-

20-05-2017 #141

if machining metals then all you really need is a rod of known diameter (e.g. 6mm), then you can use probing to find the edges just like the Z-height probe does.

The downside is that it only works with conductive materials, that's one area where a proper touch probe has an advantage.

-

30-05-2017 #142

I'll try that method and see how well it goes.

Ta

Any recommendations on what I can put in my water cooling to prevent rust?

Not been able to work for 2 weeks and the outlet pipe is going rusty gold.

-

30-05-2017 #143

you just got an open loop?

some antifreeze would probably do the job, and keep the tub covered and out of reach of any pets/children

-

30-05-2017 #144

-

30-05-2017 #145

don't think screenwash has any anti-corrosion inhibitors which is really what you are after.

http://www.carparts4less.co.uk/cp4l/...FUg6GwodLDEB_A

something like that would do

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

-

30-05-2017 #146

-

31-05-2017 #147

Wondering if I could get some feedback on this cabinet design.

Would love to make it out of Aluminum profile but that is like £300-400 for a full cabinet.

So making it out of wood and painting it with water resistant something...

Main reason why I am going for a full tower is that I need the machine enclosed to lower the mess it creates.

That and it takes up a load of desk space that could be better used if the CNC was in a vertical form.

I have added a catch pan draw that will allow me to blow/brush off chips from the machine and parts and they can all land there to collect.

It will be water tight tough I might add a slop to it with a drain to allow the coolant to drain out as it builds up, allowing me to reuse some of it once filtered.

Windows/doors to the right are the main access to change things on the machine like stock, vice etc as they both open out.

The front window/door is to access the machine mostly while running. Which is why I am considering making it slide up so it is easy to get to the part being worked on.

The left doors are just for servicing.

The back is fully boarded with 12mm wood to add strength to the build.

Underneath is enough room for control box, PC tower, spindle cooling tank, fresh coolant and coolant collection.

The two beams going from left to right are for the CNC machine to sit on. They will allow for the waste and coolant to drip down below the machine into the catch pan.

It also pulls out to allow one to remove waste.

Last edited by JOGARA; 31-05-2017 at 02:05 PM.

-

The Following User Says Thank You to JOGARA For This Useful Post:

-

03-08-2017 #148

Been a busy few months.

Ordering a lot of stock aluminum for the product housing.

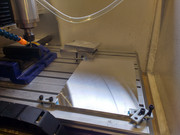

The unlevel bed started to show up in the finish if the housing so a bit of 8mm on the bed and faced it off about 1mm down. Oddly not that much difference in it so thinking the vice might be causing the unlevel finish. Might make some soft jaws that custom fit the housing anyway so that will make it level.

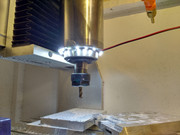

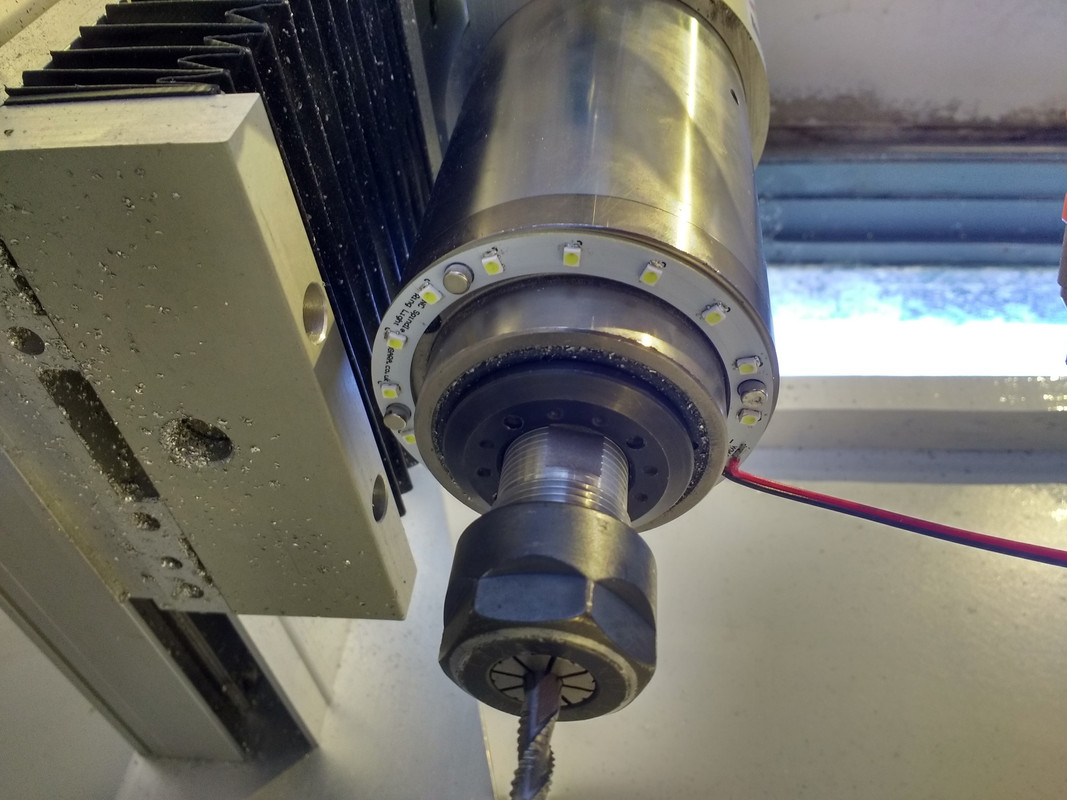

Also as I was ordering a load of circuit boards I whipped up this little ring light to fit the 80mm spindle.

These photos are just testing it but I am going to try and mount it using neodymium magnets.

I know the motor is using magnets so they might not work too well but there looks to be a decent amount of steel there so should be okay.

Take 12v at around 150mAh. Not the brightest in the world but I designed them to help improve lighting on the workpiece not light the whole thing.

I also made my cabinet.

Didn't make a whole stand like I designed a month ago. Don't really have the space for it so made a table top cabinet.

The base is actually from a Ikea bookcase. No idea where it came from. Think it was a shelf we ordered but was the wrong size, but it was perfect for this use...

The sides are just that regular chipboard? from B&Q. Everything painted with 3-4 coats of gloss. All joints filled with silicone.

The base is slanted to allow water (coolant) to run down into a small rain gutter.

2 doors on the front using 5mm acrylic.

No roof yet, will make one eventually as the noise comes from there and chips when blowing fly out of it xD

Last edited by JOGARA; 03-08-2017 at 12:52 AM.

-

10-08-2017 #149

Magnets look to work. IDK about vibrations but never really had any.

I have a few boards left over (12) if anyone wants some.

£1 plus postage I think is fair.

-

10-08-2017 #150

looking very nice.

I did a similar thing with a waterproof ring of LEDs I just bought off ebay, can't say I ever ended up using it much though.

Thread Information

Users Browsing this Thread

There are currently 16 users browsing this thread. (0 members and 16 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks