-

17-01-2018 #251

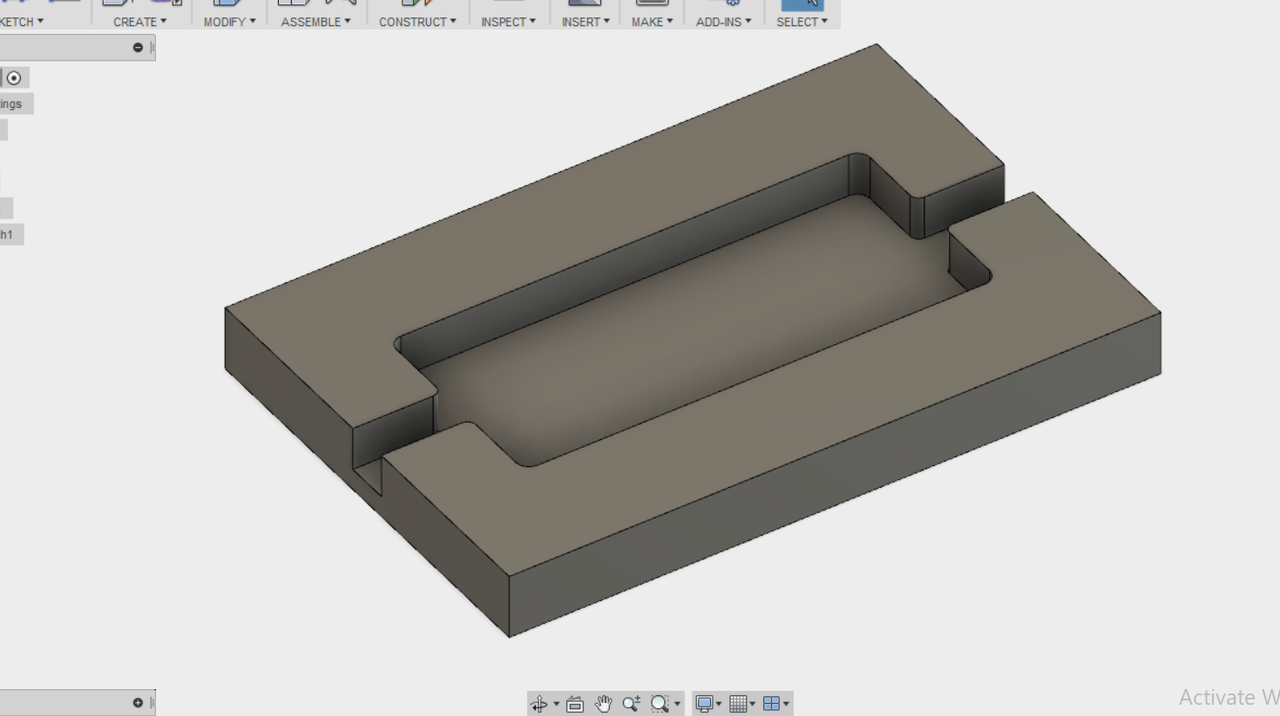

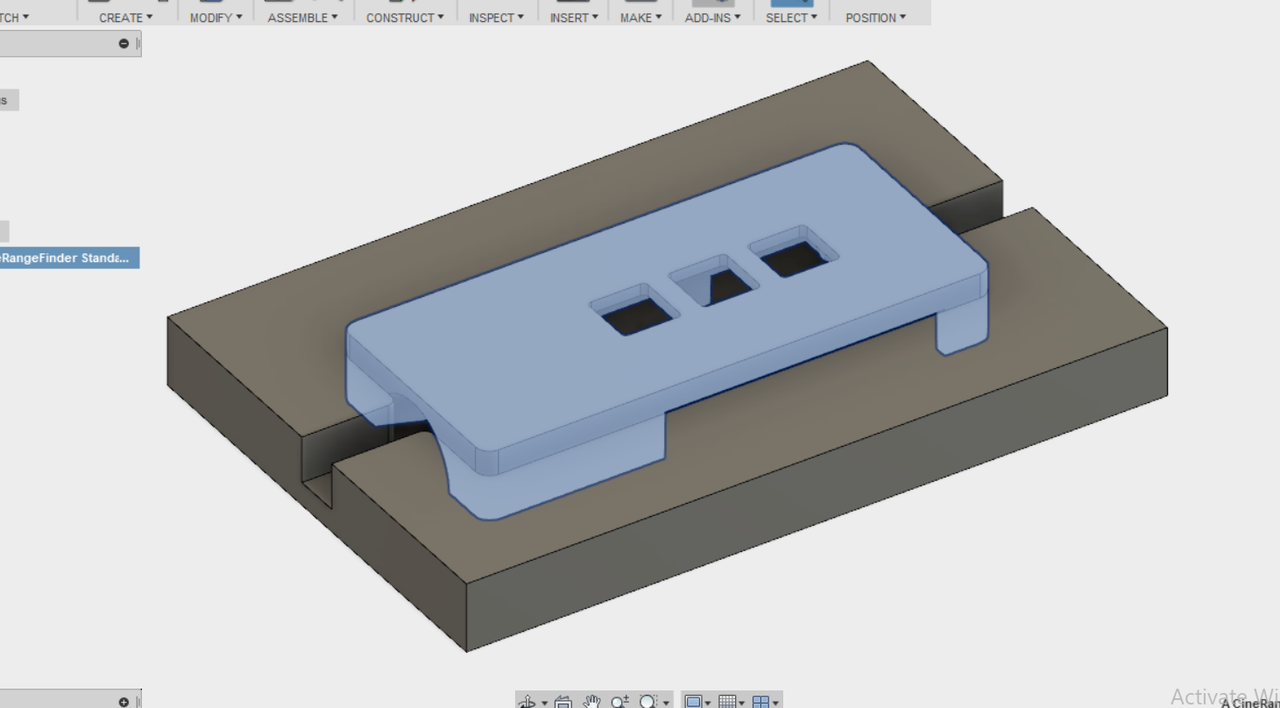

The only way I can think of doing it is to get a bit of 15mm and have my part sit in it.

Then when the vice clamps down, the slight bend in the aluminum locks that part in place. I am talking a tiny tolerance that will not bend enough to cause problems, but enough to grip onto the part.

I'd model it up but my laptop has crapped out on me. Thanks, Windows.

Also, looking to add a solenoid valve to the machine to turn the air on and off.

Fed up with having to reach in and turn it on and off. That and I run the machine and leave it for a bit. If it errors our or finishes the op before Ig et back, would rather it switch off the air.

12v is what the X6-2200L uses on control board right?

-

18-01-2018 #252

-

20-01-2018 #253

Still relying on your vice...

Make that piece (except minus those channels you added to allow it to flex inwards) out of something nice and sturdy - either alu or something like SRBP. Add a couple of threaded holes either side to allow clamps to hold it externally, and maybe two threaded holes internally underneath those cut outs. I would also add a zero reference hole (the probe works better determining zero from a hole probe than from an open edge probe), though I would ream it rather than just drill/mill it.

That then allows you to clamp internally with just a screw and spacer, run your external ops, then switch over to clamping externally with screws and a clamp piece to run your internal ops. Only takes a minute to undo two screws and screw in the other set for switching from internal to external.

depending on what you are doing operations wise, you can also consider the external clamping from both the ends and the sides to allow you to run different operations with external clamping but it doesn't sound like you'll need to.Last edited by Zeeflyboy; 20-01-2018 at 11:57 PM.

-

23-01-2018 #254

I am tempted just to buy a decent machine vice and do it properly..

I think it is obvious that I need a better one anyway when I am doing my first op.

