-

09-06-2018 #11

Hi everyone, and thanks for all your advice so far.

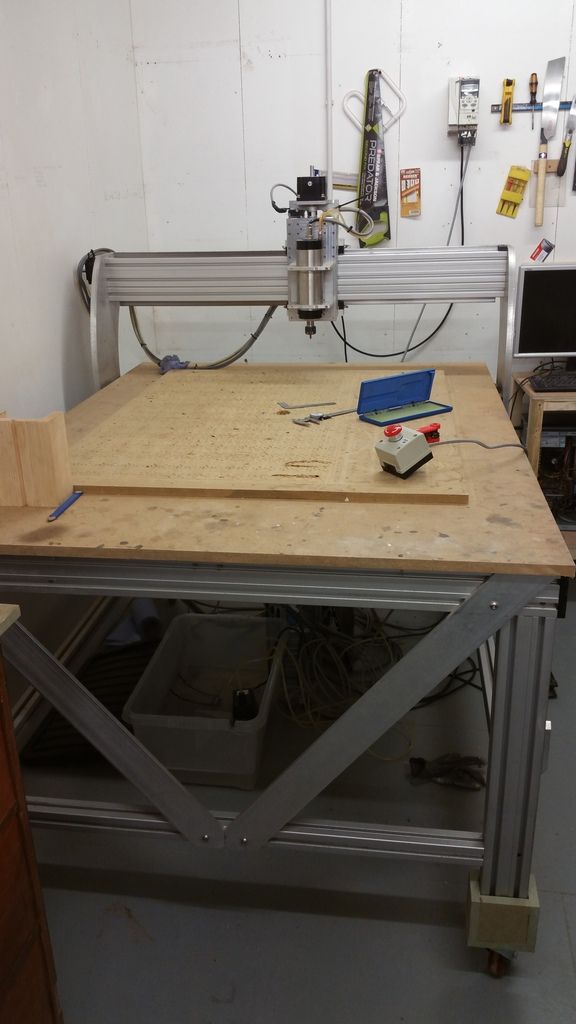

Whilst planning my build I have still been checking on the used machines on ebay etc. One came up that looked sturdy and was about the size I wanted (actually a bit bigger than I was planning). Anyway I made an offer and now this lives in my workshop.

I put those wheels on so I can move it on my own, I might leave them on but if it causes problems then I can take them off once its fully installed. They are just sort skates that slip on to the frame.

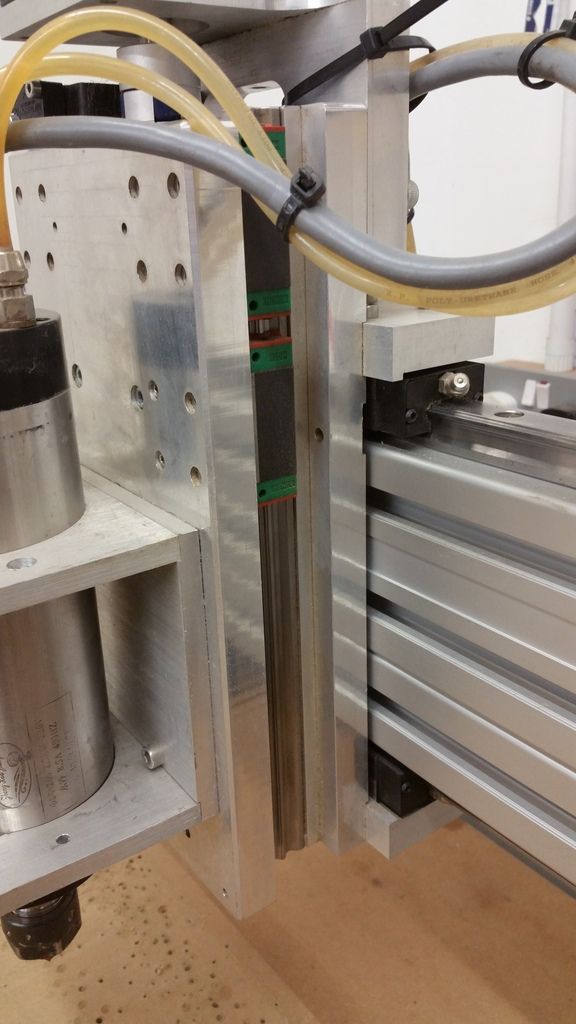

It has Hiwin 15mm on the Y axis with central 25mm ballscrew

Hiwin 20mm on the X with 25mm ballscrew

Hiwin 15mm on the Z with 16mm ballscrew

Motors are nema 34 size not sure about strength of them

There is homing or limit switches on the x and z but none on the Y.

