Threaded View

-

22-09-2018 #15

Thanks for your comments.

I did that because the further I move them apart, the less z height I have, because I have only 300mm rails for the Z axis.

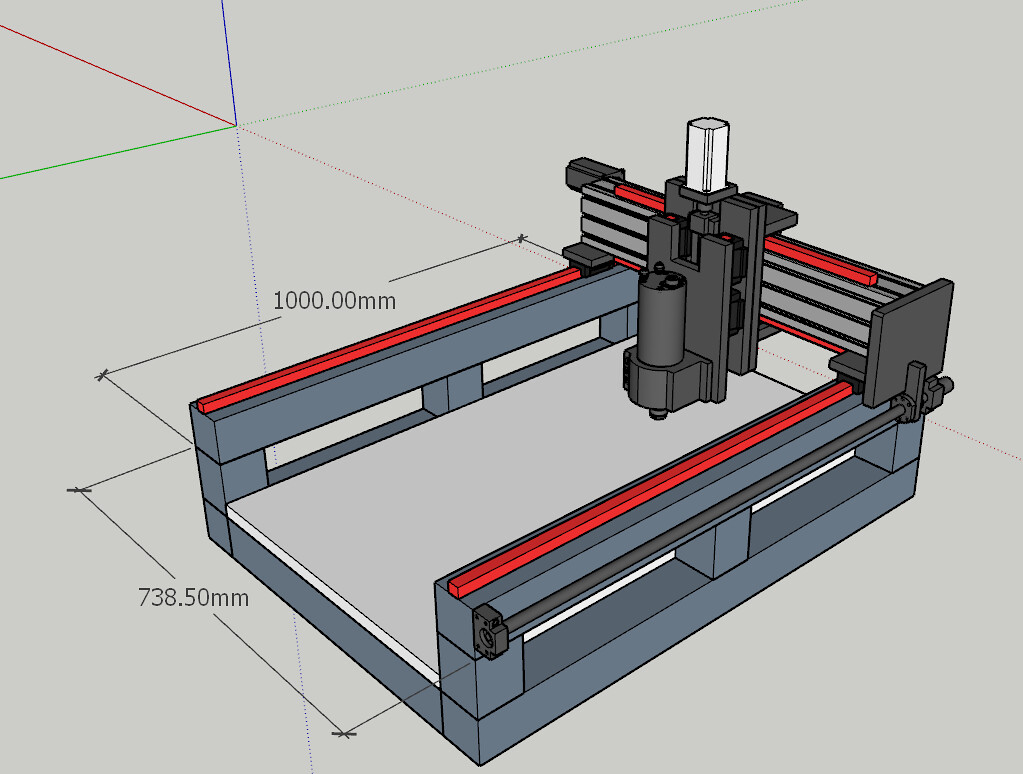

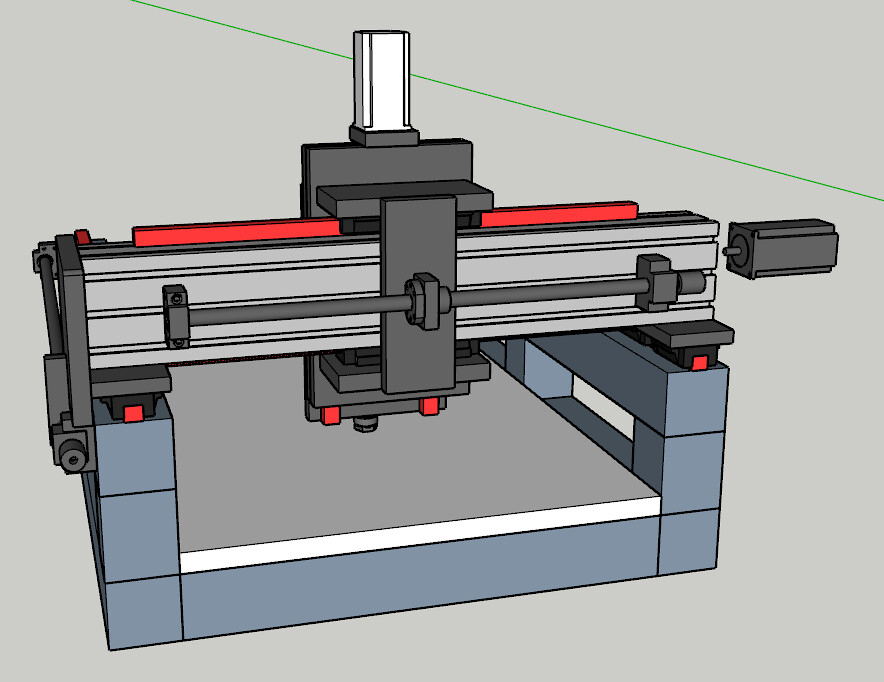

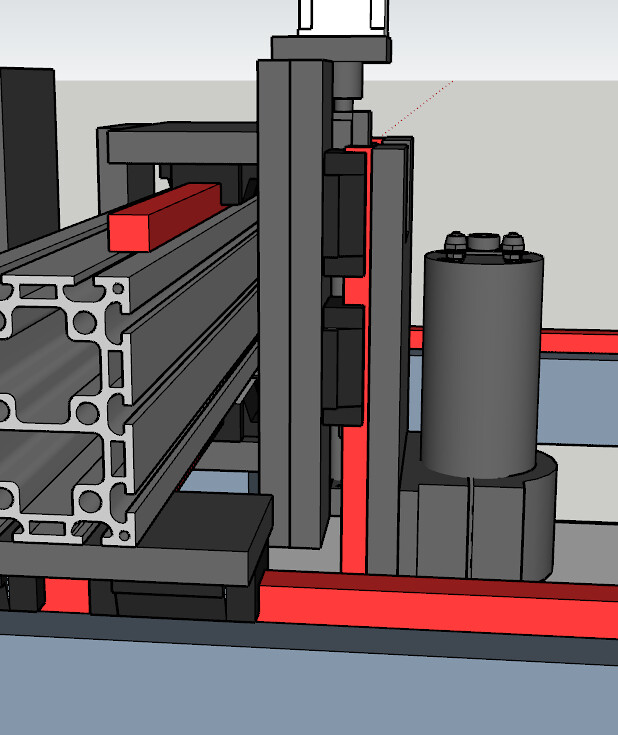

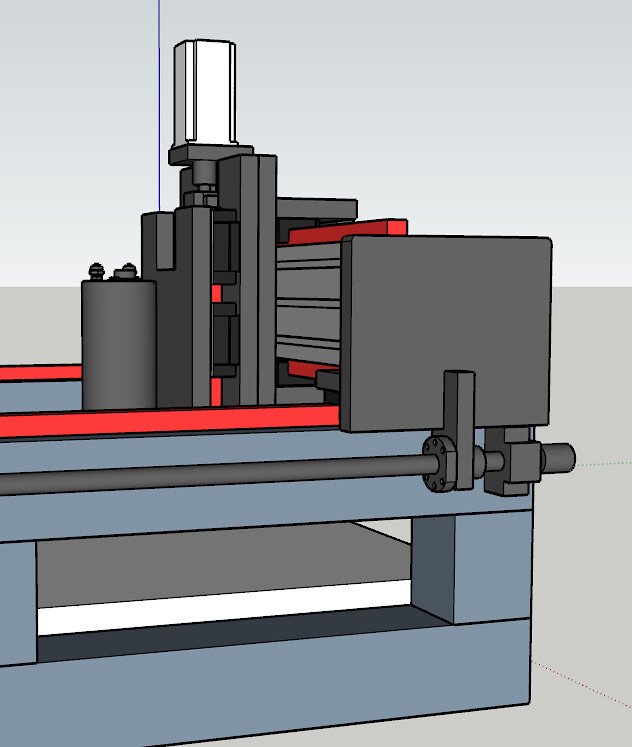

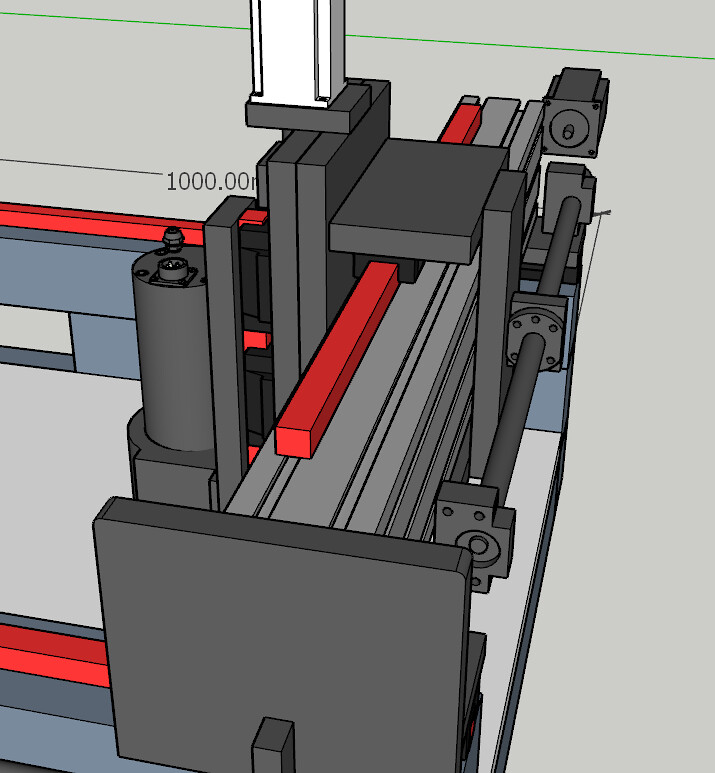

Here is the machine at the moment. The z axis is at the lowest point of its travel. I've modelled the ballscrews and rails etc exactly as they are. They arrived a few days ago. Still waiting for the second ballscrew for the x axis.

