Hybrid View

-

28-11-2017 #1

-

28-11-2017 #2

My current system is one of those cheap bendy hoses with air and "mist".

I have pretty decent air going through it with a tiny amount of regular water and have not had any chip welds.

Probably could do with some sort of coolant fluid or additive in the water though to assist.

Ill leave this public for now, will take down at a later date http://a360.co/2zPSUYP

Thanks

-

28-11-2017 #3

Where can I get some oil or whatever to aid with cooling.

Reddit users said my setup for cooling was a bit shit and I have to agree. It is something I have not really looked at improving yet.

They also said my speeds and feeds were wrong for my 6mm roughing bit.

Apparently 12k is wayyyyyy to fast for my feed of 360mm so I am going to try in a bit with 6K and speeding up the feed slowly.

These two things will help resolve my issue.

-

30-11-2017 #4

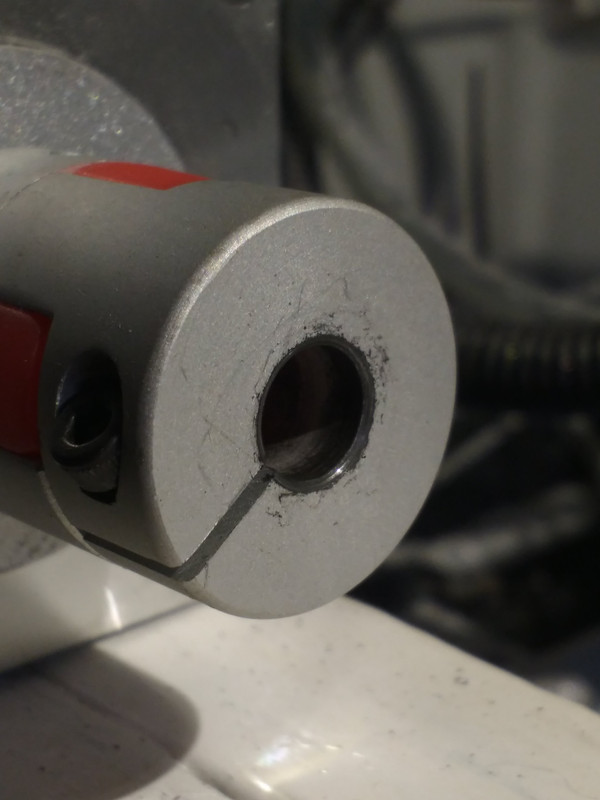

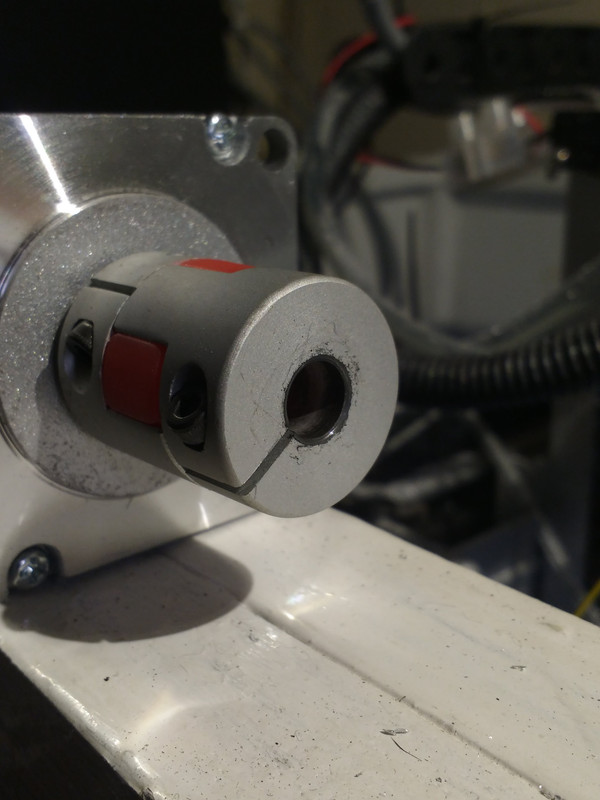

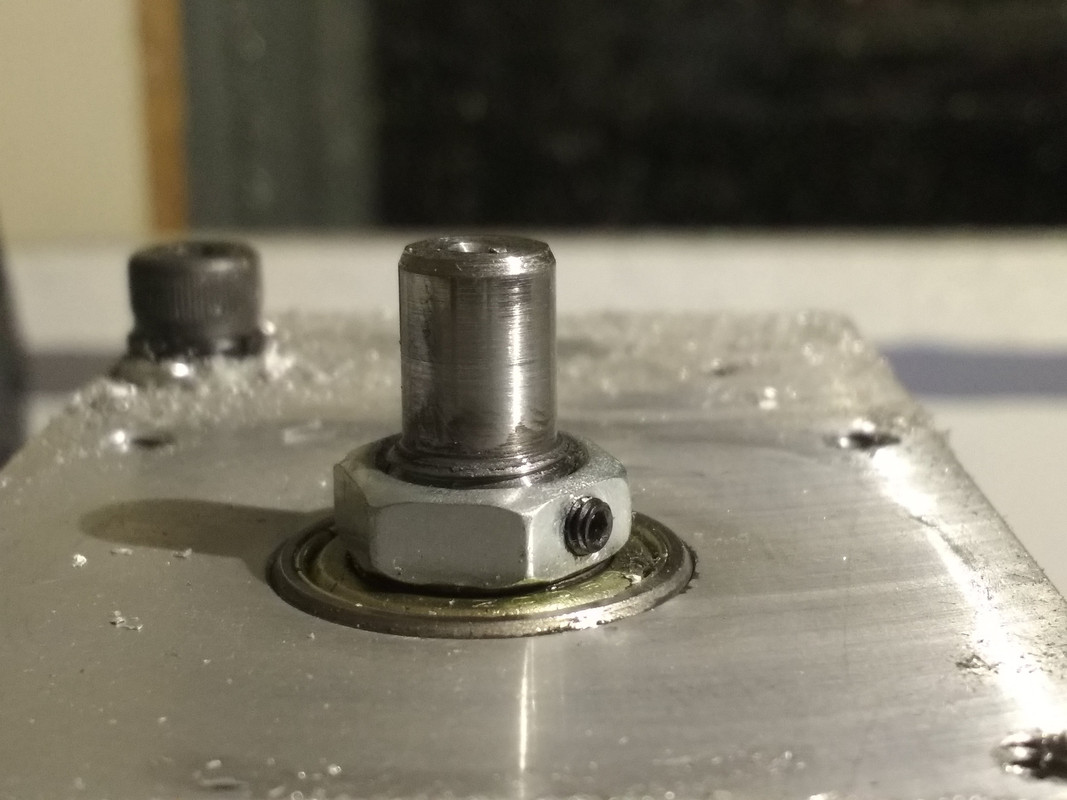

Just ran the operation and it thinks the top of the stock is +1.7mm

No idea what to do...

Contacted Omiocnc so lets see what they think.Last edited by JOGARA; 30-11-2017 at 02:28 AM.

-

01-12-2017 #5

Re: Finishing and part quality.

First of all please do not think i am purposely going out of my way to make you feel bad or I'm being difficult. You have come a long way since the beginning of your post to actually making parts from knowing very little. You should be proud of that and well done. I have tried to gently explain you are a world away still. It really is not as simple as people think at times as buying a machine and making parts. I did a 5 year Toolmaking apprenticeship and 4 years at college and before that i was still on the shop floor for a year before they were satisfied to put me through the apprenticeship etc. Then you are still not considered accomplished that takes another 5 to 10 years. On top of that i have always been in machine shops and workshops since i was a child and had a natural aptitude for the Job. I hope you can try to see this as more a education rather than criticism.

