Thread: 3 Axis CNC router

-

03-09-2015 #151

Has anyone come across this issue and know what is causing it. One of my carriages is very juddery and stiff - particularly in one direction...

-

03-09-2015 #152

I had that problem on one of mine when I dropped my balls....have you taken it off and looked to see if they're all there? Not sure why it affects one direction more than another....plenty of grease in it?

-

03-09-2015 #153

I should add that the seller I bought them off is sending a new one so not too worried - just wondered. Yes all greased up and no dropped balls!!

-

03-09-2015 #154

Not sure how many balls there should be in there to be honest.

-

16-09-2015 #155

-

The Following 5 Users Say Thank You to JoeHarris For This Useful Post:

-

18-09-2015 #156

-

18-09-2015 #157

Sorry for the high-jack but I've been wondering about best gantry geometry recently. I half remember a thread comparing some different alignments with simulation of force in various directions. Do I remember right? I kind of remember this 'L' shape being best, but I'd like to re-cap.

-

18-09-2015 #158

It depends who you listen to! This method got my vote. But some people like to sandwich the ball screw between two sections of extrusion to bring the screw closer to the stuff it's moving. I like the fact the this method protects the screw somewhat. Very strong from what I can tell!

-

18-09-2015 #159

Not sure about the Simulation thing but I can tell you from experience having built many many machines using this "L" design it works perfectly for Wood routers and is very stiff.!

If your wanting semi milling machine stiffness then you'll maybe want to go with something a little stiffer and heavier. But for wood routers and light Aluminium work then it's plenty strong enough.!

-

18-09-2015 #160

Thanks Jazz, I was not thinking so much about the specific build as the geometry. You could put those two sections in a kind of '=' alignment or the 'L' shape used here. The first is probably better to resist front to back force but the second will perhaps have a better mix of up/down and front/back strength. If I built mine again I'd use large and thick steel section with end plates to affix.

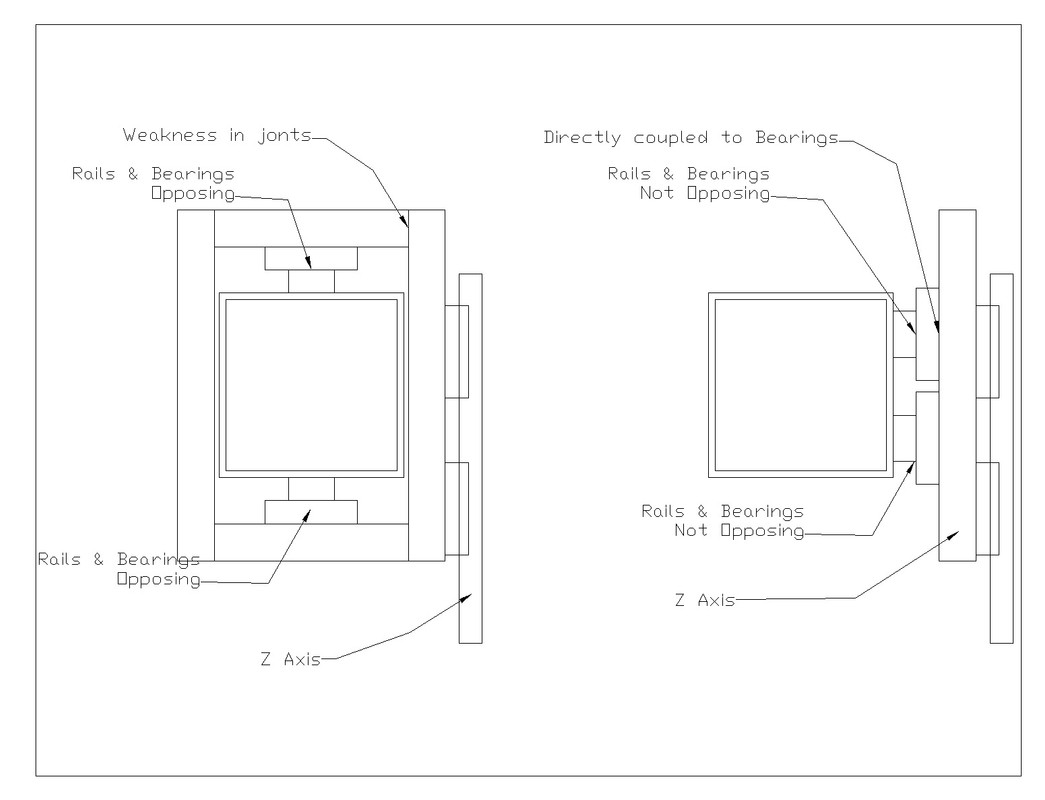

I've also been thinking about best placement of the X axis (sideways) rails. I mean say (for sake of simplicity) you had a square gantry section. You could put rails on the top and bottom so they are opposing but then you need to create the Z axis as a kind of box to wrap around the gantry. The joints in that 'box' will be a point of weakness. On the other hand you could place the rails on the front face of the gantry and the Z axis plate can attach directly. Which is better? If you have great rails and bearings with zero play I imagine the second option, but no rails are perfect.

This will help explain what I mean, I hope.

This would make building CNC machines easier! - https://www.youtube.com/watch?v=pevgkx69j8oLast edited by Tenson; 18-09-2015 at 11:59 PM.

Thread Information

Users Browsing this Thread

There are currently 20 users browsing this thread. (0 members and 20 guests)

Similar Threads

-

BUILD LOG: 3 Axis Router

By GTJim in forum DIY Router Build LogsReplies: 8Last Post: 22-06-2020, 08:49 AM -

3-Axis CNC Router - For Helices.

By Dalmango in forum Gantry/Router Machines & BuildingReplies: 4Last Post: 08-02-2014, 07:27 PM -

BUILD LOG: Wobbly: my first 3-axis router

By Sodster68 in forum DIY Router Build LogsReplies: 8Last Post: 20-01-2013, 10:28 AM -

3 axis cnc/router bed

By dudz in forum Marketplace DiscussionReplies: 23Last Post: 28-12-2012, 09:38 PM -

Need 6' x 4' bed, 4 axis router design.. Help..!

By fasteddy in forum Gantry/Router Machines & BuildingReplies: 29Last Post: 17-09-2010, 12:56 PM

Reply With Quote

Reply With Quote

Bookmarks