My only problem was trying to keep the z axis as close to the Y as possible, so that there is less overhang or twist forward on the gantry. So I had to move the ballscrew to the back of the gantry. Not ideal, but with everything being 16mm and 20mm alu plate, I figured it wouldn't pose too much of a problem. Thoughts?

I have now sourced 80x80x5mm steel box section, and I got it through a friend at work for £76 for a 7.5m length. Not too bad!

I've also ordered a 2.2kw water cooled spindle, 425oz motors and drivers. I'll be buying the transformers and caps soon for the power supply. Any idea what control board I should use?

Note I haven't modelled the second ballscrew for the x axis. Its basically a copy of the right hand side one.

Please let me know your thoughts?

Cheers

Neal

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Aluminium Extrusion Router Build

By NFryer in forum Gantry/Router Machines & BuildingReplies: 76Last Post: 03-07-2019, 07:59 PM -

Homemade CNC with Scrap + Chinese parts || Objective: Milling Aluminium ||

By laranjas3 in forum Gantry/Router Machines & BuildingReplies: 7Last Post: 16-11-2017, 10:18 PM -

FOR SALE: Aluminium Extrusion

By vigen20 in forum Items For SaleReplies: 2Last Post: 24-07-2012, 11:01 PM -

BUILD LOG: Aluminium Extrusion CNC Router Build

By joshendy in forum DIY Router Build LogsReplies: 9Last Post: 10-04-2012, 08:26 PM -

BUILD LOG: Work scrap bin router build

By Vic66 in forum DIY Router Build LogsReplies: 32Last Post: 17-01-2010, 08:51 PM

Reply With Quote

Reply With Quote

Bookmarks