-

08-02-2018 #291

-

09-02-2018 #292

Nice. Looks like the vice is giving you much better results so worth every penny if it gets the job done.

For chatter if you're using HSM toolpaths full depth and shallow step over try using a bigger 8mm or 10mm tool. 6mm drill should be absolutely fine, I have absolutely zero problems doing a 6.

-

09-02-2018 #293

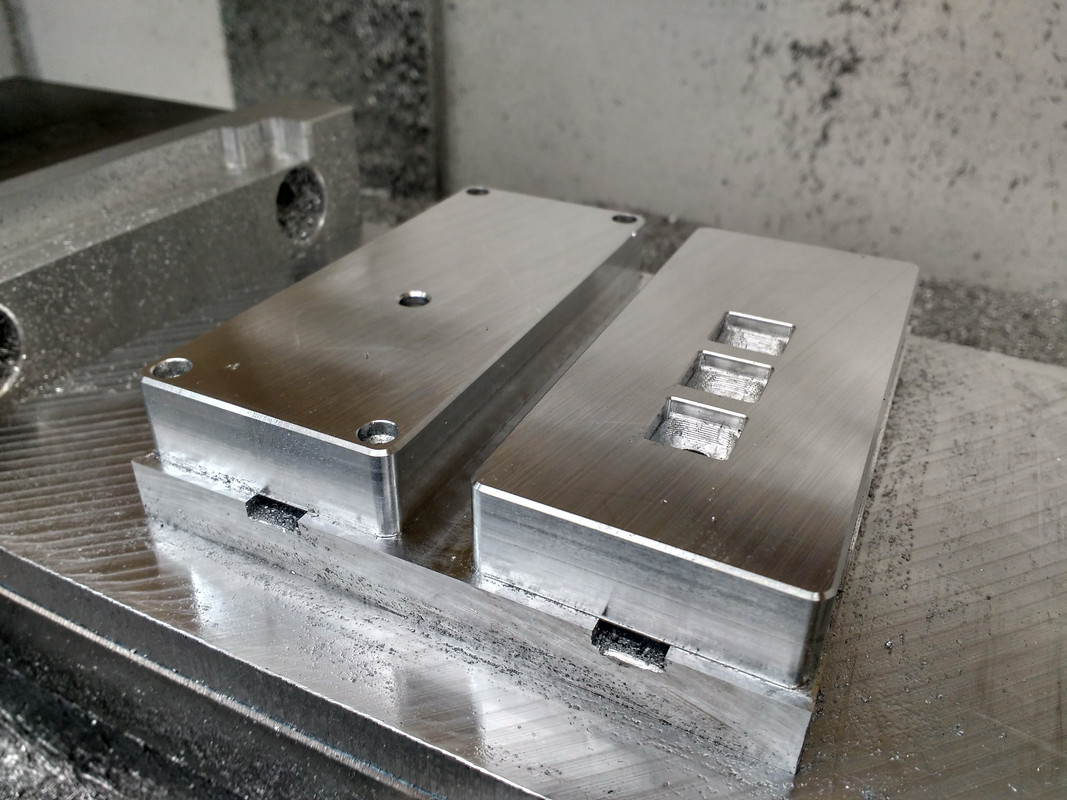

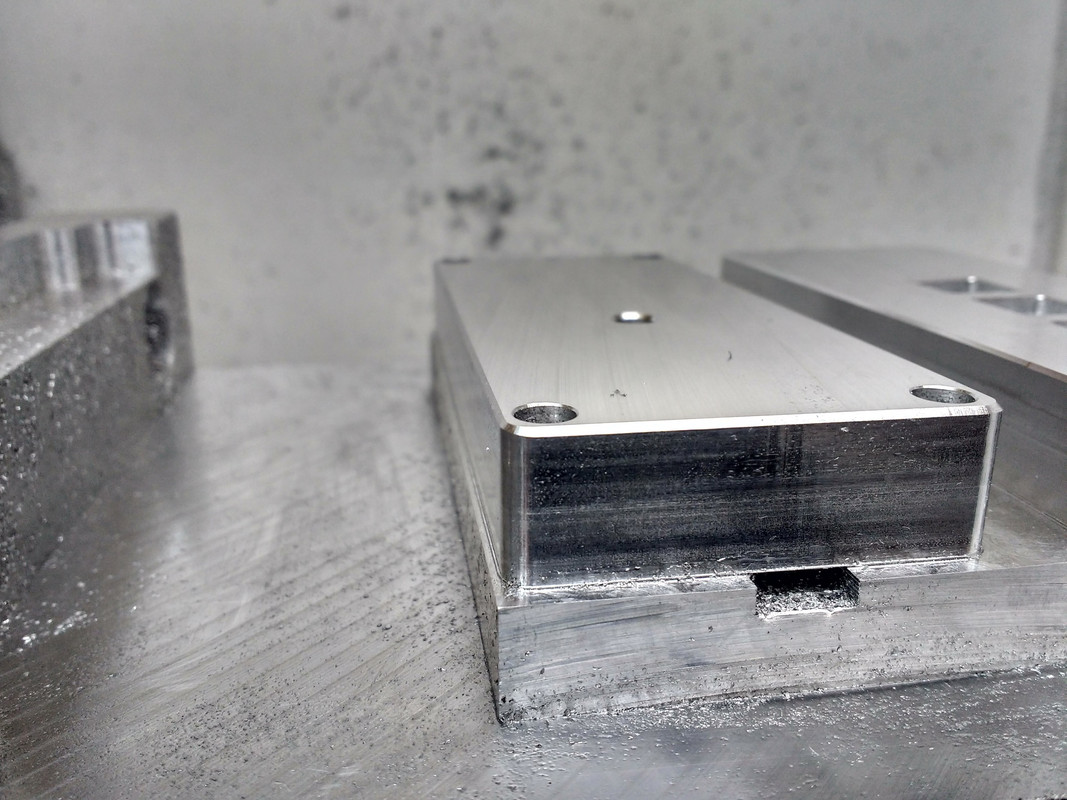

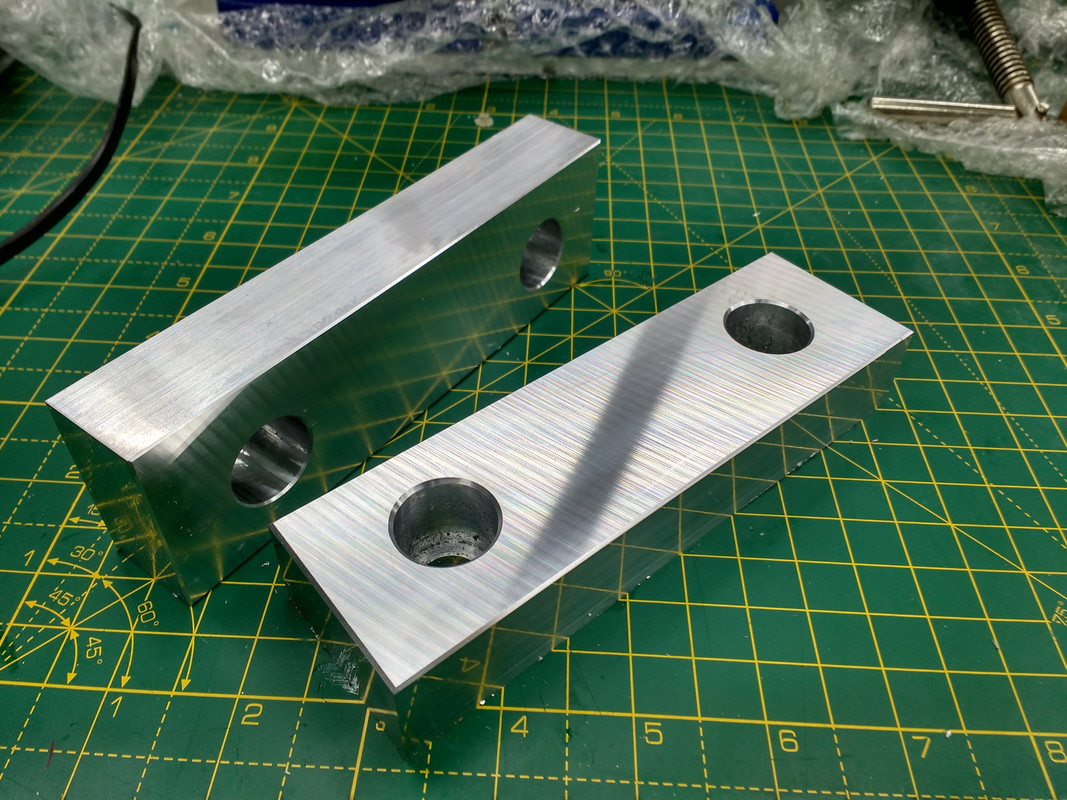

Yea it was a sound investment.

