Thread: Scrap Heap Challenge

-

11-09-2012 #21

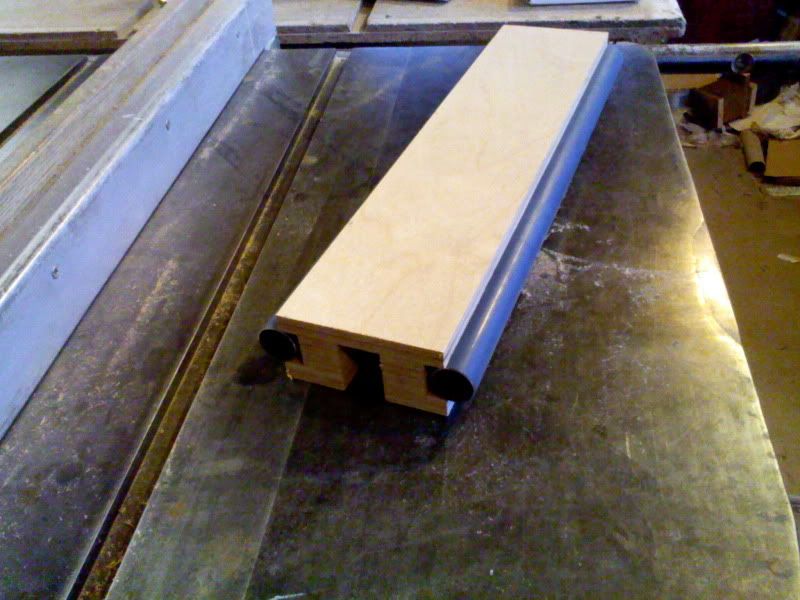

:) finally got started on the Z today

I'm still making it up as I go along, depending on what I can find to make it out of !

Today, it was 1/2" birch ply.

the bearing trucks and rail are quite wide, and as I dont want to build out any more than I need, towards the front, the Z plate ended up quite a bit narrower than I imagined. It's still 4", so should be ok.

In fact, it ended up just like an idea I had the other day of making your own Hiwin type rails and bearings.

I have it mostly assembled and glued under preload from a clamp. It moves really nicely.

Tomorrow, when the glue is set, I'll be adding more glue block support to the outside edges, behind the bearings. the pipe is not attached yet, so I can shim under it if needed.

Also, not shown in the photos, I block planed the rail housing edges so the pipe fits in it's slot snugly and seats on the bottom.

CLICK TO PLAY

-

11-09-2012 #22

T

I got a bit done today.

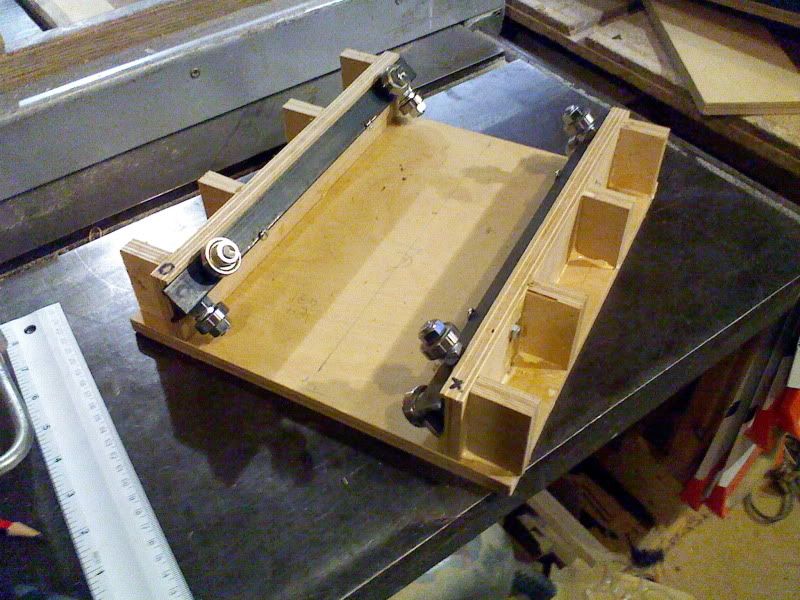

Screw and nuts sorted.

I'm going to mount the motor to the Z plate, and was looking at the space I had to mount the nut(s) for the allthread screw.

I have just enough room for the nut, but not much more. so this ruled out a nut surround.

My 1st thought was to weld the nuts to a small bit of 1" x 1/8" flat bar, but my welder is well packed in under a load of "stuff" in the corner of the shop. So I'm wondering how to hold the nuts in posistion without using any space around them. The nuts are quite meaty, so I had the idea to drill and tap through the side of the nut, and hold it in place with a bolt, through the bottom of the bearing carriage . I didn't know if it would work, or what the nuts were made of ? could I drill them ? would they be too hard ?

Anyway, it seemed to work OK. I tried a bit of spray can to mark the bolt that protruded through, but it didn't stay on when I removed it, so a bit of fussing, and I had the bolt ground down to the correct length where they wont foul the leadscrew, but have maximum purchase on the nuts.

I didn't really take the time to have the nuts alighned, instead, I left them slightly loose, threaded the leadscrew through both, set the leadcrew in the correct posistion and 5 min epoxy'd the nuts in place. once that had set, I tighten the bolts that hold the nut. Time will tell, but I see this as a temporary setup until I get a better screw and antibacklash nut.

So, onto the screw. I wasn't sure how the end should be, so I made it look like pictures I'd seen on here and online CNC shops.

It's the 1st time I've used a lathe, so was happy how it came out.

It's M12 allthread rod, skate bearing, M8 nut, and 1/4" coupling bit on the end.

The lathe cost me about £100 UK pounds and is about 100 yrs+ old !

I think it will pay for itself very quickly :)

So, I still have the bearing blocks and couplings to make, they'll be next.

Still not cutting, but getting there ! It seems to be taking longer to make the Z than the rest put together ...

[

[

-

11-09-2012 #23

so, not go much done today. I have designed my bearing block and motor mount (in my head) using what I have lying around.

the skate bearings OD just happens to be 22mm, which I have that size in a spade bit. 22mm counter bore in two bits of MDF, with 16mm through bore for the nut and screw clearance, and I have two halves of a fully encapsulated bearing block ... simples :)

I'll make the real one from birch ply. One half I will mount to my Z plate, the other half to my motor mount. They will be bolted together, so they can be split any time, to get at the bearing if I need to.

That's the general idea anyhow :)

I'll try and get that together over the weekend. Then it's just a router mount I guess, and then some cutting :D

-

11-09-2012 #24

[Z attatched.

I made the coupling out of wood, so I'm not sure it will grip. but it's progress for now

[/

[/

-

11-09-2012 #25

]router mount made ....

just got to wire up the Z, and I can test it :D

Maybe today is the day ?

-

11-09-2012 #26

]Got the router mounted. (I know I should have waited until tomorrow for the glue to set .... )

Got the Z wired up, only to find it moving in the opposite direction. ???

Swapped a and b coils, and all is good now..

sorry - held my phone the wrong way up without thinking for these

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid121.photobucket.co m%2Falbums%2Fo238%2FRichAAC-UK%2FMOV00014.mp4">

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid121.photobucket.co m%2Falbums%2Fo238%2FRichAAC-UK%2FMOV00012.mp4">

Not done any tuning on the Z yet, but it carves :D

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid121.photobucket.co m%2Falbums%2Fo238%2FRichAAC-UK%2FMOV00013.mp4">

It carved deeper one end than the other, but I only had it clamped at the edge - off the bed, and I did notice it was lifted towards the other end.

I'll investigate tomorrow, (It's night time here now )

but

:D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D :D

:wee:

-

11-09-2012 #27

]so, been playing with some free software.

Inkscape with gcodetools can do pathcutting and V-Carving.

I surfaced a spoilboard (did I say that already ? ) and recut the EMC demo

that turned out pretty good.

I worked out how to do V-Carving with inkscape, and cut a Pet Cross, with the name MAX on it. The biggest problem I had, was figuring out where to position the pre made cross, to get the carving in the correct place. It ended up being low of center, but the carving itself was quite neat. It did look very 'machine cut' though, and I do prefer the hand carved look. I'll have to change the wording in my sales pitch !

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid121.photobucket.co m%2Falbums%2Fo238%2FRichAAC-UK%2FMOV00015.mp4">