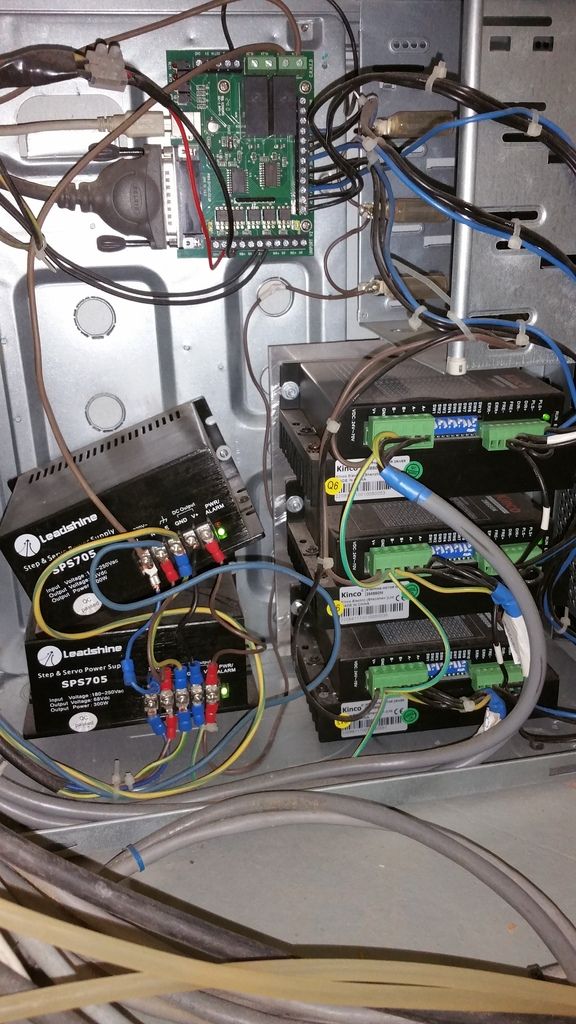

The electronics live in an old PC case

A Breakout board uniport from diycnc

2 leadshine SPS705 power supplies

3 Kimco stepper motor drivers

The frame is mostly 45mm by 90mm extrusion and the x and z plates are all 20mm.

The spindle is 2.2kw chinese watercooled, it is controlled by this thing.

However it only seems to be controlled by the small dial and switches at the bottom which adjusts the speed but reads in hertz so I will have to do some maths on that. The other buttons on the removable control bit don`t appear to do anything.

So now my new mission is to get this thing working perfectly so I can learn about everything and get productive, I would still like to build my own but this might be a better use of my limited time at this point.

I got the machine running with the PC that came with it mach3 was installed as well as Vectric aspire (which i never got a chance to use). I managed to get everything jogging nicely using mach3 so I know that the power supplies and stepper drivers are all working at least.

