Thread: Outrunner Spindle Parts?

-

04-08-2012 #1

The 200 watt spindle on my CNC3040 went pop today. It was my own fault; I was trying to clean up a part during cutting and got a cloth caught on the cutter. It didn't like flinging it around.

So, I'd like to build a new spindle with an outrunner motor and ER11 chuck. Something around 600watts.

My first question is what do I actually need? I know I need a motor and a speed controller, but do I need something to 'drive' the speed controller? I read something about using a servo tester. Secondly, what is this 'Li-Poly 2-7 cells' stuff? Why don't they just say the voltage it runs on?

As I have a non-functioning machine right now I'd like to get parts from the UK to get quick delivery. Any tips on where to get motors, speed controllers and chucks from?

Thank you :)

-

04-08-2012 #2

Arguably the most important specification is what spindle speed range do you require?

You need motor, chuck, angular contact bearings, housing made for bearings, ESC, something to control the ESC - servo tester is simplest.

They rate them by LiPo cells since that's what 'normal people' use to power them, which is understandable to avoid confusion for the target audionce, but equally annoying as it introduces uncertainty. 1 cell is nominally 3.7 volts, but 4.2v when fully charged so the ESC will tolerate up to 4.2v per cell.

-

04-08-2012 #3

So this controller for example can be run up to about 28V? I guess then, for efficiency it is better to run at a higher voltage and use a motor with a lower Kv spec? e.g. better to run a 4000Kv motor on 20volts than an 8000Kv motor on 10volts.

I don't know what speed range since the other motor never said! Any idea what is suitable for slow cutting of aluminium and routing wood?

-

04-08-2012 #4

http://www.mycncuk.com/forums/diy-pr...s-spindle.html

it might be worth having a butchers at this thread

the larger motors is 240kv so will run upto 2800rpm on 12v and has plenty of torque sub 1000rpm, works well on ally (iv not tried this on 24v but im sure it would handle it ok if you can stop the ESC getting too HOT)

the next one down in size is 820kv (upto aprx 10000rpm 12v) and will cut ally with 3mm tooling

-

04-08-2012 #5

I fitted a DC Ampflow 1/2hp motor to my Roland mill and discarded the AC screamer. Ampflow squeeze a lot of oomph into a small package.

I drive the spindle at 3000rpm with a toothed belt so it still screams, but not so badly. Question is, what do you use for a non-screaming belt drive?

Ampflow Motors and Motor Controllers

-

05-08-2012 #6

Thanks for the info.

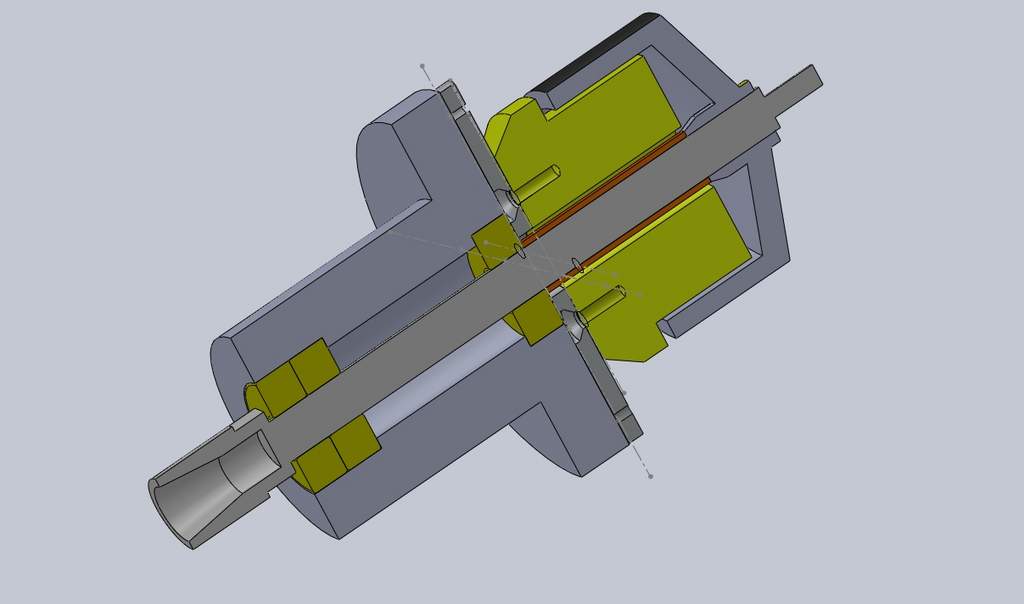

I wish to build something like the below picture, where the 8mm motor shaft is replaced with an 8mm shank er11 collet chuck. However I'm wondering about two questions.

1) How does the shaft fix to the motor? What is involved in replacing the shaft exactly, just whack the original out with a hammer and pop the new one in with another whack?

2) Why use such a long section of shaft extending from the bottom of the motor and then support it with additional bearings? Why not mount the chuck as far into the motor body as possible and dispense with the additional bearings? Like my hacked picture below.

-

05-08-2012 #7

1) grub screws in the bell housing grips the shaft

2) its to remove ALL the play that you would normaly get with any plain brearing (translates into poor finishes & poor cutting performance)

the nature of cutting promotes resonance in a big way, it would be interesting to see how well you would get on with the simplified design you propose so it may be worth giving it a go if your only cutting wood

if you want a good finish on plastics and ally im pretty (99%) sure you would be disapointed

-

05-08-2012 #8

The standard 200watt motor that is blown only uses 1 bearing at each end... but then it isn't necessarily a good item to copy!

Edited to add... so what sort of bearings do I need to get? It would be nice to use ones with an outside diameter that fits a standard drill, so would 8mm ID x 12mm OD be suitable?Last edited by Tenson; 05-08-2012 at 04:03 PM.

-

05-08-2012 #9

i would assume that those two bearings are angular contact bearings or its a cheap spindle with deap groove bearings

a typical hand wood router would have bearings that reflect the lack of need for exotic bearing setups

a dremmel tool would be the same... very good at what its designed for, attach it to a cnc router and the bearing slop may well show (dependant on the job your asking it to do)

i lost bearing tension on one of my diy spindles and it took me ages to work out why i was getting a crap finish whilst fly cutting acetal

the play was tiny... the effect was an unusable finish

your cnc may be capable of extreme accuracy and have splendid stability... it would be a shame to throw that away on sloppy spindle bearings

that does not mean you shouldnt make the simplified spindle

just bear in mind the implications :)

-

05-08-2012 #10

So, do I need angular contact bearings for the spindle? It isn't too much work to make the extra support part. I think I'll still make it short though, perhaps them I only need the two bearings at the end. The original design used deep groove so I think I'll do the same. I can't find any angular contact types with such a small ID as 8mm.

Last edited by Tenson; 05-08-2012 at 06:00 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Chinese 300W DC spindle - is the spindle shaft grounded?

By HankMcSpank in forum Spindles & Drive MotorsReplies: 44Last Post: 26-11-2016, 07:25 PM -

2.2kw spindle parts

By Tomnewry in forum General ElectronicsReplies: 3Last Post: 14-12-2013, 09:30 PM -

CNC Spindle Repair and Spindle Replacement for any Machine of any Manufacturer

By spindeldoctor in forum Manufacturer NewsReplies: 0Last Post: 13-11-2013, 07:50 PM -

FOR SALE: ER20 DIY Spindle Parts

By Mad Professor in forum Items For SaleReplies: 1Last Post: 03-11-2012, 06:51 PM -

DIY Spindle - What type of bearings are best suited for a spindle.

By 8iggles in forum Spindles & Drive MotorsReplies: 18Last Post: 09-02-2011, 10:15 PM

Reply With Quote

Reply With Quote

Bookmarks