-

30-08-2010 #1

Hi All,

On Ebay:

http://cgi.ebay.co.uk/ws/eBayISAPI.d...m=150838094505

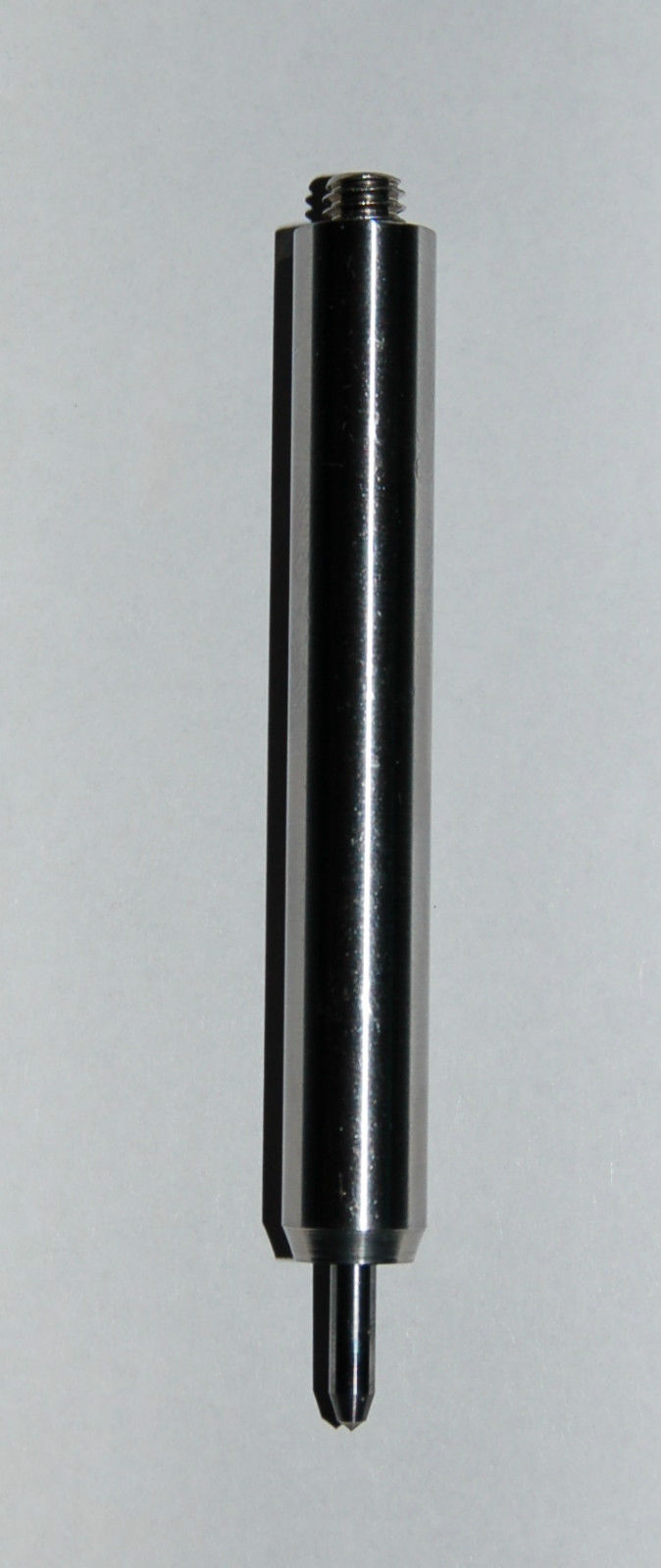

Drag engraving tool for half inch routers. I made half a dozen of these but it seems no ones interested.

Cheers,

Wilson.

Last edited by evildrome; 16-06-2012 at 02:18 PM.

-

30-08-2010 #2

To be honest I wouldn't pay more than £10 for an engraving tool bit.

To your plight of no sales...try putting it in the appropriate section related to CNC on ebay.....

http://shop.ebay.co.uk/?_from=R40&_trksid=m570&_nkw=cnc

-

31-08-2010 #3

Hi George,

A proper CNC engraving tool is not just a pointy bit of metal. The depth of cut is very small. This makes deviation in the height of either the job or your table a real issue. To compensate you require to spring the engraving point so that it can move up & down. This in turn requires that the fit of the engraving tool in its holder is nuts on as any sideways movement will show up on the job.

The amount of compression has to be adjustable and that means a method of adjustment plus you need to start with roughly the right strength of spring which means having a large selection or making your own (which is what I did).

Now we come to tip geometry. The tip should be machine ground to 120 degrees. Not the tighter angles you see on scribes and pointers etc.