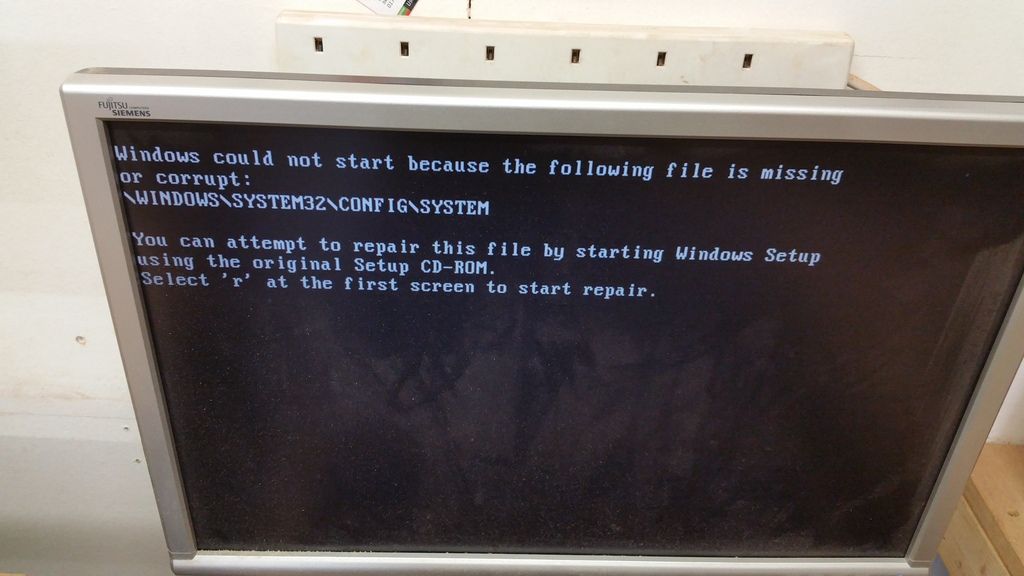

However before I managed to get much further, I was trying to establish a home position etc. The Machine stopped jogging and didn`t want to respond. The only evidence of an issue was a red light on one of the sps705 power supplies. So I rebooted everything and then I got this unhappy sight.

So I am a bit stuffed for now. However when I turn on the system all the LEDs in the control box are green again (not sure exactly what this means but I am looking at it positively).

I will try to recover the system with a usb boot recovery if I can ( it is running XP I think). If not its new pc time.

This leads to a question (first of many) .

Should I stick with an old system with parallel port and 32 bit or go for a more modern and thus hopefully reliable windows 8 or 10 system ?

I am thinking of a small media box type pc with maybe fanless design for less dust issues or even a laptop.

As I understand it this would require another board to communicate with the PC via ethernet or USB and the parallel port on the breakout board.

Any recommendations on best method for this?

Computer problems aside I started cleaning up all the ballscrews and tracks etc. I cleaned up the x axis ballscrew and track with some boeshield and it came up nicely.

What is the best grease to use for the ballnuts and carriages ?

The bigger 20mm carriages have grease nipples but the 15mm ones don`t have any. How do you grease these ones.

Also I have noticed that the bearing on the drive end of the X axis is a bit clicky and needs changing the same bearing on the Y is suspect too. Z is fine.

