-

21-11-2012 #1

Gents,

I'm planning to use two steppers in a design of mine and I'd like to double check a few things before I go on a buying spree:

Stepper 1

Probably a Nema 23 stepper, which will run continuously, but in shorts bursts (so for example 20-30s at a time, with minute brakes between). It will drive a shaft via a toothed pulley, ratio will be 2:1 (stepper being faster than the shaft) or 1:1 depending on how smooth I can get the motor to run or how powerful the motor is. Overall operation doesn't really need a stepper and I'm curious if I can use one as a driver for the shaft? the reason for this is that I can get pretty high torque for not a lot of monies (I'll need stepper control, but I'm using another stepper anyway, so a controller can cover both of these). This might as well be modified to be a DC motor instead. Shaft load will be minimal ie. handcrank levels.

Stepper 2

Needs to be a small unit, so looking at a Nema 14. This will drive an M10 lead screw, which will be used to lower and raise an assembly which weighs around 2-2.5kg via two lead blocks. This one will work a microstep at a time as the assembly needs to be positioned precisely (via buttons I reckon), speed isn't an issue. It will also only work in a rather tight area, 5mm tops of total movement, so with a standard pitch of 1.5mm this will be around 3 turns max. I can get around a 10Ncm torque from these Nema 14 steppers, but I'm not sure it's enough to lower and raise a 2-2.5kg assembly. No cutting forces will be present, there might be some small side forces acting on the assembly, but it's supported on two linear 10mm rails, so I guess that will prevent twisting etc. What I need from it is to move and hold the assembly dead in one place, nothing more.

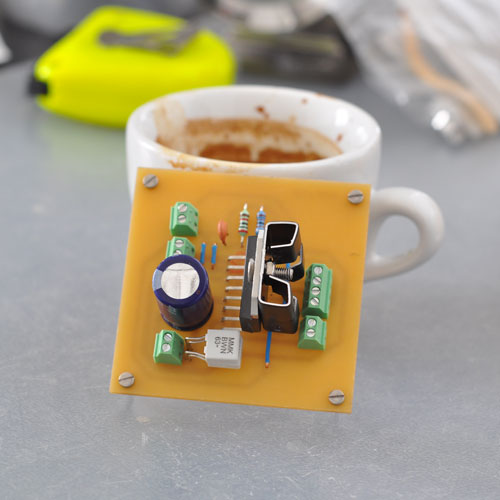

If anyone can suggest torques needed or simply thinks the above is crazy, please let me know:) controller of the motors will be via a custom built electronics unit. I've tried my luck in doing a circuit to run a stepper using LMD chips, but that ended rather badly in the chips overheating (maybe a PCB short or smth similar):

so I might just get a controller of the shelf and do the electronics for the interface instead using a uC. Has anyone tried doing that? controlling a controller and the steppers using a uC circuit instead of a PC?

Cheers,

dsc.

-

21-11-2012 #2

i'm not sure what uC is and its hard to picture exactly what your aiming for (i guess its commercially sensitive) however, if your talking along the lines of running from a pic this might give you some ideas

http://www.mycncuk.com/forums/diy-pr...-indexing.html

iv just splashed out on a pickit3 programmer... haven't got a clue what i'm doing at this point (besides making LED's blink)

I might have a go at building something along the "indexing" lines when iv got over the "hello world" side of programming :)

-

26-11-2012 #3

Hi Mark,

late reply, I forgot about this thread;)

You guessed it, it is a bit commercially sensitive, hence the rather limited details. Main questions I wanted to focus on where:

- if a stepper can be used as a driver for a shaft at low speeds and low loads

- how one calculates needed torque for a stepper, knowing what the downward pull / load would be

uC is a microcontroller, so basically like a PIC, Atmel or an Arduino.

Regards,

dsc.

-

26-11-2012 #4

Yes, so long as the loads are actually low as steppers do not output much torque for their size.

The formula, which can be derived from considering the ballscrew 'unwrapped' to become an inclined plane is:

T=(F*L*e)/(2*pi)

Where T is the required torque, in Nm, L is lead (or pitch of the screw) in meters and e is the efficiency which I think is about 0.3 for a threaded rod leadscrew drive.

-

The Following User Says Thank You to Jonathan For This Useful Post:

-

26-11-2012 #5

Cheers Jonathan!

Hmm might go for a small DC motor instead to get a bit more torque and run the shaft. The only reason why I thought of steppers for the driver is because I thought I might use a stepper controller, which normally covers 4 steppers. I could then interface with the controller using a microcontroller based circuit via an LCD interface, although I'm not sure how easy that is. I think most controllers are plugged into to a PC via an RS232 / 485 port, so I'd need a circuit which handles that, or it might be easier to build a stepper controller using LMD18245 chips and integrate everything into a single circuit.

Based on that formula for the torque, the value comes out rather small:

F = 3kg * 9.8mm^2/s = 29.4N

L = 1.25mm = 0.00125m

e = 0.3

T = (29.4N * 0.00125m * 0.3) / (6.28) = 0.00176Nm = 0.176Ncm

which is way below even the smallest Nema14 motors, so it's not bad news. Unless of course I've messed it up somewhere.

Regards,

dsc.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

screening / glitchy operation - sanity check

By dsc in forum General ElectronicsReplies: 21Last Post: 01-12-2013, 11:35 PM -

Video of Solids of Constant Width

By M250cnc in forum Metalwork Project ShowcaseReplies: 18Last Post: 12-11-2013, 11:18 AM -

maximum deflection - sanity check

By dsc in forum Gantry/Router Machines & BuildingReplies: 6Last Post: 11-02-2013, 09:33 AM -

Toroidal transformer voltages - sanity check needed!

By m_c in forum General ElectronicsReplies: 16Last Post: 03-10-2011, 08:34 PM -

Laser Diode Constant Current Driver

By Mad Professor in forum General ElectronicsReplies: 8Last Post: 21-07-2010, 06:01 PM

Reply With Quote

Reply With Quote

Bookmarks