I do not agree that your parts are fine. Without seeing any images of your finished parts, I said you were using the wrong material and the evidence is those images you posted. I appreciate images can be a little deceiving online but i have seen and taken enough to hopefully know what im looking at. Yes your parts are anodised but that is a very broad use of the term, in the fact they have been dumped in a sulfuric tank with some current and then dyed. But that's as far as it goes. The finish is flat and and one one those images shows very blotchy uneven finish and a lot of surface marks. Cosmetics is as important as the function of the item in today's word if its a product people will see and use. (more so if they are paying decent money for it) I did read about you tumbling or vibratory finishing these parts. There are a ton of variables with finishing which i cant go into here but I feel its the wrong move if you understand the anodising process. (Don't slate me for saying this guys, as i said i cant go into full detail) A quick debur if necessary fine but.. the rest hmmmm. By rights parts like this you anodise off the machine. This is 2017.

Also finding a good anodiser is very hard indeed. I know from loosing thousands of pound to idiot ones out there in past years. With this in mind there could be an element of error from the anodiser as i said good ones are very hard to find. I cant tell categorically because I'm not there to see in the flesh. If your anodiser has not mentioned about the quality of the finish on the part or his anodising don't use him is my advice.

You have taken the path of least resistance (on advice granted) to get to your end goal, sadly it does not work like that in manufacturing. I mean this is the politest way but i get the feeling some of the problems is you don't actually know what you are looking at yourself to decide if its acceptable or not.

The result of the part is only as good as the work gone into it.

These images taken last night are literally bits laying about the workshop and these are scrap for various reasons, finishing being one of them. A lot of these parts are very old indeed most of the anodised parts are anything from a year old to up to 25 years old or so. The bare Aluminum parts are straight off the machine, you can anodise straight off this, no finishing and you will get a beautiful satin jet black uniform finish, of course requiring an anodiser who is not a banana eating Orangutan. I could not find a lot of black anodising laying about, but there are few bits and i'm sure you can see the difference.

I will reply to your other post to me in more detail when i get a chance. Also to mention about the cost you were given of £60.00. If you read my pm you will see i explained that you are making the part expensive, the models are not compete for a start, plus you have now altered one. I said about having a chat on the phone to reduce this cost because i expect typically, the tight rads that are probably not necessary plus many other things that can help. This is why you got a very inflated quote. They looked at the part and glazed over, exactly as i did but i offered help, to help you reduce the cost. They should be no where near the price you have been quoted with a little work to make it easier on the manufacturing. You would pick the parts up tapped holes as well.

Its a package deal, knowing how to machine to design economically to machine economically. You cant learn that in 10 months or so.

Last edited by spluppit; 01-12-2017 at 02:32 PM.

-

01-12-2017 #6

Because you are using 6mm cutters from memory, I filmed a very simple job I did a day ago producing some slots. 3 Flute High Helix 6 mm Dim 6.7 wide slot, the difference is this cutter is not a ripper as you are using for roughing out, It would be considerably faster with a ripper but for this job it worked as it was.

One of the examples of this is how important coolant is and you can see what we do in industry, especially in closed slots like this where there isnt a lot of room for swarf

It's not fast and the speeds can be ramped up a fair bit if needs be, but it was adequate for the job in had without any risks. The time i had debured the previous part the one on the machine is done, so speed isnt always everything. My machine is not massively fast as its a solid way machine but that does have advantages also.

https://www.youtube.com/watch?v=RT6XYkOYJHwhttp://

Last edited by spluppit; 01-12-2017 at 02:52 PM.

-

04-12-2017 #7

-

19-02-2018 #8

Wont even drill now without producing that error :(

-

20-02-2018 #9

I am also trying to work out how to add outputs to this USB controller card.

Are the outputs the same, as in pin 1 is OUT1 on the card?

Is it pull high or low too?

-

25-02-2018 #10

Not sure what is going on but it keep losing X machine cords.

My operation has tool changes, I change the tool and set it off the work piece.

I hit run and it slowly goes back to where it stopped the contour or chamfer and then it fucks off somewhere, sometimes crashing the machine...

-

The Following 2 Users Say Thank You to JOGARA For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks