Thread: Siff' Build Log

-

26-07-2011 #11

Using aluminium because I can get it cheaper than steel and my rails are sitting on ally extrusion. That would mean I could then weld the ally extrusion to the base.

I'll add something in to make the bearing adjustable.. something I never thought about, so thanks!

I've reinforced the joint between the x and y axis, but I believe the bearing plates will be strong enough. I know some builds don't even use bearings on the 'floating' side and they will be made from 15mm ally.

Wish I could lower gantry but i'm trying to avoid using timing belts/pulleys where I can, so I had to raise it so the motor would clear the ballscrew :sad:

Also, quick question, where do i get pulleys from with a 10mm bore to fit the ballscrews? And can I get the belts in any length? Should I add a tensioner further down the line?

Finally, once I have bolted together all of the y axis and confirmed it is square/smooth etc, If I weld along the seems (lack of a better word) will it cause the ally to distort at all?

Cheers, Joe :naughty::naughty::naughty: (looking forward to getting it built)Last edited by everyreasonto; 26-07-2011 at 09:46 PM.

-

26-07-2011 #12

That sounds reasonable as long as they are mounted securely.

I think this is the cheapest place (HTD is the best):

http://bearingstation.co.uk/products...HTD_Pulley_5mm

You could drill it out to 10mm, but that's very hit and miss unless you have a set of drills in 0.1mm increments and even then I'd bore it. Or use a reamer, but then it's still not likely to be concentric.

Get them delivered to me and it's only about a 10 minute job for me to bore them to 10mm accurately.

There's various length belts at that site ... you'll soon find the formula to work out the belt length for a given centre distance (it's pretty simple). If not I can send you a spreadsheet with it. I just made it so that the 4 holes that mount the motor are slotted so that you can accommodate different length belts and different pulleys.

It defiantly would with steel, ... this implies it's worse with aluminium:

http://www.aws.org/wj/2003/02/028/

You need to design it such that there is adjustment designed in to the relevant parts such that it does not matter if it distorts. Obviously clamp it well when you weld it... I did that with mine and didn't really notice any distortion.

-

28-07-2011 #13

Ill probably do that then when I order if thats ok. Can you send me the spreadsheet please? I really can't be bothered to work it out, Just got back from work and i'm knackered!

Anyway, I've been buying today. I haven't ordered anything structural yet because i'm still working on it but I have bought:

Power supply, 3 x 3.1NM steppers, 3 x 4.2A drivers, 3 x couplings = £264

Breakout board = £13.99

4 x ballscrews, 6 lengths of rail, 12 x bearings, er11 collet set = £350 (exc import)

1.5kw spindle and inverter = £201 (exc import)

Still need to order belts, pulleys, extrusion, ally and some milling bits. Can't wait!

Oh, I also picked up a dedicated PC today for the workshop... 2.6ghz P4, 512mb ram, 40gb HDD, old ati graphics card and 15" monitor for £30!! Not bad eh?

Jonathon, what are the dimensions of the spindle mount that you made?

Regards

-

28-07-2011 #14

Found this, http://www.sdp-si.com/cd/default.htm ... simples.

This:

Or:

(but with more rounded corners...)

Or whatever you need really...the 150mm wide ones are 1/2" thick and the 125mm wide are 5/8" thick.

-

29-07-2011 #15

Looking so much better.

I agree with Jonathan, the X axis screw mounts look a tad flimsy. You need it rigid at the end which bears the thrust bearings.

Presume you are bolting it down in all 4 corners to something solid.

If you rearranged it a bit you could cover the X axis screws with aluminium angle and shield them from the worst of the swarf coming off the tool.

Anything you weld will distort. Okay to weld so long as you can machine it back to square after it has cooled down.

Very refreshing to see someone actually taking advice rather than rushing in to it and having to make a Mk 2 very soon after the Mk 1. Keep drawing, you won't regret it

-

04-08-2011 #16

Update time!

Rails etc haven't arrived yet so I've been busy getting my garage ready. It was empty before, so I've built a workbench and put it on it's own RCBO protected ring. I also got my workshop PC set up:

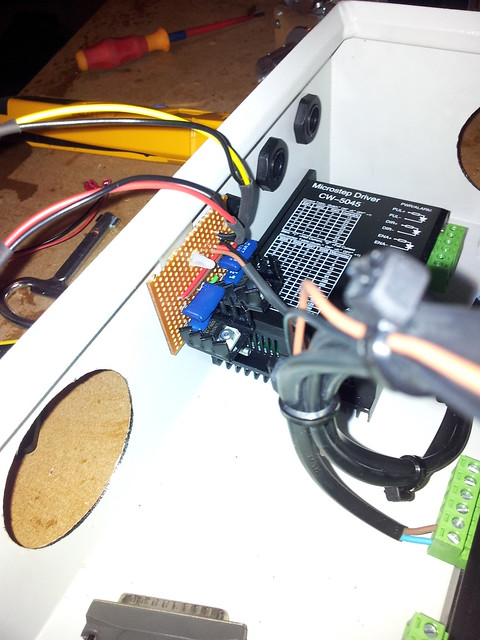

My steppers/drivers have arrived so I began creating my box of electrickery! :dance: These are all terrible photos by the way (taken on camera phone with a sprinkling of couldn't be arsed) I don't have any progress photos just the almost finished box:

My homemade 24v/5v power supply for the cooling fans and breakout board:

This shot shows the almost finished box except for the cooling fans because they haven't arrived yet. The stepper drivers have been bolted to the case and are covered in thermal paste where they make contact. You can also see my line laser on this shot, which is going to be for my 3D scanner project. Fans + Filters will be attached on the outside.

I'm still waiting on the breakout board and E-stop switch, which will be fitted in/on this case.

I've used glands and filters on all openings to keep dust out. The only possible place for dust to get in is the brush plate at the bottom, it will keep 99.9% of the dust out though so i'm happy.

I've also got a homebrew temperature sensor gizmo, that will let me know if the case is getting too hot. I doubt this will happen because, erm, well, it just won't! :)

Also, I've only got a baby pillar drill so I couldn't get the case under to drill those 60mm holes... they were a pain in the Harris to cut by hand and my baby walty almost burned out!

Thankya, goodnight, much lav!

-

08-08-2011 #17

Hi guys, just wondering if I could get some help. I can't seem to get my steppers to turn via mach 3. I know the motors are wired up correctly becuase I tested by shorting enable and the simulating pulses with a link wire and they turned just fine.

I've set up the correct port and pins in mach 3 (or so I think!), but it is as if it can't see the breakout board? The emergency stop button doesn't do anything and I don't know where to start looking... I don't know if I was doing it right, but I resetted the software on mach3, went to diagnostics and it showerd all 3 enables were on. I tested between the gnd pin a pin 1 on the parallel port and got nothing? I am howerver getting around 4v on on pins 12, 11 and 10.

Cheeers

-

08-08-2011 #18

What breakout board do you have? Does it have a charge pump and if so is it configured? You don't need to do anything with the enable inputs.

-

09-08-2011 #19

Hi, it's this breakout board:

http://www.zappautomation.co.uk/zp5aint-p-499.html

It's being run from a regulated 5v supply, I don't know if it has a charge pump

Didn't have time to recheck all of my wiring but i'm going to have a fiddle tonight.

Some good news though, my spindle arrived today! Seems excellent quality and I can't wait to get it fired up after i've configured it. Does anyone put anti freeze in their water to aid in cooling/ add corrosion resistance?

Cheers, Joe

-

09-08-2011 #20

Doesn't look like it has a charge pump...

http://www.slidesandballscrews.com/p...d%20manual.pdf

You should put something in the water to stop corrosion / algae etc. I've not yet but will do soon.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

BUILD LOG: New Build - For Your Amusement - MK-2 build

By Karl in forum DIY Router Build LogsReplies: 12Last Post: 08-02-2017, 08:03 PM

Reply With Quote

Reply With Quote

Bookmarks