bad, it is bad. It's bad for the machine its bad for the cutter particularly and will give premature excessive tool wear so be prepared to be buying many cutters.

You have to work within the restrictions of the machine you have. A machine like that is not capable of very much hence why you can not do very much.

I did also pm you about your RFQ but like Chaz i also had no reply after you sent models that were in a usable format. It was only after mailing you i realised this thread existed which did throw another light on the RFQ and why i had no reply most likely. After seeing this thread it's obvious by first choice you want to try to tackle this job on your own and after buying a machine. No one can blame you for that and i admire anyone that has a go. After reading this whole thread through I do kind of think you went in the wrong direction for what you want to do, the quantities particularly is going to be hard on a time vs money factor unless you have zero value of your time and you physically have the time to be spending so long on each part, plus the times scales you quoted per part are very long indeed. Without proper coolant systems and a tool changer on a machine and one that as the ability to actually cut properly, I think you are really up against it in a big way.

I did offer to give you a run through of your parts on the phone via my pm and explain how you could help yourself a lot with the designs and other details with no obligation on your part. It's pretty much impossible to design parts to be economically manufactured without having a good machine shop grounding. This is what i was offering you FOC with no obligation. I have helped and guided a lot of people on this forum over the years with no obligation on their part. But not replying to people that have spent time looking at this for you is a little off. Their time is also valuable. I'm not annoyed, but it raises peoples eyebrows. I'm just being straight with you.

Without intending to offend anyone who may have advised on this job. I can't go back and read every post to check but things i have noted.

You are using the wrong material. It's expensive by comparison and is not that hard. It cut's fine but it wont help you using tooling plate on this job plus some of it has Anodising problems that you mentioned about some are ok and designed for anodising but you need need to make sure. I don't know why you have chosen tooling plate but you choose the right material for the job not the right material for the machine. The job dictates.

The general process you are using is errrrrrr wrong and long winded. I also have suspicions more is wrong in the background that you have not posted here, especially with the cam side. I appreciate you are restricted by the machine but this again comes down to the time Vs money factor. If you saw your job on a machining center you would wonder why you have been wasting your time and you would see the scale of why you are struggling with this job. 4 tons v what hmm 20 kilos of machine? It's chalk and cheese. Kind of hmm 10 seconds to face a 5 mm cut of a, ally block 3 inches wide and 4 long if that, as a simple and crude example. The difference is, you tell the machine what to do with the part as where your machine is telling you what you can do to the part.

Sorry it's long winded but its observation of the is entire thread being as i have not posted in it so far.

I hope you can at least find a few things that are helpful and sheds a bit of light on things for you.

All the best

-

28-11-2017 #232

Hi Spluppit

Thanks for the reply and sorry for not replying to your quote. I thought I got back to everyone but must have missed out on a few.

To be honest it has been a bad couple weeks, I am a few months behind on this project, moving house next week and my dog has been ill. So this has all been stressing me out.

The bit is being pulled out. Resulting it it cutting too much on the Z axis. My 12mm depth is resulting in 12.6-13mm

Should I try and increase the ramp speed a bit and see if that improves things? I think I am taking everything too general which has resulted in poor performance. That being said, some of the parts I have had out of it have been great.

Predrilling a hole for each case is my best bet then for the rigidity problem?

Again sorry for not replying. Just not running on all cylinders the past couple weeks.

I picked the eco cast on recommendation of it being simple and easy to cut on the machine as well as having decent surfaces that I could use for product surface finish. I have not had a problem with the anodising. Other than my fuckup eary on the EcoCast has taken anodising well. What should I be using on this machine?

I understand a proper machine will joblot all 160 cases in a day or two but I didn't have the money for it.

I was quoted before I joined here around £60 per case. I felt that I could buy a machine and learn enough to make them. It is why I designed the case to be really simple though obviously it has not been as smooth and as fast as I would have liked.

Overall the parts I have had from the machine have been fine. It is just this last issue really that is holding us back.

https://s17.postimg.cc/4hp400lb3/IM...201123_HDR.jpg

https://s17.postimg.cc/f4ix5fe0v/IM...936926_HDR.jpg

I have been advised to lower my RPM and improve the coolant so tomorrow I will get a chance to try that out and see if that fixes the problem.

If not, idk.

Thanks for all the info, I understand it is hard to work out what is wrong when you are not in front of the machine and having some idiot on the other side trying to explain what is going on.

Jack,

-

28-11-2017 #233

For coolant, unless you can get good flood coolant, the next best option is air with a bit lubricant.

The key thing with nearly all machining, is to get chips away from the cutter. Getting chips away is even more critical with aluminium, as it can be very prone to chips welding to the cutter, which is never good and often fatal for the part, cutter of both.

I managed for a good few months machining aluminium with just WD40 and compressed air. I'd set the machine running, spray a bit WD40 on, hit cycle start, then wander back every couple minutes and blow chips of the part, and a little bit extra WD40 if it looked like things were getting too dry. I only used enough WD40 to give a light coating on the part/cutter to help stop chips sticking. If I knew there was a critical cut coming up I.e. spiral in, or deep slot, I'd stay and hold the air on the cutter to ensure no chips built up, and add in a bit extra WD40.

The WD40 does make the chips clump together more and a bit harder to blow away, but the trade off was they were less likely to weld to things.

