Threaded View

-

28-08-2019 #8

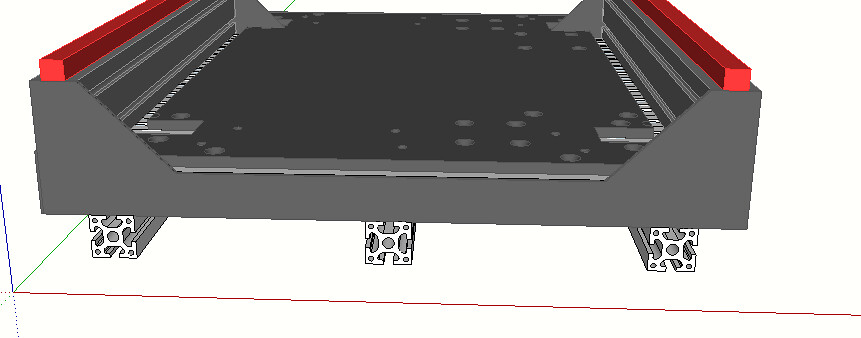

Thanks very much. Yes i have loads of 2mm steel plate lying around. I'd rather use that than buy new stuff. Is this what you meant by use the 10mm plate AND the profiles? I have the 10mm plate bolted to the platform created by the profiles. Front view.

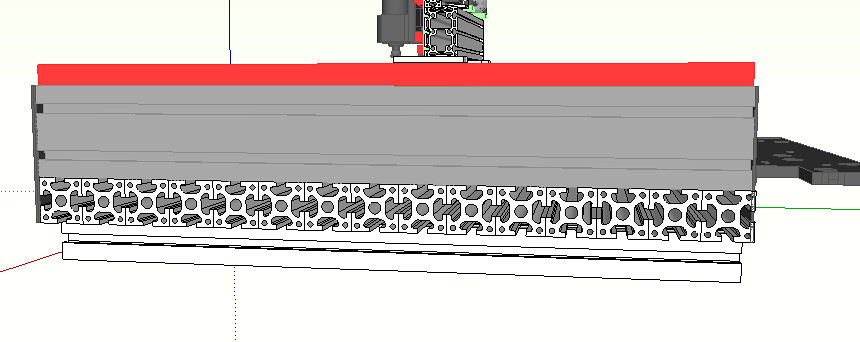

Now side view. IF I have enough profile i can lay them next to each other touching. But if not I will have to space them as in the second pic.

Thanks Jazz. Yes this is actually my current machine that I want to extend a little bit, but at the same time add a bit of rigidity. Don't get me wrong, it works great and I can get some decent cuts in aluminium, but I'd like to stiffen it up where i can, using what I have laying around. I removed the linear motion components to clear the clutter in the drawing so you could see which base and profiles i was referrring to.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

MicroRouter Spindle upgrade - advice and help required

By ngwagwa in forum Spindles & Drive MotorsReplies: 16Last Post: 26-05-2019, 02:52 PM -

Rigidity of aluminium profiles and rectangular tube sections....

By Voicecoil in forum Gantry/Router Machines & BuildingReplies: 6Last Post: 14-10-2018, 01:51 PM -

profile rail and purchase advice

By johngoodrich in forum Marketplace DiscussionReplies: 2Last Post: 17-09-2016, 07:53 PM -

Low profile, compact work-holding solutions. Advice sought.

By Wal in forum Tool & Tooling TechnologyReplies: 23Last Post: 26-08-2016, 10:45 PM -

advice on upgrade to 5 axis control

By alanb in forum General ElectronicsReplies: 17Last Post: 27-07-2012, 06:29 AM

Reply With Quote

Reply With Quote

Bookmarks