Hybrid View

-

26-01-2018 #1

Maybe puts into perspective how feeble the OMIO is in real terms and what you're wanting to make it do

Seriously, put some thought into a dedicated fixture and maybe save yourself a few hundred quid in the process. That big hefty unit is a firm sledgehammer to crack a walnut sort of job.

-

27-01-2018 #2

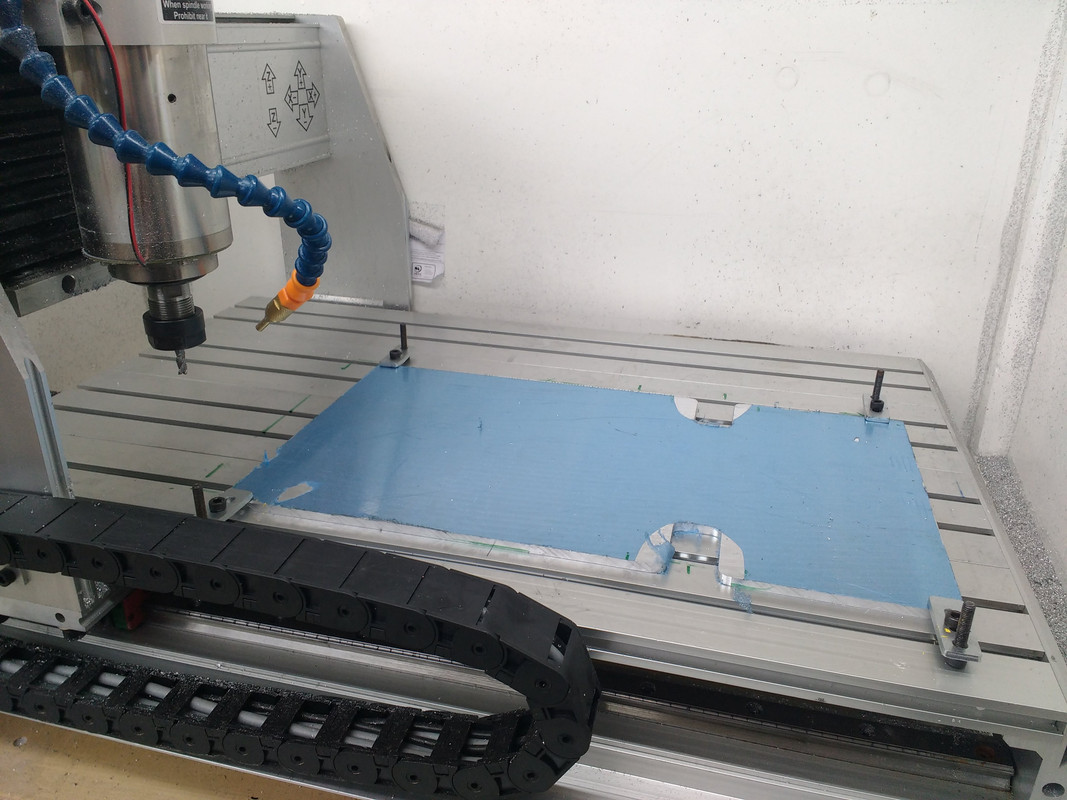

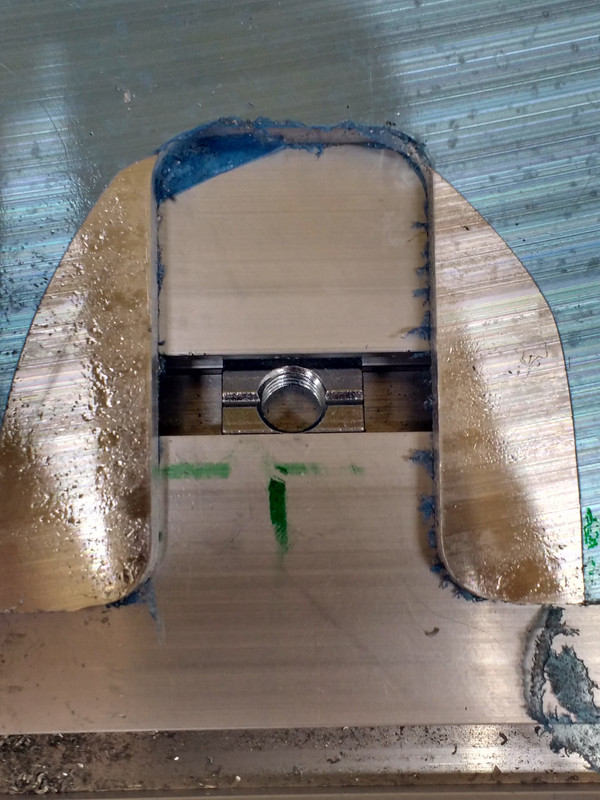

Plate done and vice mounted.

Yes, I could do with larger OD washers. These were all that Screwfix had and the Fixings store I normally go to is now miles away as we moved. That and he closes early xD

The M8 extrustion T-nuts from RS are fine. The bolt is hard to start threading into them but once you have it they really do help.

I think the M6 would have been a bit to small as that would have meant smaller washer too. These things are not going to move.

Z is 0.2mm high at one side of the vice on the Y-axis. X-axis there is no difference.

The Y-axis measurement was taken 350mm from the back of the vice to the front. Most of my parts are sub 100mm so that should be more than fine?

The vice is square or within measurable tolerance with the probe and dial indicator.

It also looks dank af... I get points for that no?Last edited by JOGARA; 27-01-2018 at 07:24 PM.

-

You could shim the vice levelZ is 0.2mm high at one side of the vice on the Y-axis. X-axis there is no difference...Clive

The more you know, The better you know, How little you know

-

27-01-2018 #4

-

28-01-2018 #5

Dam it. I forgot that I have an operation where I need to stand the 105mm tall part on its end to mill out connector holes...

I do have a tiny vice that I could use for this. Might be able to fit it in behind the new vice, will be hard to reach but really is it my only option :/

-

28-01-2018 #6

Great way to firm up the 6040 bed. . . . . . .Replace virtually the entire bed with an enormous vice!

I think it looks good.

-

The Following User Says Thank You to AndyGuid For This Useful Post:

-

30-01-2018 #7

How true is AW's "flat bar" stock?

Like do I need to order the size up of what I want to make it true over 150-200mm lenth of cut?

Thread Information

Users Browsing this Thread

There are currently 6 users browsing this thread. (0 members and 6 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks