Threaded View

-

09-06-2018 #11

Hi everyone, and thanks for all your advice so far.

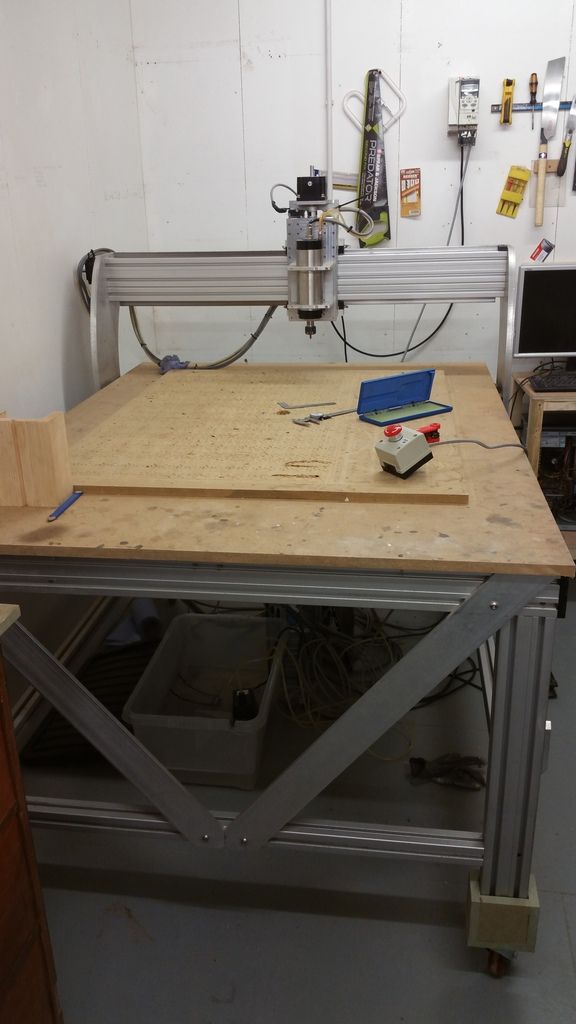

Whilst planning my build I have still been checking on the used machines on ebay etc. One came up that looked sturdy and was about the size I wanted (actually a bit bigger than I was planning). Anyway I made an offer and now this lives in my workshop.

I put those wheels on so I can move it on my own, I might leave them on but if it causes problems then I can take them off once its fully installed. They are just sort skates that slip on to the frame.