So, you could make your own for less than a tenner but you couldn't buy one that'd really do the job for a tenner.

Regarding Ebay categories, that link you supplied is a link to Ebay with a search term. Not a category.

The item is listed in

My item does show up in your link but on page 27 or something because the default listing is by date and its a Buy It Now with 5 days to go.

Cheers,

Wilson.

-

31-08-2010 #4

Wilson,

You have to excuse George, he's been on this board for two months, has a higher post count than only the long serving regulars, knows everything, still asks stupid questions and has never posted anything of use so far.

Reminds me of that sign on my brothers workshop wall.

"Employ a teenager whilst they still know everything !"

.John S -

-

The Following User Says Thank You to John S For This Useful Post:

-

31-08-2010 #5

Who got out of the wrong side of bed this morning then?, you do realise that comment can put new members off asking questions whether they're stupid or not.

Wilson.it should be in the CNC catagory on ebay as its CNC related item

-

31-08-2010 #6

Hi Wilson

Will it cut steel or is it only sprung for Al?

Will it cut deeper if I go around again?

best

Robin

PS: Sorry to see you caught up in board netiquette so soon, John takes no prisoners. OTOH he knows his CNC so we let him get away with it :naughty:

-

31-08-2010 #7

I donít think I need to address Georgeís post and thank you for your reply; it covers everything that needs to be said as dose Johnís.

I too have the same questions as Robin, I donít know a great deal on this topic but I would like to do some engraving at some point.

So yea, great little product, if the spring is setup for working with Ali, would it be an option to supply other springs, as like a set for working with different materials. Iím guessing you would have a great experience in what works and what doesnít, could also be an ďAdditionalĒ nock on sale for you as well, dose the current version lend itself well to swapping the springs or would you need to rework the design/construction?

Iíve watched the video on your eBay listing, the results look good. Below is a pic of a tool another member was working on, Iím not sure how far they got as they are very busy with other things at the moment, Iím just showing you for interest really nothing else.

Cheers,

Lee

Lee

-

01-09-2010 #8

Hi All,

I shall respond in order:

John: thanks for excusing George. I'm not easily offended and can take criticism. Even if its a bit left field.

George: I am intrigued by the 'CNC' category in Ebay. All the CNC stuff I found, including my own appears to be in

Business, Office & Industrial >

Metalworking/ Milling/ Welding >

Other Metalworking Tools

e.g. http://cgi.ebay.co.uk/CNC-PLASMA-GAN...ng_Supplies_ET

Is there a category Business, Office & Industrial > Metalworking/ Milling/ Welding > Other Metalworking Tools> CNC ?

or maybe Business, Office & Industrial > Metalworking/ Milling/ Welding > CNC ?

I couldn't find it. I'd be grateful for a link.

Robin: The tool will cut glass, so yes, it'll cut steel, stainless, DO1 tool steel, you name it. If you want a deeper 2nd pass, add a bit of Z. Maybe 10 thou but you should, with a bit of experimenting, be able to get the depth you want in one pass.

The spring rate is just one parameter. There is a pre-load grub screw in the end, plus you've got the Z to think of. The spring is *very* stiff. You need almost no pre-load at all for acrylic & ali.

BTW, just so we're clear, this is a 'drag' engraving bit. It does not rotate. You basically push it in as far as you need and 'drag' it around the surface.

Lee: I think I've covered your points. One additional thing though... as the tip is sprung you can engrave curved objects like pens, buckles, golf balls, pool cues, etc, without having to program in their profiles. Which is nice.

BTW must be the MYCNCUK effect but I sold one today! And to an American no less.

Cheers,

Wilson.

-

29-06-2021 #9

I get the occasional enquiry about these.

I no longer sell them on Ebay but I now have a website.

http://www.dragengraving.com/

Cheers,

Wilson.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

CONVERSION: Half baked CNC mill

By John11668 in forum Conversion Build LogsReplies: 3Last Post: 26-05-2020, 10:42 PM -

Is there a specific setting for using a diamond drag tool for engraving?

By petesos in forum Tool & Tooling TechnologyReplies: 4Last Post: 14-03-2014, 12:22 AM -

diyCAM: Carve Released Ė Half off ($25) for first 50 customers!

By Chemeleon in forum Manufacturer NewsReplies: 0Last Post: 19-08-2013, 12:46 AM -

M542 driver (Zapp) half or full current?

By Smiler in forum Stepper & Servo MotorsReplies: 9Last Post: 09-07-2013, 09:02 PM -

WANTED: Boxford Imperial Lead screw + Half nut

By rnr107 in forum Items WantedReplies: 0Last Post: 26-12-2010, 10:01 AM

Reply With Quote

Reply With Quote

Bookmarks