-

08-07-2017 #1

is it dependant on cfm from compressor

at what psi / bar do you run a plasma

can you hold the material to be cut on a bed of nails type affair using nuts and bolt

could you then magnetize the bolts

m4 bolts @ 3'' sticking up through a threaded plate at 2'' spacing, 'just' laying in the trough

do you 'have' to use a machine torch

is mach 4 now good for the novice

are more people going servo - even at 200 to 400 watts

are there simple i.e. beginner set up video's for mach 4 compliant controllers

IF running ball screw gantries on a plasma, is there a beneficial screw pitch to get the speed up

I am going to buy

two 1000mm

one 900mm

and a 300mm

bosch rextroth gantries

I suppose I am going to link the two 1000mm gantries with a rubber belt

do I go for a 50mm round 24 tooth htd 8mm pitch pair of gears and belt

what about collision break away attatchments for the torch, is there an off the shelf option

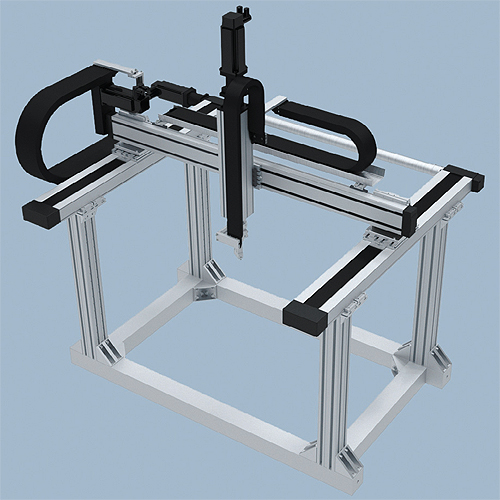

so in short, a 1000mm by 900mm bed using off the shelf gantries

200 watt Panasonic minas a4 servo's and drives

DON'T KNOW AS YET WHAT CONTROLLER

have mach3 license and sheetcam

this is what I am after but its belt drive, I am going to use second hand ball screw versions

bit like that buy I want it so the water trough is sitting on the floor and I can have a top on the table

so I have to link the x drives with a belt - 'that maybe the determining factor'?

any one use the stuff?Last edited by nobby; 08-07-2017 at 01:02 PM.

-

09-07-2017 #2

I'll go for a couple of these. Are you asking about a straight forward tank or with the ability to raise and lower the water level via compressed air? Compressor running at about 8 bar should do. The air should be oil and water free. Bolts sticking up should be ok as long as the plate you are cutting is reasonably flat. Just make sure the tops of the bolts are as level as possible. A machine torch would be required. A magnetic torch collision device would be relatively easy to make depending on how your are going to do the initial height setup for the plasma. If you are using arc voltage control for cutting height control then do you need an initial height set control as well? If not and you are going to set the height at the start and either manually adjust it or let it cut then the collision device is easy enough. Two machined plates with magnets embedded in them and a couple of pointed grub screws through from the back plate to locate the front plate the torch is on.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Do you need to water cool erhm a water cooled spindle?!!

By HankMcSpank in forum Generic Chinese SpindlesReplies: 18Last Post: 02-10-2013, 09:59 PM -

Cooling a water cooled spindle, without pipes everywhere & huge water tanks/buckets!

By HankMcSpank in forum Generic Chinese SpindlesReplies: 17Last Post: 18-09-2013, 06:32 AM -

Speeds and feeds deep drilling

By Razorab in forum Sieg Milling MachinesReplies: 13Last Post: 10-02-2013, 09:00 PM -

How deep can i cut MDF?

By MrWiz73 in forum Machine DiscussionReplies: 6Last Post: 24-08-2011, 10:38 PM

Reply With Quote

Reply With Quote

Bookmarks