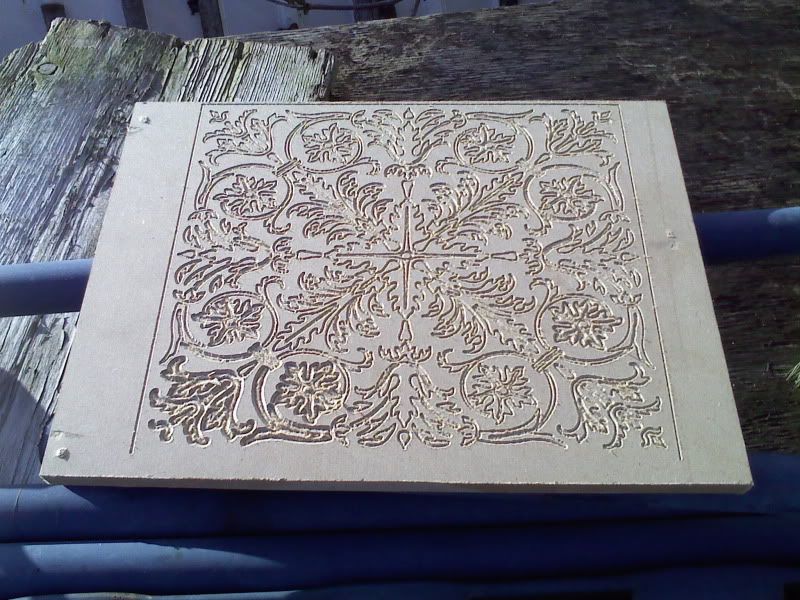

then I tried a tile pattern on a scrap of MDF. It was about an hour to cut, and I noticed it start cutting deeper in the lower left corner. I suspected the Z motor coupling, so marked it, and marked the top motor shaft corispondingly. Sure enough, the coupling was slipping. I tightened it up and continued cutting, which seemed fine to the end.

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid121.photobucket.co m%2Falbums%2Fo238%2FRichAAC-UK%2FMOV00016.mp4">

the end result was pretty good for a test. I used just plain path cutting. I think V-Carving would have been better.

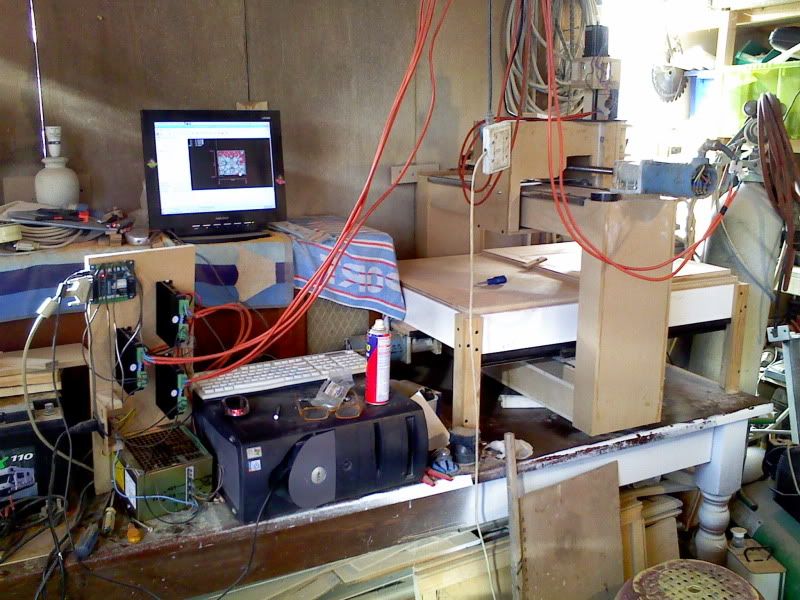

I need to start tidying up the wiring, and locktighting the nuts and bolts. The odd one is coming loose already !.

This is the machine as it stands today.

I had to switch off, and do some paying work, so no more playing for a bit :(

Thanks for looking

Rich[

-

11-09-2012 #28

And that's about it.

I've painted a few more bits and added a new spoil board and fence, but I've been using it like this now, every day for about 6 monthsI'll tidy

up the broken links over the next week or so, but this just about covered my 1st CNC build from scrap and bits of wood :)

I'm happy !Last edited by TrickyCNC; 11-09-2012 at 11:05 PM. Reason: sp[ling :)

-

14-09-2012 #29

looks awesome.. do you think it's going to stay in mdf or do u think over time you will recut pieces in to alu to add strength?

-

14-09-2012 #30

Thanks Wilfy

I think this one will stay MDF. I'll fix/change the sloppy bearings, which is where I get most of the movement, and then see if the MDF is moving / flexing at all. But at the moment, I cant see any movment in the gantry or risers. Remember, it's intended to cut wood ! If I want to cut metal, I'll build one to suit.

I'm saving for another driver/motor kit and I'll be building a 8' x 4' working area machine. I'll be making that in MDF or PLY too, as this "test" build has proved it to be sufficient.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Recycle electronics or scrap?

By gavztheouch in forum General ElectronicsReplies: 2Last Post: 05-02-2014, 04:16 PM -

BUILD LOG: Definately a scrapyard challenge

By motoxy in forum DIY Router Build LogsReplies: 158Last Post: 29-10-2012, 10:12 PM -

NEW MEMBER: Up for a challenge......

By swatt in forum New Member IntroductionsReplies: 1Last Post: 03-10-2010, 10:57 PM -

Fancy a challenge?

By cassius in forum Machine DiscussionReplies: 5Last Post: 03-09-2010, 02:44 PM -

BUILD LOG: Work scrap bin router build

By Vic66 in forum DIY Router Build LogsReplies: 32Last Post: 17-01-2010, 08:51 PM

Reply With Quote

Reply With Quote

Bookmarks