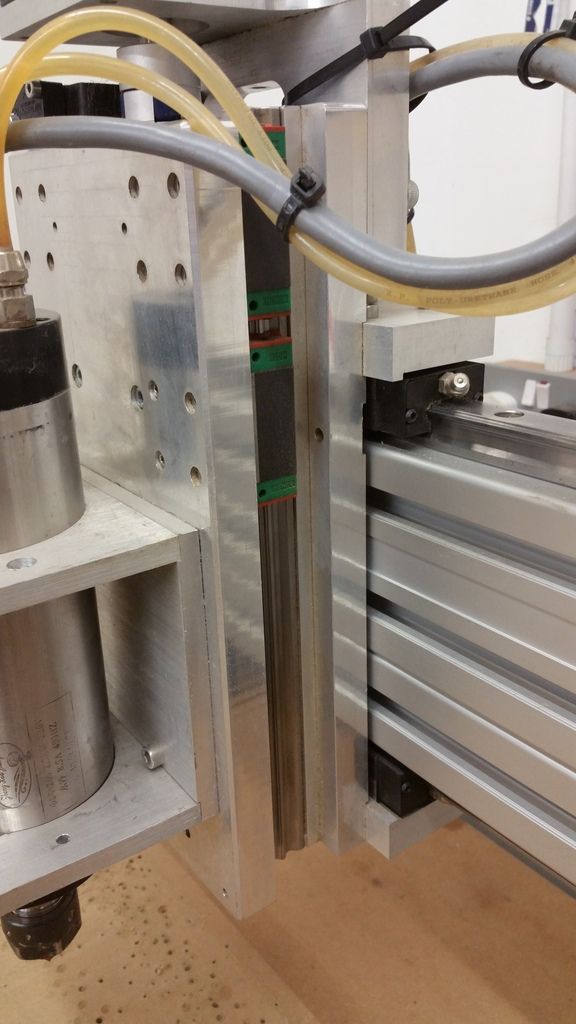

It has Hiwin 15mm on the Y axis with central 25mm ballscrew

Hiwin 20mm on the X with 25mm ballscrew

Hiwin 15mm on the Z with 16mm ballscrew

Motors are nema 34 size not sure about strength of them

There is homing or limit switches on the x and z but none on the Y.

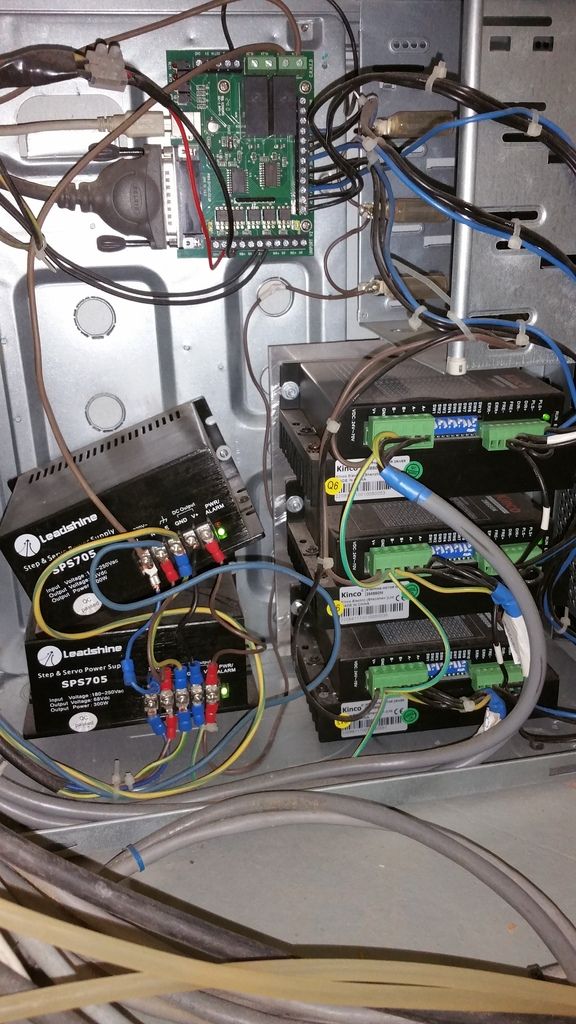

The electronics live in an old PC case

A Breakout board uniport from diycnc

2 leadshine SPS705 power supplies

3 Kimco stepper motor drivers

The frame is mostly 45mm by 90mm extrusion and the x and z plates are all 20mm.

The spindle is 2.2kw chinese watercooled, it is controlled by this thing.

However it only seems to be controlled by the small dial and switches at the bottom which adjusts the speed but reads in hertz so I will have to do some maths on that. The other buttons on the removable control bit don`t appear to do anything.

So now my new mission is to get this thing working perfectly so I can learn about everything and get productive, I would still like to build my own but this might be a better use of my limited time at this point.

I got the machine running with the PC that came with it mach3 was installed as well as Vectric aspire (which i never got a chance to use). I managed to get everything jogging nicely using mach3 so I know that the power supplies and stepper drivers are all working at least.

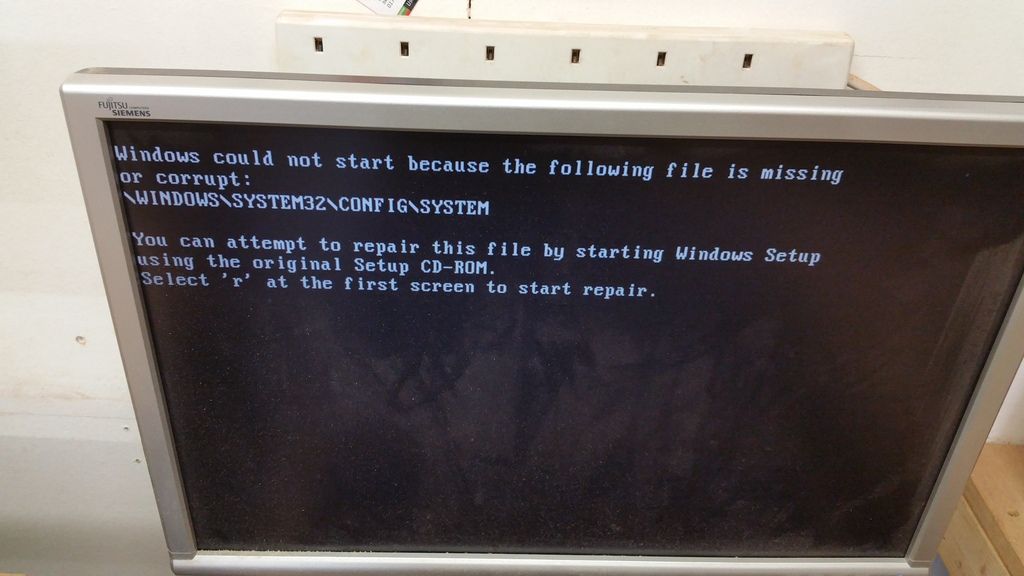

However before I managed to get much further, I was trying to establish a home position etc. The Machine stopped jogging and didn`t want to respond. The only evidence of an issue was a red light on one of the sps705 power supplies. So I rebooted everything and then I got this unhappy sight.

So I am a bit stuffed for now. However when I turn on the system all the LEDs in the control box are green again (not sure exactly what this means but I am looking at it positively).

I will try to recover the system with a usb boot recovery if I can ( it is running XP I think). If not its new pc time.

This leads to a question (first of many) .

Should I stick with an old system with parallel port and 32 bit or go for a more modern and thus hopefully reliable windows 8 or 10 system ?

I am thinking of a small media box type pc with maybe fanless design for less dust issues or even a laptop.

As I understand it this would require another board to communicate with the PC via ethernet or USB and the parallel port on the breakout board.

Any recommendations on best method for this?

Computer problems aside I started cleaning up all the ballscrews and tracks etc. I cleaned up the x axis ballscrew and track with some boeshield and it came up nicely.

What is the best grease to use for the ballnuts and carriages ?

The bigger 20mm carriages have grease nipples but the 15mm ones don`t have any. How do you grease these ones.

Also I have noticed that the bearing on the drive end of the X axis is a bit clicky and needs changing the same bearing on the Y is suspect too. Z is fine.

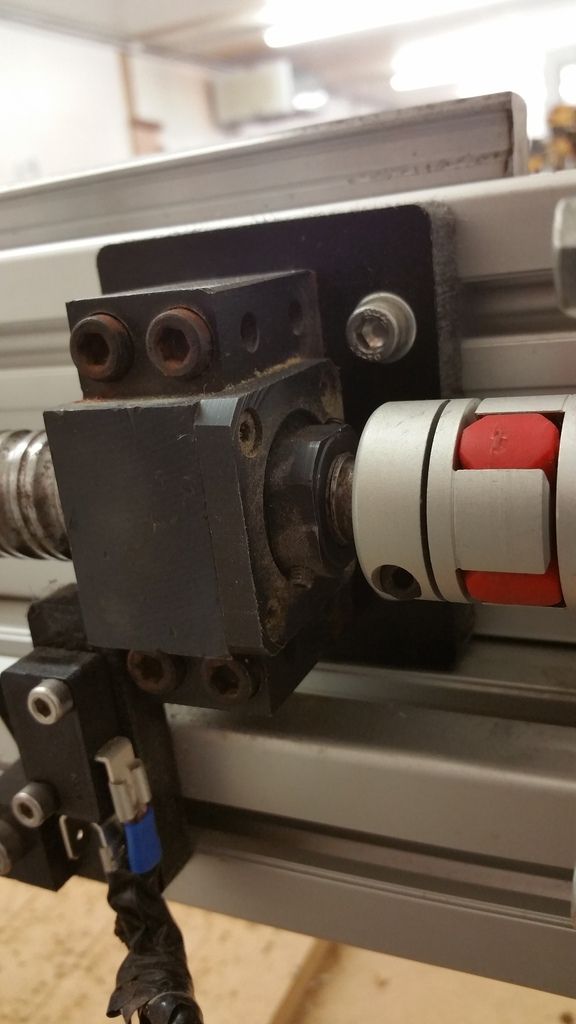

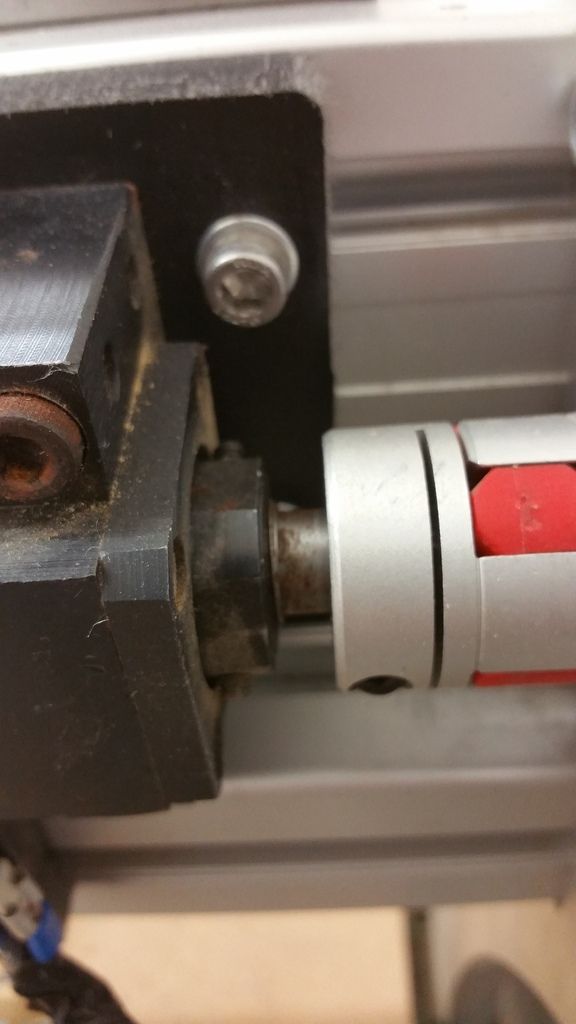

The blocks are these ones

The shaft has been turned down to 12mm just after the bearing before the coupler, the bearing block is 26mm wide and about 70mm high. does anyone know the name or type of this block bearing?

Can the bearing be replaced easily (ie without a press) or do I need to get the whole block?

What water/ coolant is best for the spindle, it has a small fishtank style pump. I am just using the same water (demineralized apparently) that was already in it. But I will be making a better tank arrangement before i use it again.

Oh and can you buy those green grommets for the rails separately? the holes were filled up with dust.

Thanks for reading all that.

Ollie

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

can someone please help with hole dimensions

By reefy86 in forum SolidworksReplies: 38Last Post: 20-02-2016, 12:44 PM -

Hole Radius

By benkat in forum Machine DiscussionReplies: 0Last Post: 03-03-2014, 05:29 PM -

SBR16UU Centre hole.

By cambesol in forum Rails, Guideways & BearingsReplies: 3Last Post: 25-11-2013, 05:39 PM -

HELP! Problem drilling 2.39 dia hole in Ali casting

By woolley2002 in forum Machine DiscussionReplies: 4Last Post: 04-09-2013, 09:06 AM -

6mm shaft to 6.35mm hole?

By JuKu in forum Metalwork DiscussionReplies: 3Last Post: 15-12-2012, 02:29 PM

Reply With Quote

Reply With Quote

Bookmarks