I got to make this easier as I have 30-50 cases to make of each type.

The X6-2200L has 140mm height between the floor and the gantry.

Minus ~5mm for a spoilplate/wonky correction.

Leaves me with 135mm.

Been looking at this, http://www.ymttooling.co.uk/tuscan-s...hine-vice.html

117.5mm to the top of the jaws.

Even if I was to hold parts at the top of the jaws, that is 17.5mm clearance.

The reason I like this vice is that I could probably make the soft jaws really easily.

The lower height ones I have seen all have the triangle jaws which I can't manufacture.

They do sell soft jaws for this but they are £86...

-

23-01-2018 #255

This style of vice is lower - https://www.cutwel.co.uk/work-holdin...-machine-vices

However I've still to find more reasonably priced version.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

23-01-2018 #256

-

23-01-2018 #257

It seems to the ideal vice for what I'd like, but I'm holding of in the hope Cutwel have a promo on them at some point, or until I find something similar in a 5-6" jaw version.

You can make anything with the right tools ;-)Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

23-01-2018 #258

-

24-01-2018 #259

Cutwel had the Gerardi vices on offer in December, I got one. Wish I'd got two. Or thee. Or four

You can set the Gerardi vice up how you want, it doesn't need to have the angle jaws, you can get them with flat jaws, serrated jaws or whatever you want. It's a modular vice and there's a whole tonne of accesories for them. You've still got the issue of the vice bending your work, and in the case of the Gerardi the angle jaws would cause it to bend quite badly (the angle is there to add downforce for pulling the work down to ensure it clamps true repeatedly).

A dedicated fixture really is the way to go here IMO.Last edited by Snapper; 24-01-2018 at 10:51 AM.

-

24-01-2018 #260

What model of those extrusion channel nuts do I need for this X6-2200L?

Thread Information

Users Browsing this Thread

There are currently 8 users browsing this thread. (0 members and 8 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks