Thread: Outrunner Spindle Parts?

Hybrid View

-

05-08-2012 #1

Thanks for the info.

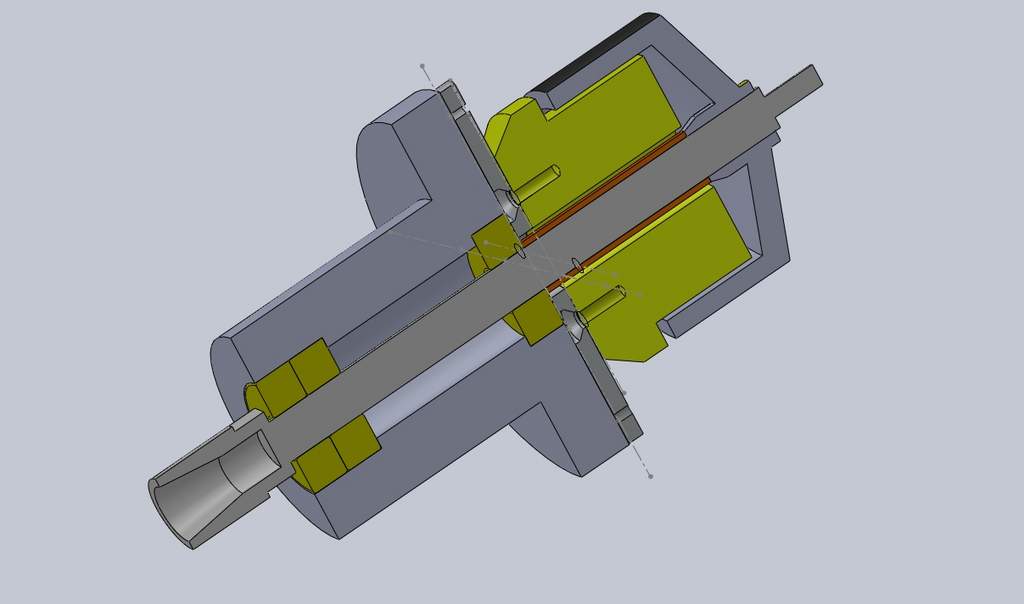

I wish to build something like the below picture, where the 8mm motor shaft is replaced with an 8mm shank er11 collet chuck. However I'm wondering about two questions.

1) How does the shaft fix to the motor? What is involved in replacing the shaft exactly, just whack the original out with a hammer and pop the new one in with another whack?

2) Why use such a long section of shaft extending from the bottom of the motor and then support it with additional bearings? Why not mount the chuck as far into the motor body as possible and dispense with the additional bearings? Like my hacked picture below.

-

05-08-2012 #2

1) grub screws in the bell housing grips the shaft

2) its to remove ALL the play that you would normaly get with any plain brearing (translates into poor finishes & poor cutting performance)

the nature of cutting promotes resonance in a big way, it would be interesting to see how well you would get on with the simplified design you propose so it may be worth giving it a go if your only cutting wood

if you want a good finish on plastics and ally im pretty (99%) sure you would be disapointed

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Chinese 300W DC spindle - is the spindle shaft grounded?

By HankMcSpank in forum Spindles & Drive MotorsReplies: 44Last Post: 26-11-2016, 07:25 PM -

2.2kw spindle parts

By Tomnewry in forum General ElectronicsReplies: 3Last Post: 14-12-2013, 09:30 PM -

CNC Spindle Repair and Spindle Replacement for any Machine of any Manufacturer

By spindeldoctor in forum Manufacturer NewsReplies: 0Last Post: 13-11-2013, 07:50 PM -

FOR SALE: ER20 DIY Spindle Parts

By Mad Professor in forum Items For SaleReplies: 1Last Post: 03-11-2012, 06:51 PM -

DIY Spindle - What type of bearings are best suited for a spindle.

By 8iggles in forum Spindles & Drive MotorsReplies: 18Last Post: 09-02-2011, 10:15 PM

Reply With Quote

Reply With Quote

Bookmarks