While it sounded like there was chatter, I could not feel anything in the part. Though I did do a contour finishing pass which would have hidden it I guess.

As for HSM, idk if that is what I am doing or not. Not sure what classes HSM. Currently I am taking a DOC that is 50% the width of the tool with a 45% step over.

The only problem I am having ATM is doing a chamfer. For some reason it is quite uneven around the part.

Looks like the part when clamped is lifting a hair but even so, it is low on that corner.

Can only guess that it is not being perfectly probed or the vice is out by a hair?Last edited by JOGARA; 09-02-2018 at 10:55 PM.

-

10-02-2018 #294

If you're using fusion, use the adaptive tool path for clearing metal out. I've cut down to 13mm Doc with my OMIO, between 0.3/0.4mm step over. You can go wider if you're cutting shallower. Better for tool life too as you're using more of the tool than just constantly using the tip.

Skim off the top of the part so it's all perpendicular to your gantry and spindle then your chamfers should be even. A light rub with sandpaper and a quick splash with polish to remove the tool marks and it will look much better than the grainy texture on the top of the extrusion as well.

-

10-02-2018 #295

-

10-02-2018 #296

Should be fine with that. Just play a bit and see what works. One tip, try and square your spindle to the vice, don't spend hours getting it as precise as humanly possible, just 2 minutes with a dual gauge to get it there or there abouts as it will shift out of alignment anyway within about 30 seconds. I do it before every job I want to look half decent. But if you've been jogging into things it's likely to have got knocked well off and that's an invitation for bad chatter.

Also make sure your spindle, collets and nut are squeaky clean for your finishing tools, and if your collet is old and been bashed about, get a new one. They're only tuppence on eBay.

-

10-02-2018 #297

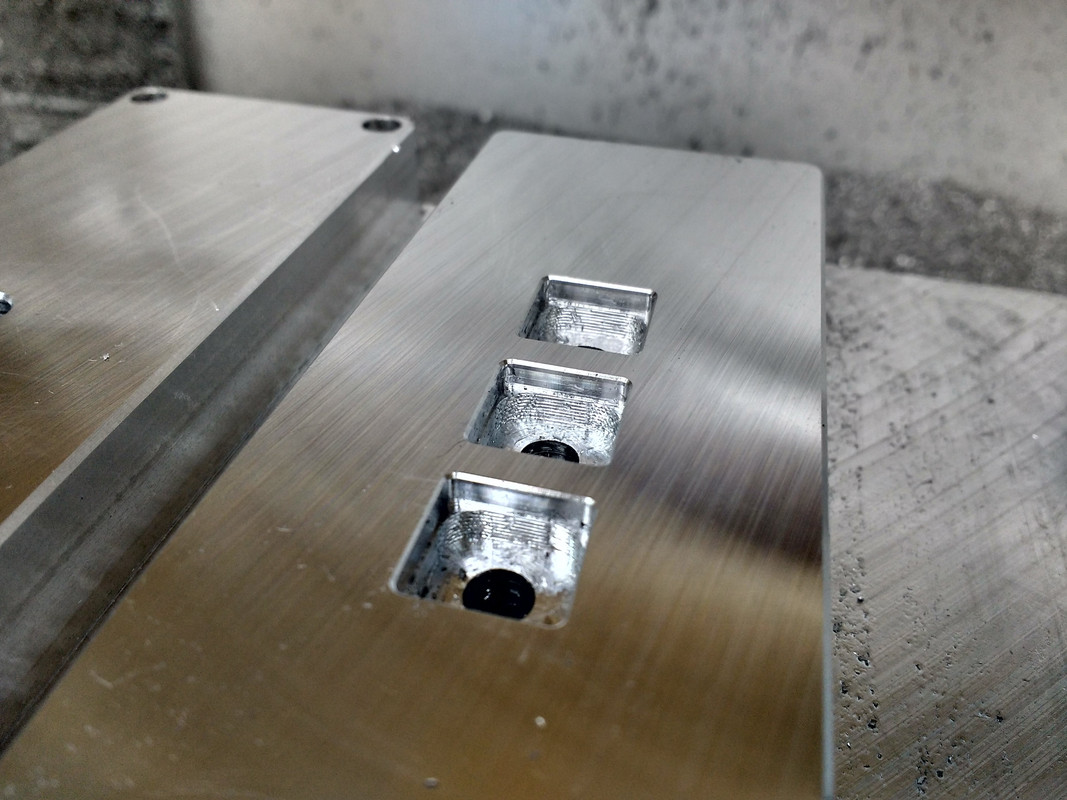

8mm DOC, 0.5mm max stepover.

