Thread: Rotating Ballnut - design ideas

-

29-11-2019 #181

Do they know you are rotating the nut and tensioning the screw.? Makes big difference.

This is the first 10x5 machine using rotating ball-nut I've built, I've built plenty of 8x4 and the difference between them really surprised me.

The secret is keeping the nut rotation speed down and getting a good tension on the screw with nice straight pull.

Good luck

-

30-11-2019 #182

Aha! The point I had missed is that your 'smaller motor' required to drive a 32mm pitch screw with 2:1 pulleys is NOT smaller than the motor required to directly drive the 16mm pitch screw. In fact it may well be the same motor, which is at the heart of what I was trying to say. Thanks for clearing that up.

Is there a case for using the direct driven screw with a bigger motor? You are saving the cost and complexity of the 2:1 drive and halving the speed required from the motor, so running it in it's higher torque region anyway?

KitAn optimist says the glass is half full, a pessimist says the glass is half empty, an engineer says you're using the wrong sized glass.

-

30-11-2019 #183

-

30-11-2019 #184

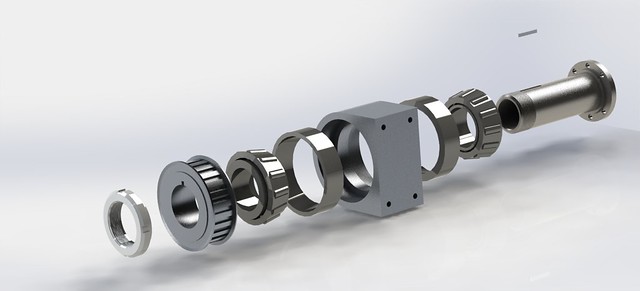

Don't need end bearings because not spinning the screw. The ends need to be either externally threaded or internally-threaded so you can tension the screws. I've used both methods on different machines and prefer externally threaded as can get more torque.

The force required to take Sag out over 10ft is considerable so make sure the brackets holding the ends are substantial and adjustable so can align screw in two planes.

-

The Following User Says Thank You to JAZZCNC For This Useful Post:

-

30-11-2019 #185

Can do either but using a larger motor usually doesn't cost less because requires larger drive and often more volts so larger PSU.

However, on long machines rotating nut wins hands down and requires a belt connection, so the ratio is no extra cost. Rotating the screw on the long machine means much larger ballscrew is required and this really starts to ramp up the costs because everything scales up with it, Bearings, couplers, motors, drives, PSU

Even then a rotating the screw system cannot achieve the feeds a rotating nut can.

-

30-11-2019 #186

Reading this thread with interest (as I may need to go this route on my "big" machine soon), I noticed the concerns over rotation speed of ballnuts. This made me recall some stuff I read in the TBI catalogue some months back about different types of ballnut (differing mostly in the configuration of the return paths) and their relative speed capabilities, worth a read and maybe doing the sums they outline there.

-

01-12-2019 #187

-

01-12-2019 #188

What's the thinking behind the shortest possible nut please?

The concentricity is an obvious thing and might rule out some of the cheaper offerings if my experience on the machine I've just completed is anything to go by. Having set everything up and got it working smoothly I thought I'd spin one ballnut through 180deg to get better access to the lube nipple. Major fail, that side of the axis got really stiff, it turned out that the casing/flange of the ballnut was something like 1 or 2 degrees out of alignment with the axis of the screw.

-

01-12-2019 #189

access/interference and balance/inertia mostly, it's no big deal and depends on the design to some degree but shorter is better in my experience.

It's not always the case obvious to everyone that's why I mentioned it. However most ball-nuts, even the cheap ones, have a machined reference surface on the outer body which you can chuck upon and skim flange if needed. Thou I've not had any issues if honest.

-

25-04-2020 #190

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Rotating Ball nut

By drumsticksplinter in forum Lead Screws, Nuts & SupportsReplies: 30Last Post: 12-05-2020, 08:01 PM -

Interesting Papers on heavy duty design, vibrations, composites and column design

By D.C. in forum Gantry/Router Machines & BuildingReplies: 15Last Post: 25-06-2016, 10:13 PM -

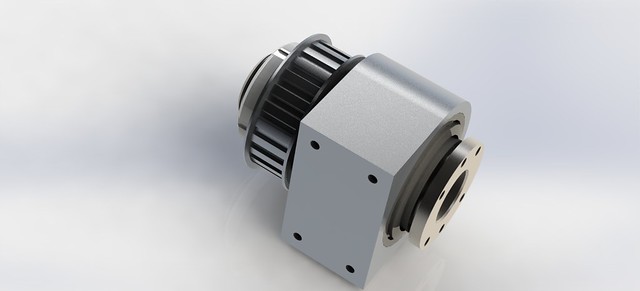

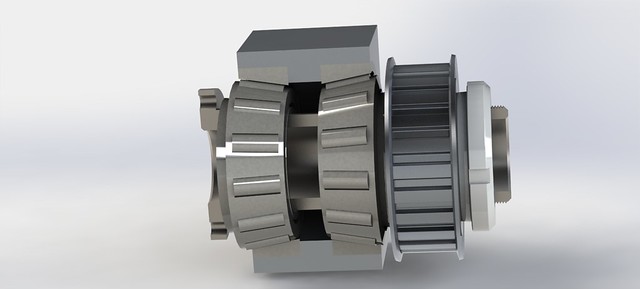

Rotating Ballnut Design MK3

By Jonathan in forum Linear & Rotary AssembliesReplies: 0Last Post: 15-12-2013, 01:35 PM -

advice on floating bearing - outer ting rotating

By dsc in forum Lead Screws, Nuts & SupportsReplies: 8Last Post: 18-11-2013, 02:23 PM -

Design help etc required with DIY CNC Router Design / Build

By MikeyC38 in forum Gantry/Router Machines & BuildingReplies: 12Last Post: 21-10-2011, 04:50 PM

Reply With Quote

Reply With Quote

Bookmarks