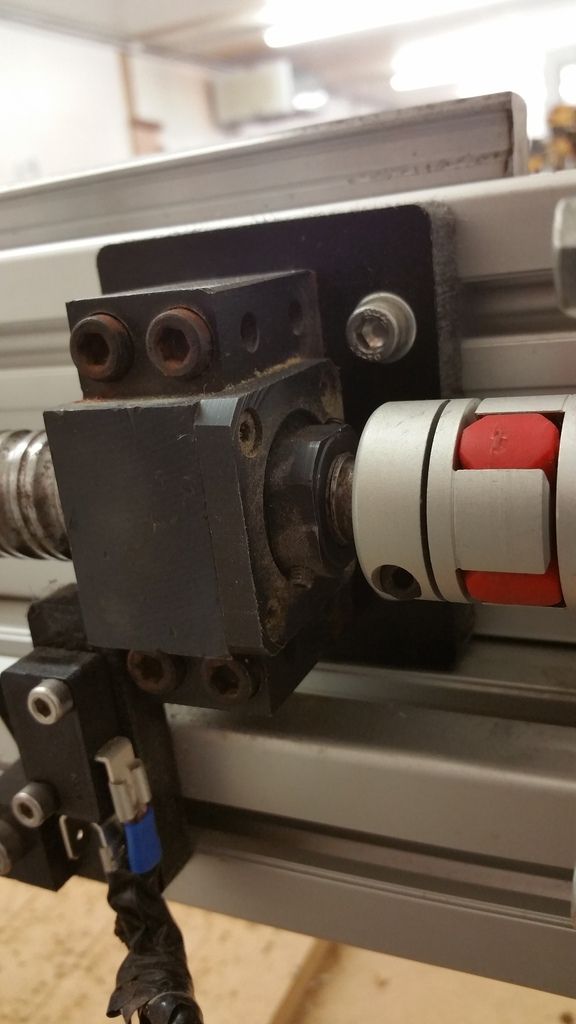

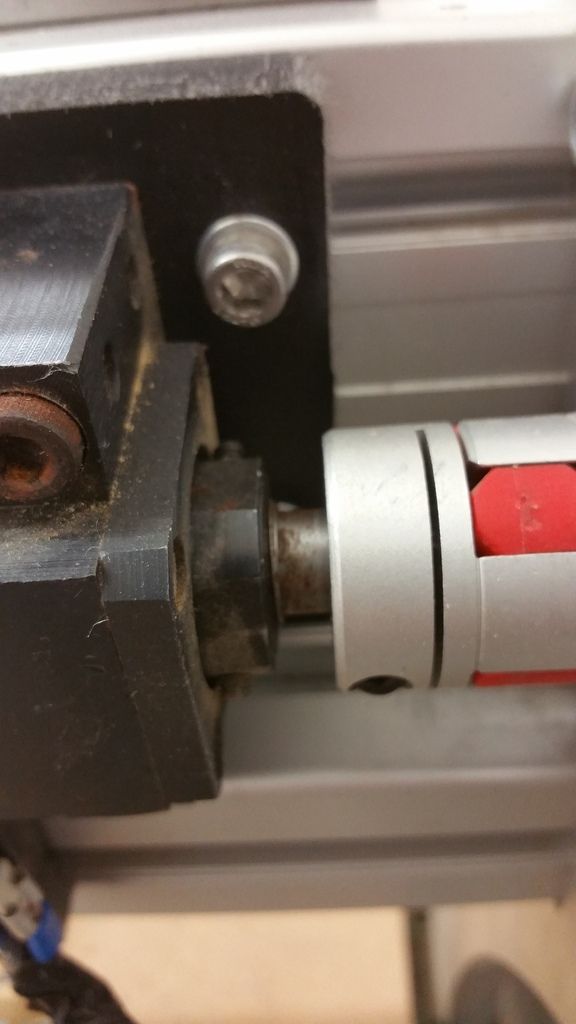

The blocks are these ones

The shaft has been turned down to 12mm just after the bearing before the coupler, the bearing block is 26mm wide and about 70mm high. does anyone know the name or type of this block bearing?

Can the bearing be replaced easily (ie without a press) or do I need to get the whole block?

What water/ coolant is best for the spindle, it has a small fishtank style pump. I am just using the same water (demineralized apparently) that was already in it. But I will be making a better tank arrangement before i use it again.

Oh and can you buy those green grommets for the rails separately? the holes were filled up with dust.

Thanks for reading all that.

Ollie

-

09-06-2018 #12

I think you have done well if you bought it right. Now re the pc. first I would re-seat the cables to the hard drive and re-seat the ram as well. Before you start loading a new operating system try putting the drive (as a second drive) in another pc to see if you can recover any data from it like the XML file from the Mach3 folder as that will contain all the settings ect.

Bearings blocks you can buy the bearings (they should be AC bearings 2 No.) they should come out quite easily notice which way are fixed in there (ie back to back or front to front) the bearings will have numbers on one side to identify them. They also might have a shim between them.

The bearing block is known as a BK type It looks like a BK15 and the other end of the screw a BF type if it is floating.Last edited by Clive S; 09-06-2018 at 08:49 AM.

..Clive

The more you know, The better you know, How little you know

-

09-06-2018 #13

-

09-06-2018 #14

https://www.hiwin.com/pdf/lubricating_instructions.pdf

Add a grease nipple.

-

09-06-2018 #15

Doddy, great link, thanks.

I think I should be able to add grease nipples to the end of the blocks as shown in the manual which looks the simplest method.

However I have not been able to find anyone who sells them separately yet. Found a company selling loads of different ones but couldn`t see the thread size of them in the hiwin document.

Clive S, thanks for the info on bearings, I think they are BK17 as 25mm screws. Glad to know you can change the bearings without getting new blocks which may save a few quid, I will take one off when I get time and have a look.

As for the computer I have had a wiggle with the connectors etc and blown all the dust out with an airline. Tried a CD with the recovery part of XP only ( no original disk) but it wouldn`t have any of it. I will see if my brother can help as he is very good at IT stuff.

I am thinking of getting a UC300ETH-5LPT ethernet motion controller which I hope could be installed with everything else in the control box remaining the same. ie between the PC and the BOB .

This means that it wont matter what computer I use in future.

I am planning to use fusion 360 for cad/cam (its free and powerful ) but it will only run on 64bit systems. Also moving forward more and more software is going to be like that.

It seems like the uc300 eth was made for UCCNC initially and has a plugin for mach3/4. As I will need to learn from scratch anyway (assuming the pc is dead) might it be better to just get UCCNC and learn that. I know mach 3 has huge user base and more history so might get easier support. Any thoughts?

Thanks

Ollie

-

10-06-2018 #16

Can you remember the operating system ? e.g. Windows XP Home, Windows XP Pro etc etc. Do you have a sticker on the computer with the operating system details and product key ?

If so I am sure I can get you a Windows setup CD-Rom. If you don't know what you are doing get the computer to a specialist.

If you have these then the system can be rebuilt, but it is essential that you have a clone copy of the hard drive before you start. There a a number of essential files you need to secure.

Cheers, Rob

-

12-06-2018 #17

Cropwell

Thanks for the reply. I think it is definitely an xp system, though I can`t say if it is pro or home etc. No licence sticker or anything is on the chasis.

I tried a basic download of the recovery partition but I didn`t want to go any further. I was thinking of trying a usb bootable linux version to try and recover the files but it has been ages since I did that sort of thing.

I will get my brother to see if he can rescue the system or at least the drive, he has access to some rescue software for this sort of thing.

Longer term though I think a more modern system might be in order.

Ollie

-

21-06-2018 #18

It looks like the hard drive is dead. We tried various ways to get it sorted but no luck.

So I guess I will start from scratch with a newer PC which will hopefully offer good future proofing and reliability.

I have purchased a UC300 ethernet motion controller and a 5 volt power supply from CNC Drive so I will attach this to the existing control box setup.

Not sure what PC to get at this point. Obviously I don`t want to spend loads of money.

The choice I need to make is do I just get a lower powered PC to run the machine or get one at least capable of editing in fusion 360.

My workshop is 20 minutes away from my house and I could see it being a problem if I couldn`t just make a quick adjustment to a file or something without driving back home.

Apparently the Ryzen 2400g apu`s will run fusion quite well. https://www.youtube.com/watch?v=UHWwcStt868 (I have a Ryzen5 1600 in my home PC, it is fast and cheap)

Does anyone have any thoughts about this?

What Computers are you running?

And finally, if you were starting from scratch at this point in time, with no experience of either. Would mach3 or UCCNC be the best choice ?

Thanks

Ollie

-

22-06-2018 #19

I would rebuild the system on a new hard drive (That is because I have all the OS and software disks and several spare hard drives and no money)

I run Mach3 on a very old machine - a 32bit Pentium 4 2.4GHz with 896MB of RAM with Windows XP home installed. Mach3 doesn't need wizzy wizzy power. It is connected up to my home network, but the Internet Gateway is disabled as there is no virus protection. I regard Microsoft in the same category as malicious software. Apart from a couple of hard disk failures (crappy old drives !) The machine is stable and all my data and essential files (xml and licences etc) are copied on to the NAS drive.

As my new main machine, I have a 64bit Windows 10 installed on an Intel i3 3.6GHz processor, it runs Fusion better than my old machine, which limped through it like a pig on stilts. I have only been seriously using Win10 for a couple of weeks and I now seriously loathe Microsoft. My old machine is a Win7 machine which I intend to use by remote desktopping, but I need to set up a control panel to switch it on and reset it, when the machine is tucked away. All my files are on it at the moment and I am in the process of moving them onto the NAS drive.

If you are wanting to use Fusion in your workshop, you will need t'Interweb there. Maybe I am stating the bleeding obvious

That's the way I am set up and it works for me (apart from the process of change which is in progress).

Cheers,

Rob

-

22-06-2018 #20

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

can someone please help with hole dimensions

By reefy86 in forum SolidworksReplies: 38Last Post: 20-02-2016, 12:44 PM -

Hole Radius

By benkat in forum Machine DiscussionReplies: 0Last Post: 03-03-2014, 05:29 PM -

SBR16UU Centre hole.

By cambesol in forum Rails, Guideways & BearingsReplies: 3Last Post: 25-11-2013, 05:39 PM -

HELP! Problem drilling 2.39 dia hole in Ali casting

By woolley2002 in forum Machine DiscussionReplies: 4Last Post: 04-09-2013, 09:06 AM -

6mm shaft to 6.35mm hole?

By JuKu in forum Metalwork DiscussionReplies: 3Last Post: 15-12-2012, 02:29 PM

Reply With Quote

Reply With Quote

Bookmarks