Cut fine, no noise, looks like I can go deeper.

Going to attempt 1mm. Can always pull it back.

This is much better than the 1hour+ than before. Down to 15mins now :)

The spindle is out but only by a hair. I can feel on the contour pass a slight line going around 2 sides of the part.

I have lowered the contour pass to take 4 depths instead of 2, this fixed that problem last time.

I am also getting this again on the contor. I have a 10mm finishing overlap. But I used default lead-in. I have upped that to 2mm. Hopefully that stops that.

And yes, I forgot to go -0.1mm on the contor pass so there is a bur going around the bottom of the part. The roughing pass went -0.2mm, so I normally set -0.1mm for the finishing endmill.Last edited by JOGARA; 10-02-2018 at 05:06 PM.

-

10-02-2018 #298

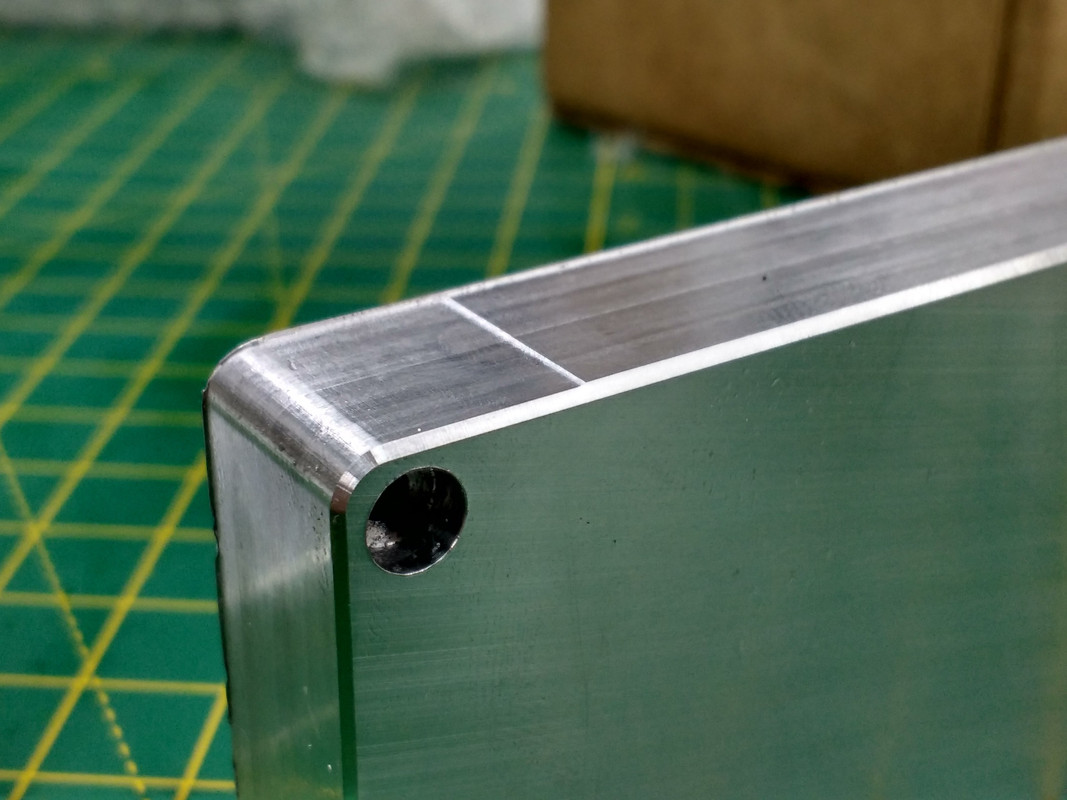

Are you using tooling plate to cut your parts from? That must be costing you a bloody fortune!

-

10-02-2018 #299

-

10-02-2018 #300

This /\

Wanted to reduce my machining time so was faster to have the top and bottom already finished.

That being said, sometimes one side does have marks on it that won't work for a finsihed product.

Most of the time it is only on one side so I mill into that side while leaving the pretty face the to outer face that I see.

What I might be moving towards is bar stock so I can grab it in my vice and not have to glue my stock to a large plate.

Though I like maching the top and bottom at the same time as there are 4-5 tool changes.

If I have ATC then that would not be a problem...Last edited by JOGARA; 10-02-2018 at 06:00 PM.

Thread Information

Users Browsing this Thread

There are currently 2 users browsing this thread. (0 members and 2 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks