Thread: 3-Axis CNC Mill Project

-

27-08-2012 #11

You could turn the open frame into a cupboard to keep your knick-knacks and controller in. If you cut Melamine faced board to a good fit on 3 sides it would make that base totally rigid.

Beware the temptation to make the gantry tall for that large lump you think you might want to cut some nebulous time in the future. Height costs you rigidity.

Your tool is unlikely to extend much more than an inch from the collet so you'd only be scratching the top of that lump anyway.

-

The Following User Says Thank You to Robin Hewitt For This Useful Post:

-

27-08-2012 #12

I've made a little more progress this afternoon.

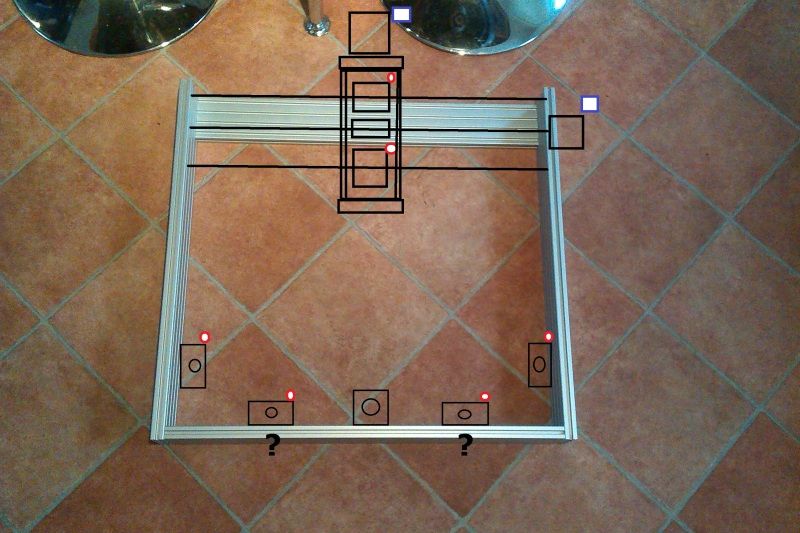

I've finished a mock assembly of the carriage. This is subject to being shortened on the height as much as the finished design will allow so that I can still get a good travel in the Z axis (up and down).

As a contingency factor Iím considering the prospect of using 4 linear rails in the X axis rather than just 2. This isnít my first choice though as it costs more. BUT if I can get good stability without drastic effects from inertia of the carriage rapid traversing then I'll leave it with just 2. There will always be the option to upgrade to the 4 though so that will be a bonus if like said required.

Just doodled over a picture if any can canít understand what Iím babbling on about, the square blocks are the linear bearing blocks and the ď?Ē are the extra ones factored.

The side supports like said are subject to being shortened as much as I can with the top brace to follow suit so the set up is as pictured, just shorter.

Next thing to do will be to order some hardened rails, support brackets and linear bearings and take things from there as and when funds allow or the missus signs my pass to take over the kitchen.

-

27-08-2012 #13

Ok I'll shoot first.!!

Please take what I'm about to say has help rather than pulling a design down.!!

That gantry is miles too narrow and it 99.9% will twist and rack even if you use 4 bearings in the arrangement you show. It will 100% rack if you use a single down the centre ballscrew using this arrangement.?

It does need 4 bearings but not like you have them drawn. They need to be in-line side by side creating a wide foot print.

The gantry cross bracing (Y axis) is no where near enough and it will flex with Y axis sides ways movement, 2 of those pieces would work much better.

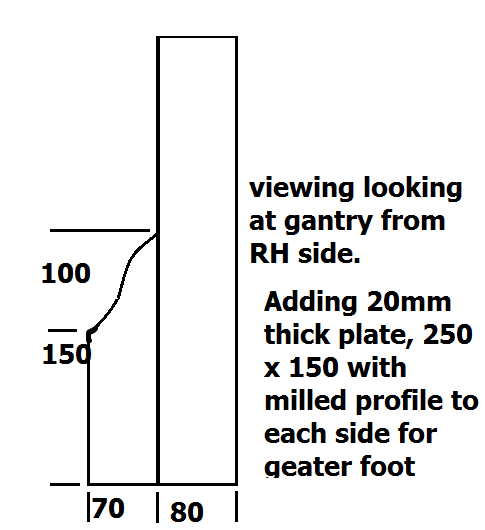

If you are going to use this narrow profile then I would recommend you fasten wide plates at the bottom for the bearings to mount side by side.

Also some corner bracing wouldn't hurt.

Don't know where your inspiration for this machine comes from but it has a very Merchant dice feel to it and if so then let me tell you they are rubbish design which flex and move around like quivers jelly.!!

-

The Following User Says Thank You to JAZZCNC For This Useful Post:

-

27-08-2012 #14

-

27-08-2012 #15

-

27-08-2012 #16

-

27-08-2012 #17

I fully take on board your comments jazz.

I can see now with slightly less blinkered eyes that the opinions so far have a good grounding behind them.

My only option is to start from the original sketch, assess and improve where ever i can.

Even if it serves no greater purpose than an expensive learning curve and thats the only benefit ive gained from doing this project at least i can put that expirience under my belt.

As for the merchant dice thing yes i did look at those, and designs from youtubers, neo7cnc and hamrx8 for some of the inspiration for my design, that and i was able to come by the aluminium i have used for free has left me with what i have.

Im not too disheartened, but will glady accept any furth help your willing to offer.

as for the greater foot print for the base in x, how about if i mount two pieces of 40 80, long side vertical, inside the frame, top edge of the 40 on the same plane as the under edge of the table top, and on these pieces mount each side a linear rail to meet 4 linear bearings on the carraige that way?

thanks again.

-

27-08-2012 #18

The base is not so much an issue and easily sorted with bracing or like Robin suggested stiffening with panels.

The tall narrow gantry is the biggest weak area I see and is where all the action takes place. It's also where all the other machines of similar design fall down.!

If your having a single central screw then you need a wide bearing footprint to help counter racking when cutting at the outer edges. The wider the better but obviously this loses travel so it's always a compromise.!

The other area that is often over looked and is THE most important part of the machine IMO the Z axis. It does all the work so if this is flimsy then it don't matter if the rest of machine is carved from one lump of granite the finished result will be shite.! . . . Obviously this is fastened to the Y axis and again if the gantry is flexing around because it's too tall or narrow and under braced then so will every thing attached to it.!. . . . It's also what Robin was pointing out.!

It's really just a case of make the X axis bearing foot print has wide as you feel you can spare and make the gantry only has high as you really need. If you need high then build very rigid with loads of bracing.

Don't under estimate the inertial forces of the gantry and Y/Z axis they can be quite high and will easily rock and flex a high narrow gantry at half decent cutting and rapid speeds.

This is what plagues the Merchant dice type offerings because the motors and Ball-screws are capable of so much more than the frame will allow and the finished cut is drasticly reduced if run too high.!! . . . So therefore the machines run feed rates well below there components potential to give anything like a decent finish and stop the frame from falling apart.!! . . . . This soon becomes very limiting and restrictive and why most sell them shortly after buying.!

My suggestion is you Stand back a little have a think and look about at other machines and throw a drawing or two our way for checking over. Has you've probably seen already where all more than willing to help and advise with honest opinions.

-

The Following User Says Thank You to JAZZCNC For This Useful Post:

-

29-08-2012 #19

Starting to see the error of my ways so far. Taking time out to work on some things. Will update once progress is made.

-

31-08-2012 #20

Does this look like a good place to start for improving the gantry, im thinking of shortening it to 450mm from 600mm, adding these supports shown, and also large braces at the top in Y, and corners all round.

thanks

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Emco mill 50 Y axis travel?

By gavztheouch in forum Emco Milling MachinesReplies: 0Last Post: 01-03-2014, 11:10 AM -

WANTED: 3-Axis Mill recommendations

By TomB in forum Items WantedReplies: 0Last Post: 05-10-2012, 10:06 AM -

NEW MEMBER: Goal - Enable 3-Axis CNC Bed Mill to Perform 5-Axis Milling

By LoveLearn in forum New Member IntroductionsReplies: 2Last Post: 25-01-2012, 08:46 PM -

FOR SALE: Mini Mill Z-Axis stuff

By pjm in forum Items For SaleReplies: 0Last Post: 17-06-2010, 10:00 PM

Reply With Quote

Reply With Quote

Bookmarks