Thread: My 1st homebrew CNC.

-

03-11-2008 #1

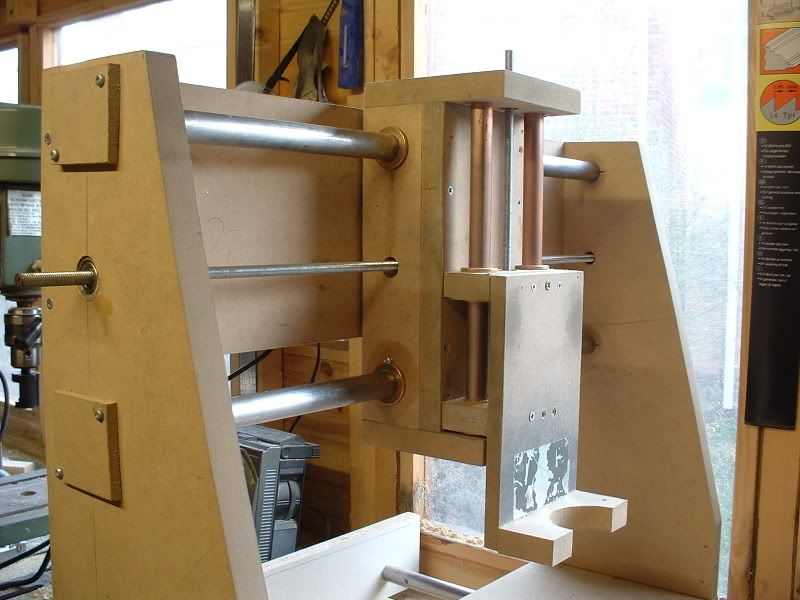

Hi guys, after many months in fact it seems more like years I have finally started my 1st CNC build consisting of 20mm MDF,Oilite bushings and ground linear rails.

Well have to admit given the chance to start again and recommending what I have learnt and messsed up I certaily would not use the oilite bushings ever again, they are most unforgiving and if you think that you can drill 2 holes a said distance apart like I did and get it right 1st time "WRONG!" literally every piece of the build I had to make 2-3 times very frustrating and very annoying, to be honest if I had taken the angle and skatebearing approach this machine would have been finished as regading all the linear motions working ie X Y and Z.

I started with 2 X 1 metre long 20mm OD ground steel rods for the X axis ie forward and backward motion, 2 X 600mm long 20mm OD ground steel rods for the Y axis left to right motion and 2 x 16mm OD for the Z axis, I thought I would have a generous size machine capable of cutting a good size of work when it comes to showtime.

I started the machine on Monday and have built the main gantry as well as the Z axis and again without alot of frustration with the bushings have now got the machine moving by hand very smoothly and there is virtually very,very little play and should eventually once its showtime cut and produce some accurate results, although I will only cut wood parts it should be more than adequate but again we will see as mister "sods law" hasn't reared his ugly head again. The Z axis should have a range of between 3"-4" inches of travel more than I need.

I will use for the X axis motion the skatebearing/angle approach as I cannot for the life of me go through with the problems that I had with the rest of the build and I am almost 100% positive this will produce a beautiful smooth motion for quite a reasonably heavy gantry. I will try and get some pics up tomorrow so I can show you all how its turned out and have to say its quite a thrill to be making my own CNC as I have trawled this forum endlessly searching for tips,plans etc,etc although I have quite honestly not worked from any plans but built and measured as I have gone along and have enjoyed it very much.

I will be starting to think about leadscrews and the drive components so would like any help I can get in what would be reasonable components to use. I have thought about using 8mm threaded rod which I can get here in the UK from my local Screwfix or B&Q depot and using a skate bearing to hold the rod in place as its a perfect fit "BUT" for the life of me I cannot think how to fix it in place ? I know that when the stepper motors are fitted I will use an adapter from 1/4 inch or 6.35mm to 8mm but how do I fix it at the ends of the rods to keep it spinning freely and keep it in place without moving ? I have tried to look at other builds but cannot for the life of me see any pictures of what I need to do. I thought I would ask here as I do not want to drill any unecessary holes and risk making errors as I do not want to go about making what I have got moving perfectly again which I know will present me with problems, any help and advice will be greatly appreciated.

I guess the main thrill for me is learning what to do and not to do and have this machine build me my next one which will be an awesomme task and more accurate and I have loads more other questions but I'll save them for later.

-

04-11-2008 #2

Hi Kammo,

Read this post and had a sense of deja-vue! I hope my reply on CNCZone was helpful...

-

05-11-2008 #3

Many thanks Irving and yes it was very helpful indeed.

-

05-11-2008 #4

Bro I couldn't agree more and have to admit I am pretty good at manufacturing things but this CNC is very trying at times I nearly threw the damn thing across the workshop. Most of the build in all honesty has been enjoyable but like I say its my 1st so the next one should be easier as I can machine the parts more accurately.

Kip do you have your machine running yet ?? I am still toying with the idea about using the 8mm threaded rods but may still do as I am on a budget and would like to try the trapezoidal leadscrews that so many are using, where is the best place for them ? What size would you recommend ? my machine will eventually have a cutting area of about 28 inches X 17 inches X 3-4 inches. I know its alot of questions but I could do with some expert advice. If I was to stick with the 8mm threaded rod from B&Q what sort of backlash nuts should I use or maybe make, has anyone on here made there own for this type of threaded rod ?

-

21-02-2009 #5

Hi guys managed to fit my main carrier bearings on my machine on the X axis, now would like some opinions if this is a good way or bad ? I haven't yet seen a machine with the bearings fitted in this configuration but it was easy and I also have scope to support the 20mm round rails without the chance of any impedemnet from the bearings if I choose to do so. Hope you enjoy the pics and any comments please advise. Laz

-

22-02-2009 #6

What stops it lifting ?

JS

-

22-02-2009 #7

At the moment nothing is stopping the whole gantry from lifting up and it will only have a worktop/surface spanning the 2 uprights holding the X axis rails, so in actual fact the only thing that will hold it from lifting will be the threaded rod when its connected to the bottom of the gantry and obviously this will be connected to the stepper motor one ened and the other end will float within the bearing at the other end. At the moment it is bothering me but I might even fit a fixture which will hold a bearing so it rides under the table but also be pressing down on the gantry which will stop the lifting if it occurs.

John sure could use your expertise on this one bro ?

-

22-02-2009 #8

I think i would be bothered as well kammo !

Lee

-

22-02-2009 #9

I would just make two more trucks and extend the bolts you are using for bearing axles to attach the new truck at 90 degrees. With a bit of shimming the bearing which will now be underneath the tube can be made to contact it quite securely. So hard to describe this in words

Basically, keep the truck as you have it but bolt on another identical truck using the axle bolts from the first then shim. This will also allow you to support the rail with no interference. This will do what you want. You only need one extra truck per side so two new trucks to make Kammo, shouldn't take more than 15 mins so get cracking!

;)

Jeff.Last edited by Smiler; 22-02-2009 at 01:11 PM. Reason: I forgot a bit

Nothing is foolproof......to a sufficiently talented fool!

-

22-02-2009 #10

Id mount the bearings on the inside of the gantry on the left and right. Similar to joes cnc. That way you wouldnt have to redesign the x axis, although you may need to flip it over to give more clearance.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Homebrew Allegro uStep Driver

By epninety in forum Electronic Project BuildingReplies: 0Last Post: 06-09-2011, 11:11 PM

Reply With Quote

Reply With Quote

Bookmarks