Thread: Aluminium CNC log.

-

19-09-2011 #71

m_c ... looks like we're of the same mind - our last posts are virtually identical!

My mill has about 0.45mm backlash on X and 0.3mm on Y and it's no problem when using the machine manually. You just make sure to if it's a bigish cut lock the slide that your not moving, and when you move that slide to the required position compensate for the backlash by approaching the point in the same direction. You will also generally want to use conventional, not climb, milling.

Look for some thumbscrews that apply pressure to the gib strips to lock it. Don't move the other screws on the gib strips ...

-

19-09-2011 #72

Also ramp milling is essential when dealing with large amounts of backlash.

-

23-09-2011 #73

-

24-09-2011 #74

-

07-12-2011 #75

Holy Batman what's this? an epic thread Resurrection?

Yes, I abandoned all hope of making a CNC machine myself. My equipment just isn't accurate enough for my perfectionism.

So, I've dropped in the big guns.

The frame of my CNC is being Water cut, I have just paid for it, so it should be coming X-mas time.

I think if it comes X-mas eve I may wrap it up and give it to myself as:

1. I'm not getting many presents this year

2. See above,

So hopefully there will be an update here soon! and a proper one, Not like this.

Merry Xmas all.

-

07-12-2011 #76

good because I was going to send you a email

asking to buy it off you cheap:rofl:

asking to buy it off you cheap:rofl:

Have a good Christmas

James

-

05-01-2012 #77

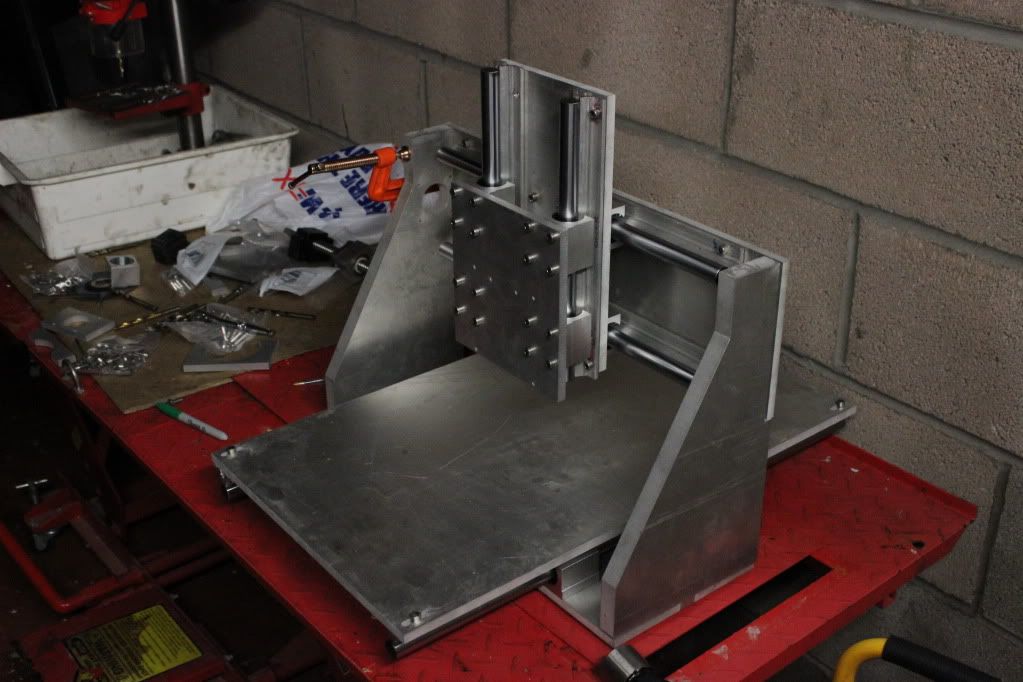

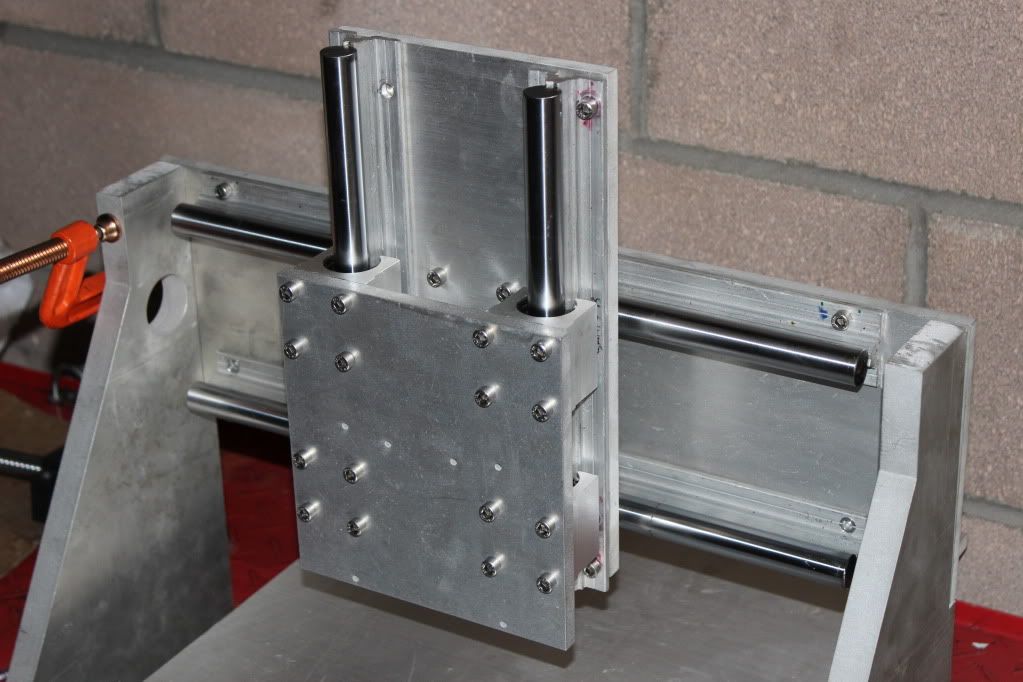

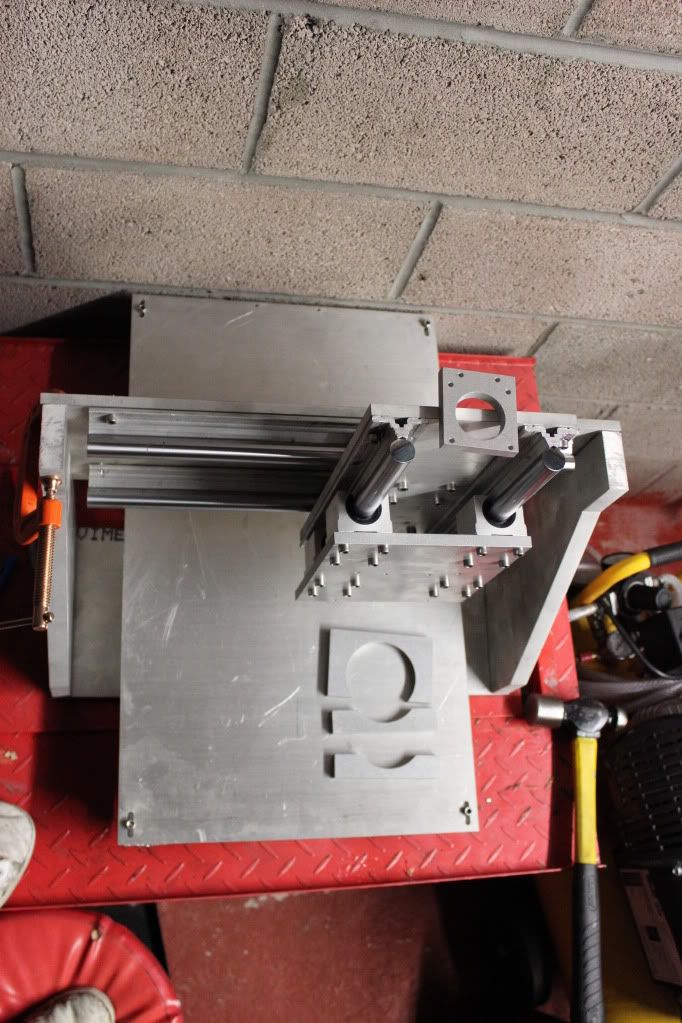

Ok, Finally got my stuff from the water Cutters and it's PERFECT!!

The frame is just resting together ATM, need to get two M6 nuts and mount the rails properly. The ball Screws should be in there tomorrow and the electronic sorted out over the weekend.

From a pile of metal to the photos above took about 30 minutes! so nice and quick :D

The company that did the water cutting was called Yorkshire Profiles.

-

06-01-2012 #78

Yes jess

that looks really nice mate I wish you good progress for the weekend I'm looking forward to seeing it finished

James

-

06-01-2012 #79

Well done. Good to see it coming together and best of luck with the rest of it.

Michael.

-

10-01-2012 #80

Ok, So i've mounted most of the bits, all I'm missing now are the stepper holders and the spindle mounts.

Also, What kind of wiring do I need? This will be used for my Steppers, Spindle to VFD, and generally all the wiring.

Thanks, Pics soon.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Aluminium box section

By martin54 in forum Gantry/Router Machines & BuildingReplies: 11Last Post: 28-10-2012, 01:13 AM -

First Aluminium cut

By luke11cnc in forum Computer SoftwareReplies: 15Last Post: 24-02-2012, 09:39 AM -

RFQ: Aluminium sculpture to be CNC'ed

By dav in forum Projects, Jobs & RequestsReplies: 6Last Post: 07-01-2012, 04:37 PM -

Aluminium passivation - for aluminium to be used outside

By CHudson in forum Metal Finishing TechniquesReplies: 4Last Post: 06-04-2011, 09:18 PM -

MDF or Aluminium

By rob_colby in forum Gantry/Router Machines & BuildingReplies: 3Last Post: 24-10-2010, 09:36 PM

Reply With Quote

Reply With Quote

Bookmarks