I eventually made a mister, which removed the need for as much babysitting, but it would still need a bit extra assistance in deeper parts.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

28-11-2017 #234

-

28-11-2017 #235

My current system is one of those cheap bendy hoses with air and "mist".

I have pretty decent air going through it with a tiny amount of regular water and have not had any chip welds.

Probably could do with some sort of coolant fluid or additive in the water though to assist.

Ill leave this public for now, will take down at a later date http://a360.co/2zPSUYP

Thanks

-

28-11-2017 #236

Is the air flow enough to blow the chips well out the way?

Provided it's keeping chips well away from the cutter, then your setup should be fine. Even if you have to give an extra blast occasionally, it sounds like you've got a reasonable setup, and I wouldn't worry.

It might be worth trying some of the misting fluids though. This is what I used to use - http://www.johnnealeltd.co.uk/shopenvirocutse10.htmlAvoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

The Following User Says Thank You to m_c For This Useful Post:

-

29-11-2017 #237

Yea the chips fly miles. I found tiny amounts of water and decent air meant that 99% of the chips left my stock area.

The ones left tend to stick along the walls of my part. Not a massive problem as I then go around with my finishing path and I do that dry (only taking off 0.25mm) and that clears whatever is left from me brushing away the majority of leftovers.

That Envirocut SE10 looks good. I like that it is biodegradable. I am using a tiny amount of coolant as it is so 1L should do me for a while?Last edited by JOGARA; 29-11-2017 at 09:48 PM.

-

29-11-2017 #238

Just tested the machine with 1mm DOC at 6000 RPM and it was fine.

Pushed the machine with a face operation of 100% WOC and only when at 720mm feed it made a bit of noise.

So going to try it on part. Obviously not 100% width.

Will quickly try a couple helix with the new speed and faster plunge.

-

30-11-2017 #239

Just ran the operation and it thinks the top of the stock is +1.7mm

No idea what to do...

Contacted Omiocnc so lets see what they think.Last edited by JOGARA; 30-11-2017 at 02:28 AM.

-

01-12-2017 #240

Re: Finishing and part quality.

First of all please do not think i am purposely going out of my way to make you feel bad or I'm being difficult. You have come a long way since the beginning of your post to actually making parts from knowing very little. You should be proud of that and well done. I have tried to gently explain you are a world away still. It really is not as simple as people think at times as buying a machine and making parts. I did a 5 year Toolmaking apprenticeship and 4 years at college and before that i was still on the shop floor for a year before they were satisfied to put me through the apprenticeship etc. Then you are still not considered accomplished that takes another 5 to 10 years. On top of that i have always been in machine shops and workshops since i was a child and had a natural aptitude for the Job. I hope you can try to see this as more a education rather than criticism.

I do not agree that your parts are fine. Without seeing any images of your finished parts, I said you were using the wrong material and the evidence is those images you posted. I appreciate images can be a little deceiving online but i have seen and taken enough to hopefully know what im looking at. Yes your parts are anodised but that is a very broad use of the term, in the fact they have been dumped in a sulfuric tank with some current and then dyed. But that's as far as it goes. The finish is flat and and one one those images shows very blotchy uneven finish and a lot of surface marks. Cosmetics is as important as the function of the item in today's word if its a product people will see and use. (more so if they are paying decent money for it) I did read about you tumbling or vibratory finishing these parts. There are a ton of variables with finishing which i cant go into here but I feel its the wrong move if you understand the anodising process. (Don't slate me for saying this guys, as i said i cant go into full detail) A quick debur if necessary fine but.. the rest hmmmm. By rights parts like this you anodise off the machine. This is 2017.

Also finding a good anodiser is very hard indeed. I know from loosing thousands of pound to idiot ones out there in past years. With this in mind there could be an element of error from the anodiser as i said good ones are very hard to find. I cant tell categorically because I'm not there to see in the flesh. If your anodiser has not mentioned about the quality of the finish on the part or his anodising don't use him is my advice.

You have taken the path of least resistance (on advice granted) to get to your end goal, sadly it does not work like that in manufacturing. I mean this is the politest way but i get the feeling some of the problems is you don't actually know what you are looking at yourself to decide if its acceptable or not.

The result of the part is only as good as the work gone into it.

These images taken last night are literally bits laying about the workshop and these are scrap for various reasons, finishing being one of them. A lot of these parts are very old indeed most of the anodised parts are anything from a year old to up to 25 years old or so. The bare Aluminum parts are straight off the machine, you can anodise straight off this, no finishing and you will get a beautiful satin jet black uniform finish, of course requiring an anodiser who is not a banana eating Orangutan. I could not find a lot of black anodising laying about, but there are few bits and i'm sure you can see the difference.

I will reply to your other post to me in more detail when i get a chance. Also to mention about the cost you were given of £60.00. If you read my pm you will see i explained that you are making the part expensive, the models are not compete for a start, plus you have now altered one. I said about having a chat on the phone to reduce this cost because i expect typically, the tight rads that are probably not necessary plus many other things that can help. This is why you got a very inflated quote. They looked at the part and glazed over, exactly as i did but i offered help, to help you reduce the cost. They should be no where near the price you have been quoted with a little work to make it easier on the manufacturing. You would pick the parts up tapped holes as well.

Its a package deal, knowing how to machine to design economically to machine economically. You cant learn that in 10 months or so.

Last edited by spluppit; 01-12-2017 at 02:32 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks